Xiaopeng Robot: Unveiling Its Tier through Global Comparison

![]() 11/07 2025

11/07 2025

![]() 631

631

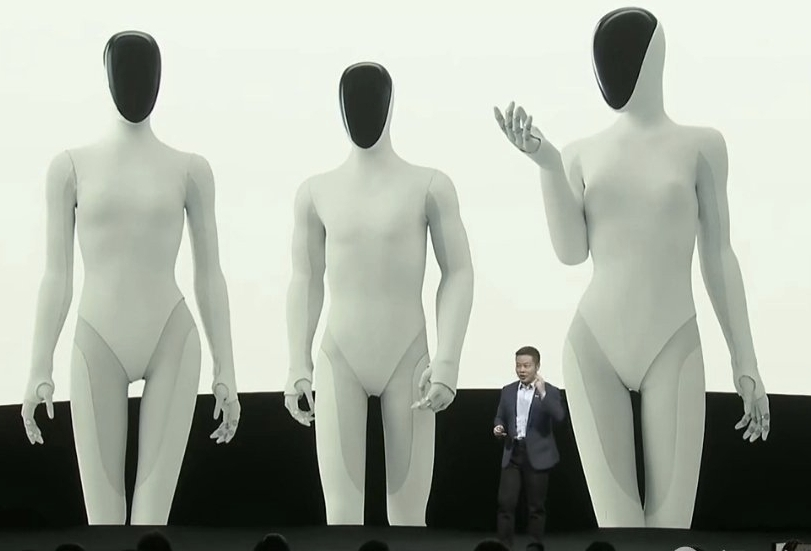

Yesterday, XPENG Motors made waves in the tech sphere by unveiling its latest-generation robot, IRON. The robot's uncanny resemblance to a real human immediately drew significant attention.

Upon a closer look, its physique, gait, ear shape, and other characteristics closely mimic those of a human. If it weren't for the continuous, uninterrupted video shot by the founder of XPENG Motors, doubts about it being a "real person in disguise" could have lingered for a long time.

Of course, while appearance is eye-catching, as tech enthusiasts, our focus should lie on its intrinsic value. So, what tier does the Xiaopeng robot belong to? What unique value does it bring? This article will delve into four key aspects.

- 01 - Flexibility and Precision

First, let's examine its physical hardware and design, which closely resemble human flexibility and execution precision.

The robot boasts 82 degrees of freedom in its body and 22 in its hands. What do these figures signify? Take Tesla Optimus, Tesla's humanoid robot, as an example. Its 2022 prototype reportedly had no more than 40 degrees of freedom in its body and around 22 in its hands.

Admittedly, this is a machine from three years ago. Let's compare it with the latest domestic robots.

According to Pencil News statistics, among the currently publicly released domestic robots, most have body degrees of freedom ranging from 20 to 50, with hand degrees of freedom rarely exceeding 22.

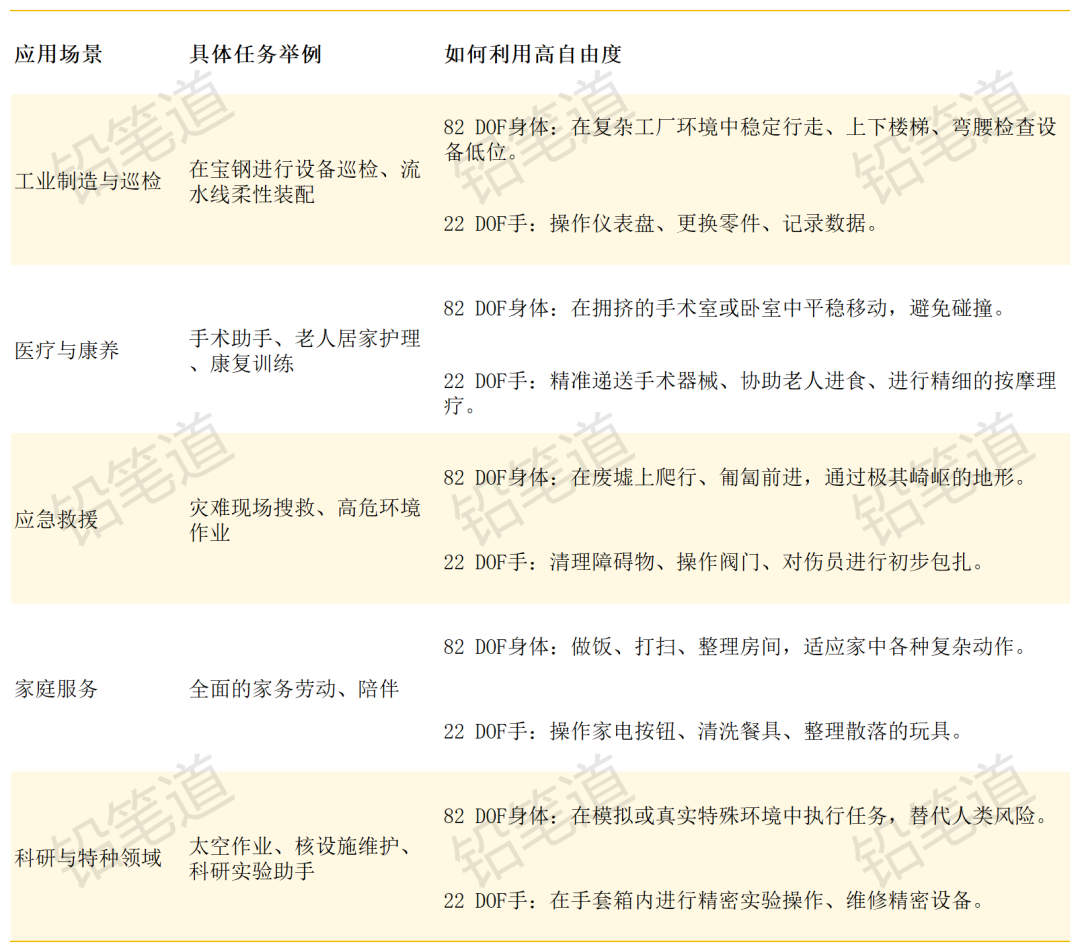

Some might question the significance of these parameters. The higher the values, the more adept the robot is at performing delicate operations.

With 22 degrees of freedom in its hands, comparable to human joint flexibility, the robot can grasp, pinch, twist, write, plug, and perform fine assembly tasks. Essentially, most jobs typically done by humans can now be performed by robots.

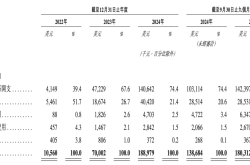

To aid in understanding, we present a set of charts.

It's crucial to note that while the Xiaopeng robot showcases remarkable flexibility, it's still far from being able to "work extensively for humans." Why? Because even with a highly flexible body, the "brain" must also function effectively.

We're referring to the robot's "brain intelligence level." The defining trait of humans is their ability to use tools. If a robot lacks intelligence, it remains a tool, not a human substitute.

For instance, can the robot understand human language? In this regard, large language models likely score the highest.

Secondly, after understanding the language, can it effectively comprehend tasks? For example, if asked to clean, can it plan steps like "first tidy the table, then sweep, and finally mop"?

Thirdly, how is its real-time decision-making ability? While walking, if a ball suddenly rolls in front, can it predict that "a child might follow" and immediately stop and wait? This might pose a challenge for current AI.

Finally, can it perform consistently? Occasionally completing a task is different from doing so reliably over the long term. This requires extensive data and algorithmic iteration.

- 02 - Screw Tightening Capability

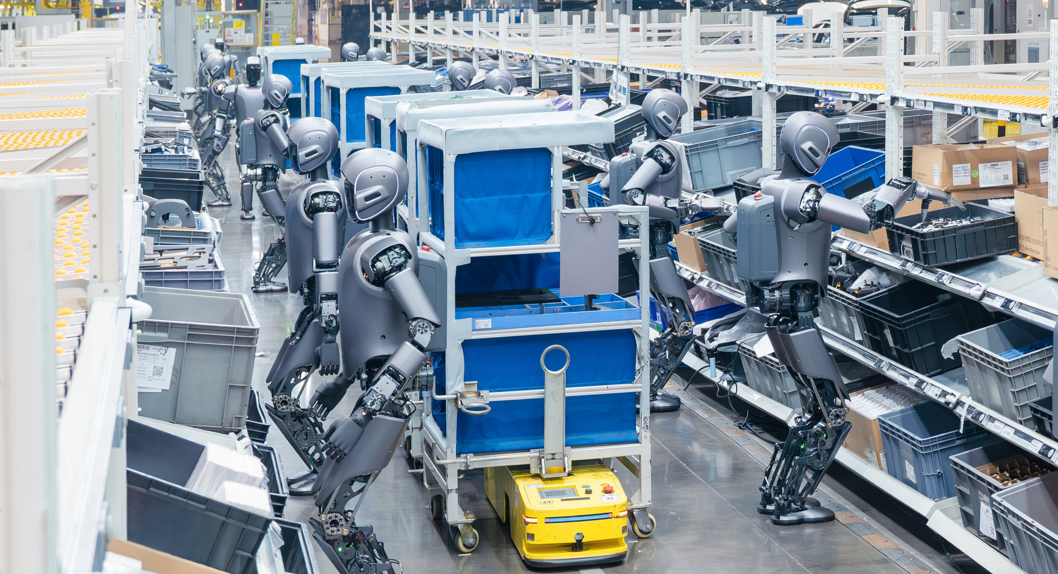

The second unique value of the Xiaopeng robot lies in its ability to work in factories, leading the way in commercialization.

The IRON robot has already been integrated into the production line at XPENG's Guangzhou factory, assembling components of the "XPENG P7+ model" by installing 500 screws daily and saving over 300,000 yuan in annual labor costs.

How significant is this breakthrough? After reviewing global cases, Pencil News considers it relatively advanced.

In Japan, Fuji Senko Kogyo Co., Ltd., a metal processing company, uses Kawasaki Heavy Industries' duAro robot for screw tightening. This robot can carry a 3kg load and achieve a repeat positioning accuracy of ±0.05mm.

Kawasaki's DuAro (Collaborative Robot)

Of course, this robot is not humanoid but a dual-arm collaborative robot.

In China, UBTECH's industrial humanoid robot, Walker S1, has also started working in factories. On electric vehicle production lines, Walker S1 has begun training and deployment for assembling components, tightening screws, organizing parts, and logistics handling.

Additionally, a South Korean media report stated that a company in Jiangsu, China, collaborated with Galbot to develop a "humanoid robot" for inspecting screw tightness and cable installation issues.

From these cases, it's evident that while robots working in factories are not a novelty globally, some are not humanoid, and some are only in training or inspection roles.

More importantly, the Xiaopeng robot is not limited to screw tightening; it has also partnered with Baosteel for industrial inspections, indicating its relatively advanced commercialization.

- 03 - Mass Production Stage

The third unique value of the Xiaopeng robot is its mass production capability. While advanced, it's not the only one in this regard.

IRON is scheduled for mass production by the end of 2026. Currently, several hundred humanoid robots have been deployed on XPENG's production lines.

Let's assess its global standing.

First, Tesla (Optimus). Elon Musk has publicly stated multiple times that limited mass production will occur between 2025 and 2026, with larger-scale production expected to begin in 2026.

Second, Figure (a Silicon Valley company). It has deployed the Figure 02 series in factories like BMW for pilot projects and is considered one of the few commercial trials to achieve "factory deployment" between 2024 and 2025.

Third, Apptronik (a Texas company). It has collaborated with Mercedes-Benz for trials and publicly stated its goal to begin manufacturing commercial units and expand production capacity in 2026.

Given this, if XPENG can achieve mass production in 2026, it should rank among the global leaders.

However, mass production is far from straightforward.

Take "consistency" as an example.

An industrial-grade robot may have over 1,200 components. For mass production, the consistency error of motors and drivers in these components must be ≤ ±1%.

This means every joint must maintain stable force control, position control, temperature compensation, and communication delay; otherwise, the robot may shake, drift, or be inaccurate. Mass-producing humanoid robots is a formidable challenge.

Despite the difficulty, it's crucial. Why? Because without mass production, prices will remain high.

Figure, Apptronik, and Tesla have all publicly mentioned that mass production is the only way to reduce the overall cost from six-digit to five-digit or even four-digit dollar figures. Otherwise, robots will struggle to demonstrate "cost-effectiveness," reducing customer incentive to purchase.

- 04 - Self-Developed Chip

The fourth unique value of the Xiaopeng robot may lie in the autonomous control of its core hardware.

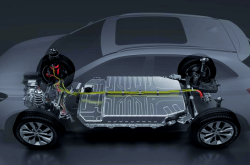

It is equipped with a (partially) self-developed chip—the Turing AI chip—with a computing power of 2250 TOPS, three times that of existing mainstream chips.

Many might wonder: Why develop a chip in-house?

In humanoid robots, the chip is akin to the cerebral cortex. Its performance determines the upper limit of the robot's intelligence. Relying on external suppliers (such as NVIDIA) for such a critical component may mean:

1. The computing architecture is defined by others, requiring their support to adapt to new algorithms.

2. Cost and supply cycles are constrained.

3. Algorithm optimization is limited (e.g., energy efficiency, latency, and power optimization depend on chip manufacturer support).

Additionally, XPENG has multiple products requiring chips, such as cars, aircraft, and robots. These products can share a common intelligent platform: autonomous driving for cars, real-time navigation and stable control for flying cars, and even more so for robots.

So, what technical features does XPENG's self-developed chip offer?

It primarily supports high computing power and large models. For instance, the Turing chip is equipped with a 40-core processor and claims to support large models with 30 billion parameters.

While these specifications appear impressive, their actual performance in robots and complex scenarios requires time to verify. Nonetheless, XPENG's courage and innovative spirit in developing its chip are commendable.

This article does not constitute any investment advice.