What Distinctions Exist Between LDD and OCT in the Online Monitoring of Laser Welding for Lithium-Ion Batteries?

![]() 01/23 2026

01/23 2026

![]() 557

557

Hello, everyone! I'm Buyan, and I'm delighted to be back. This marks my 192nd original article.

When it comes to the online monitoring of laser welding, both LDD (Laser Depth Detection) and OCT (Optical Coherence Tomography) technologies are utilized for real-time assessment of welding quality. Nevertheless, they differ substantially in terms of principles, functions, and applicable scenarios.

1. Technical Principles

1.1 OCT (Optical Coherence Tomography)

Principle: OCT operates on the principle of low-coherence interference. A beam splitter divides the light source into a reference beam and a measurement beam. The measurement beam is coaxially aligned with the processing laser and directed to the bottom of the keyhole. Upon reflection, it interferes with the reference beam. Through spectral analysis, the optical path difference is determined, enabling the direct measurement of the keyhole depth (i.e., penetration depth).

Precision: The axial resolution of OCT reaches 12µm, with a penetration depth monitoring error of ≤3.65%. It also exhibits focal length adaptability, with a standard deviation of only 0.072mm when subjected to ±2.5mm height fluctuations.

Applicable Scenarios: OCT is ideal for real-time monitoring of penetration depth fluctuations and keyhole stability, facilitating the optimization of the process window.

1.2 LDD (Laser Depth Detection)

Principle: LDD represents an industrial application of OCT technology, exemplified by IPG-LDD. It emits a broadband light source through a superluminescent diode (SLD), utilizing an interferometer and spectrometer to measure keyhole depth in real-time, with a sampling frequency of up to 250kHz.

Characteristics: LDD directly measures penetration depth but has limited adaptability to complex welding trajectories, such as oscillating welding, and is susceptible to interference from keyhole collapse.

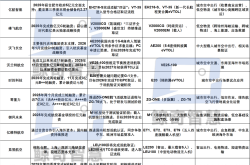

2. Functional Comparison

3. Advantages and Disadvantages Comparison

3.1 Advantages of OCT

OCT provides direct and highly precise measurement of penetration depth, along with robust anti-interference capabilities.

It can monitor macroscopic issues, including workpiece deformation, welding deviation, and surface defects.

OCT supports closed-loop control, enabling dynamic adjustments, such as modifying the defocus amount.

3.2 Disadvantages of OCT

OCT is unable to detect surface oil contamination or glue pollution.

During high-speed welding (>300mm/s), its precision diminishes, necessitating recalibration.

3.3 Advantages of LDD

LDD boasts a high sampling frequency (250kHz) and exceptional real-time performance.

Its automatic calibration function streamlines the debugging process, automatically capturing the keyhole origin.

3.4 Disadvantages of LDD

LDD has poor adaptability to complex welds, such as those involving oscillating welding or curved trajectories.

During keyhole collapse, LDD experiences significant measurement errors, with penetration depth dropping sharply by 0.4–0.8mm.

4. Application Scenario Recommendations

4.1 Prefer OCT

OCT is recommended for scenarios demanding high-precision penetration depth control, such as power battery top cover welding and seal nail welding.

It is also beneficial during process optimization stages, such as determining the optimal core-to-ring power ratio for annular spots.

4.2 Prefer LDD

LDD is more suitable for high-speed welding scenarios in automotive components, such as airbags and gears.

It is effective for equipment status monitoring, identifying equipment failures through abnormal penetration depth curves.

5. Joint Application Cases

Photoelectric + OCT Fusion Monitoring:

Photoelectric sensors detect surface defects, such as oil contamination and power attenuation, while OCT monitors penetration depth stability, achieving 100% full inspection.

For instance, in a power battery production line, photoelectric signals identify blowholes, and OCT verifies penetration depth fluctuations to comprehensively assess the risk of incomplete welding.

6. Conclusion

OCT excels in high-precision penetration depth monitoring and process optimization, whereas LDD performs better in high-speed scenarios and equipment status monitoring. In practical applications, leveraging the strengths of both technologies through multi-signal fusion can enhance the comprehensiveness of welding quality control.

The insights presented above are derived from my daily work, interactions, and literature reviews. Given my limitations, there may be omissions in the views expressed. I encourage active communication and collaboration with industry peers for mutual progress!