Rivian Q2 2025 Financial Report: Navigating US EV Policy Shifts - The Endurance of New Players

![]() 08/14 2025

08/14 2025

![]() 652

652

Produced by Zhineng Technology

In the second quarter of 2025, Rivian's focal point was not sales but preparation. The R2 platform's launch entered a substantive phase, marking a pivotal engineering milestone for a company still transitioning from the high initial investment stage of vehicle manufacturing.

Over the past three months, the American newcomer successfully completed the design verification manufacturing (DV) of R2 prototypes on its pilot line in California and advanced the expansion of its main factory in Illinois by over one million square feet to accommodate future vehicle assembly lines. The planned three-week temporary production halt has been confirmed for production line switching and equipment debugging—a standard but crucial process.

Additionally, Rivian commenced deliveries of the R1 series equipped with the second-generation quad-motor system, with the technology platform's update progressing as anticipated.

This strategic move is clear: leveraging flagship models to navigate complex technical challenges and then leveraging the more scalable R2 platform to expand delivery volumes and enhance cost control.

While this quarter's financial results were modest, Volkswagen's capital injection provided a much-needed respite. For Rivian, the primary objective this year is to finalize the platform, streamline production lines, and identify the next pivot point.

01

Eve of R2 Platform Launch: Design Verification and Manufacturing System

From a technical product cycle perspective, the R2 platform has now entered a crucial verification phase, signifying the acceleration of Rivian's second-generation platform from engineering design to mass production.

Rivian has initiated the manufacturing of R2 design verification models (DV prototypes) on its pilot production line in California. These vehicles are pivotal for assessing design performance during actual manufacturing and testing, laying the groundwork for the final engineering verification (EV) and production verification (PV) stages.

From a manufacturing system standpoint, Rivian's factory in Normal, Illinois, has undergone an expansion of 1.1 million square feet, primarily earmarked for the layout of the R2 production line. Currently, production line tooling is being installed, with commissioning expected to conclude and equipment verification to commence in the third quarter of 2025.

This information indicates that the R2 mass production plan adheres to a typical new automotive platform introduction sequence: DV phase → production line tooling → three-week temporary production halt → production line switch → process verification → mass production.

Rivian will temporarily halt its existing production line for three weeks in September to undergo renovations, enhancing the plant's overall capacity to 215,000 vehicles annually.

This decision underscores that the R2 production line represents a comprehensive capacity structure upgrade rather than a localized expansion. Such a layout also offers flexibility for future co-line production of derivative models, aiding in reducing unit costs, enhancing yield rates, and increasing component commonality.

In terms of cost optimization, design verification models are manufactured on the California pilot line to ascertain whether modular design can achieve high repeatability manufacturing even in low-cost production lines.

From an engineering perspective, the current focus is on balancing material costs, the path-to-manufacture, and quality closed loops. Based on the announced information, the R2 platform signifies not just a new product but also a systematic reconfiguration of engineering processes, which is pivotal for Rivian's long-term gross margin improvement.

In this quarter, Rivian commenced deliveries of the second-generation quad-motor R1 series, marking the completion of an upgrade to its core electric drive technology system. The quad-motor system remains a hallmark of Rivian's electric drive strategy, distinguishing it from the mainstream dual-motor structure and offering unique advantages in off-road performance and driving control.

The second-generation quad-motor system emphasizes three key improvements:

◎ Optimized Power Integration and Responsiveness: The new system anticipates integrated upgrades in the motor control unit (MCU) and power modules (like SiC inverters), reducing response time and enhancing the precision of independent torque control for all four wheels, particularly on unpaved roads or in low-adhesion scenarios.

◎ Driving Efficiency and Thermal Management: Compared to the first-generation system, the new quad-motor version is more optimized in terms of structural lightweighting and thermal management system deployment (including integrated cooling channels and independent thermal cycles). This extends peak performance duration and enables the system to maintain stability in high-power output scenarios over extended periods.

◎ Driving Pleasure and Control Strategies: The quad-motor system supports real-time torque vectoring, enabling the vehicle to distribute driving force among different wheels based on the driver's intent. For instance, in off-road driving, climbing, or rapid lane changes, the system can independently control the rotation speed and torque of the four wheels, creating a "software rear lock" effect akin to a mechanical differential lock system.

Compared to the traditional dual-motor structure, the quad-motor platform aligns better with the brand positioning of high-end electric vehicle models. As Rivian's flagship product, the R1 series adopts a quad-motor setup, emphasizing its product philosophy centered on performance and control. The quad-motor setup also underpins Rivian's unique features such as "Tank Turn," helping it differentiate technologically from other pure electric brands.

While the quad-motor structure involves more components and higher costs compared to traditional architectures, its long-term potential lies in the trend of "control algorithms + hardware decoupling," where future complexity can shift to the software layer, achieving bidirectional optimization of mass production efficiency and functional iteration.

02

Financial Performance and Rivian's Value

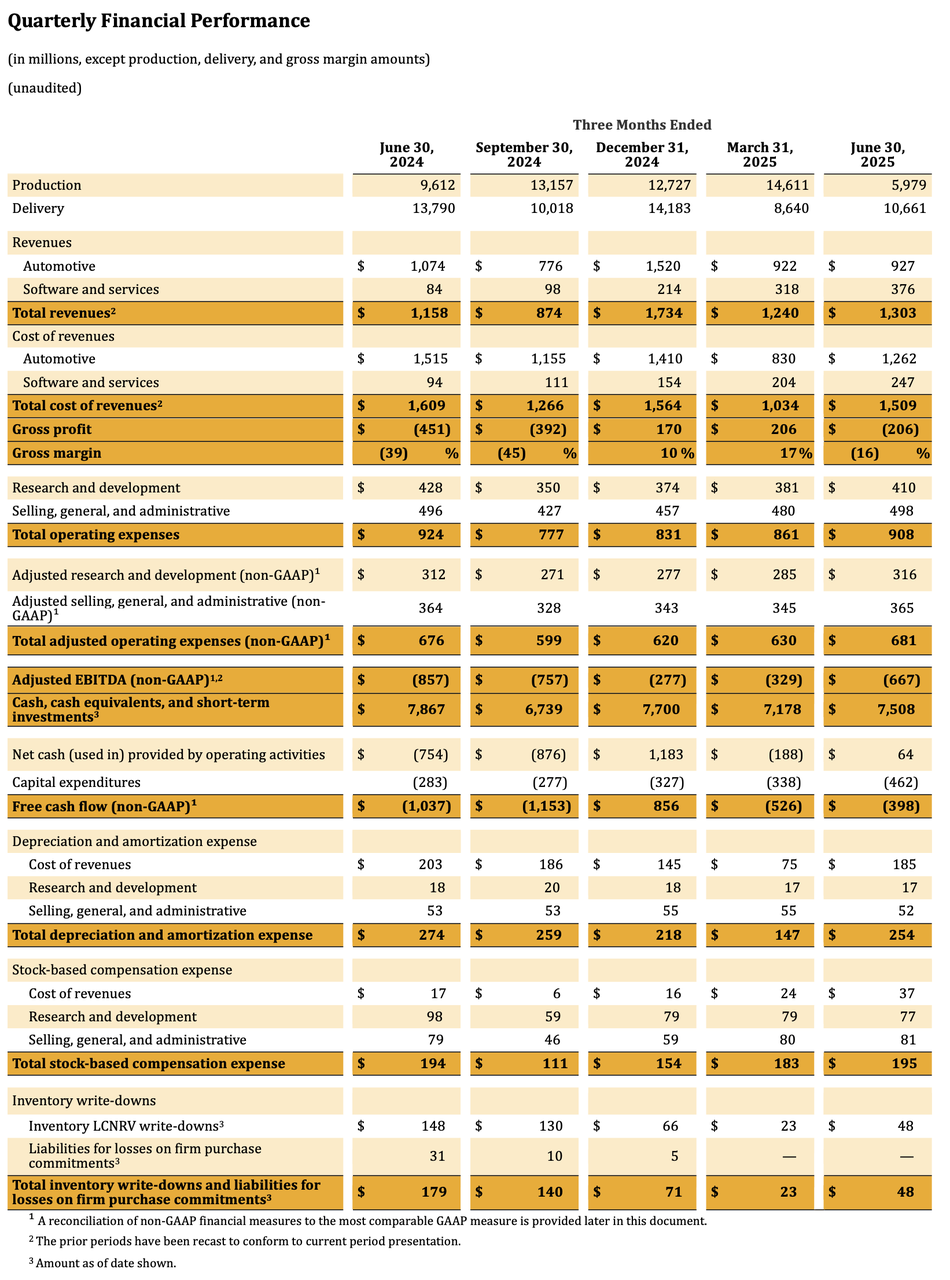

From a financial perspective, Rivian delivered 10,661 vehicles in the second quarter, a slight increase from the first quarter, with production volumes at 5,979, lower than deliveries. This mismatch stems from Rivian's strategic priority of ensuring existing model deliveries while preparing for the 2026 model production switch.

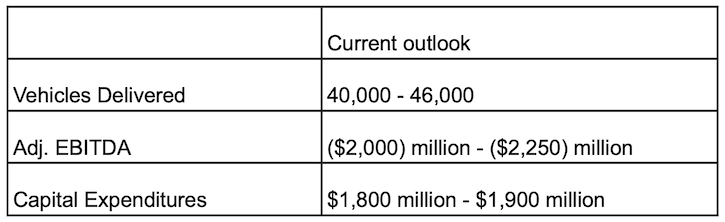

Amid trade policy changes and increased supply chain uncertainty, Rivian has maintained its full-year 2025 delivery target of 40,000 to 46,000 vehicles.

The second quarter marked the second consecutive quarter of positive gross margins, albeit modest. From an operational cash flow perspective, sustained positive gross margins signal potential for subsequent cost reduction and efficiency enhancement.

Regarding capital structure, the most notable event was Volkswagen Group's $1 billion equity investment in Rivian on June 30 at a subscription price of $19.42, a 33% premium to the then-prevailing market average price.

This investment is the first under the joint venture agreement (up to a $5.8 billion cooperation plan), potentially paving the way for future joint technology research and platform sharing.

This funding round bolstered Rivian's cash structure, particularly mitigating financial pressure during the high capital expenditure phase.

In return, Volkswagen aims to accelerate its localization transformation in the US market by leveraging Rivian's manufacturing base and electric platform capabilities in North America. In the long run, this capital injection serves not just as a liquidity tool but as an entry point for deep collaboration in future products, research and development, and supply chains.

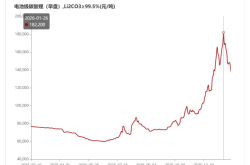

On the profitability front, due to credit policy adjustments and anticipated production cost increases, Rivian revised its full-year adjusted EBITDA loss expectations upwards from previous levels to between $2 billion and $2.25 billion. This reflects its realistic assessment of expenses during the ramp-up period of the new platform and indicates that its profitability model is still in the "amplified investment" stage.

Summary

In the second quarter of 2025, Rivian's primary focus was on paving the way for the R2 platform launch, completing prototype design verification, factory expansion, and production line switching plans while advancing the delivery of the second-generation quad-motor system for the R1 series. Financially, deliveries increased slightly, gross margins turned positive for two consecutive quarters, and Volkswagen's capital injection alleviated financial pressure, albeit with revised upward loss expectations.

Overall, Rivian is in a crucial period of technology implementation and capacity ramp-up. The smooth advancement of its platform and production line layout will determine its future growth potential in the electric vehicle market.