GEONT East Intelligence Unveils a New Path for High-Quality Development in Industrial AI at the 2025 China 5G+ Industrial Internet Conference

![]() 12/02 2025

12/02 2025

![]() 561

561

From November 21 to 23, the 2025 China 5G+ Industrial Internet Conference, centered around the theme "Connecting Everything, Leading with Intelligence," took place in Wuhan, Hubei Province. As the most prominent national event in China's 5G+ industrial internet domain, this year's conference expanded in scale, gathering representatives from government, industry, academia, research institutions, application sectors, and the financial industry to comprehensively showcase the latest advancements in industrial intelligent development. GEONT East Intelligence was invited for the fourth consecutive year, making a well-rounded appearance at the industrial supply-demand matching event, AI achievements exhibition area, and industrial visit activities. The event drew on-site media attention from Hubei TV, Wuhan TV, and Changjiang Daily, underscoring GEONT East Intelligence's robust industrial AI implementation capabilities and leading semiconductor smart manufacturing system. This, in turn, provided fresh impetus for China's manufacturing sector's intelligent transformation.

During the conference, Yang Li, the Marketing Director of GEONT East Intelligence, delivered a keynote speech titled "Breaking Through in Industrial AI: Accelerating New Quality Development with Practical Implementation." She highlighted that industrial AI is undergoing a revolutionary shift from "tool empowerment" to "decision support," marking a fundamental distinction between the AI era and the digital era in terms of transitioning from "how to do" to "what to do."

When discussing the key elements for successful industrial AI implementation, Yang Li emphasized that GEONT East Intelligence focuses on the ABCDE technological framework, harnessing the synergy of algorithms, big data, computing power, domain knowledge, and intelligent equipment to tackle industry pain points such as weak generalization capabilities, high trial-and-error costs, and insufficient scenario stability. In fact, GEONT East Intelligence has developed a comprehensive industrial AI product matrix, including its self-developed "Octopus Brain" Agentic AI platform, which supports data feedback loops, scenario-specific small models, and vertical domain large models. For specific business scenarios, it offers one-stop industrial AI solutions, such as the Equipment Knowledge Base Agent "Little Luban," Energy and Carbon Brain Platform, Tianshu AI Defect Detection System, and Data Intelligence Large Model Assistant. These solutions cater to needs like data exploration, root cause analysis, predictive warning, reverse control optimization, and management traceability. These innovations have facilitated manufacturing enterprises' transition from "tool empowerment" to "decision support." For instance, at TCL Huaxing, AI improved defect detection accuracy from 85% to 95%, resulting in annual savings exceeding 50 million yuan. In the semiconductor and new energy photovoltaic industries, applications like GEONT East Intelligence's AI virtual metrology, yield analysis, and large model Q&A have significantly reduced losses and labor costs, establishing a replicable and scalable intelligent upgrade path.

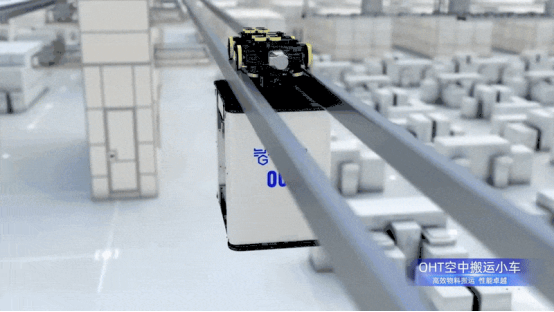

At the conference's AI achievements exhibition area, GEONT East Intelligence showcased its strategic focus on the semiconductor sector with its "AI+CIM+AMHS" integrated solution for semiconductor smart factories, combining software and hardware. The "Overhead Vehicle (OHT) Intelligent Agent" garnered significant attention from industry representatives in integrated circuits, new display technologies, and equipment manufacturing due to its autonomous optimal path calculation, dynamic response to production rhythm changes, and scheduling optimization capabilities. This demonstrated the immense demand and broad prospects for industrial AI in high-end manufacturing.

It is reported that GEONT East Intelligence is expediting the deep integration of industrial AI with hardware equipment. In core semiconductor material handling scenarios, its independently controllable AMHS solutions, represented by OHT (Overhead Vehicle) and Stocker, have secured multiple leading Chinese semiconductor clients. Building on the Phase I project of the Hong Kong University-GEONT East Intelligence Industrial Joint Laboratory, it has co-developed intelligent scheduling models, integrating MES, MCS business data, and OHTC operational data to create a highly business-aware AMHS solution. This aims to achieve breakthroughs in the core field of thousand-unit OHT scheduling algorithms.

During the media interview session, Hubei TV, Wuhan TV, and Changjiang Daily focused on GEONT East Intelligence's achievements and future strategic plans in Hubei. Yang Li stated that since establishing its headquarters in Wuhan Optics Valley in 2019, GEONT East Intelligence has provided technological transformation consulting to over 800 manufacturing enterprises in Hubei, assisting leading companies like Guide Infrared, Wuhan Xinxin, and Dongfeng Motor in building digital factory projects. Leveraging investments from Optics Valley Financial Holdings, Optics Valley Industrial Investment, and Jiaxing Nanhu Venture Capital, it completed a hundred-million-yuan Series C funding round, accelerating its ecosystem development in industrial AI, large models, and industrial software. Rooted in Hubei, GEONT East Intelligence aims to build a new digital foundation for regional new quality productivity through its three strategic systems: "AI + Industrial Software + Intelligent Equipment."

This year's conference featured a special Optics Valley 5G+ Industrial Internet Industry Visit, with the 1,200-square-meter "GEONT East Intelligence Industrial Innovation Base" located at the Wuhan Optics Valley International Exhibition Center as a key stop. The conference opened new avenues for industry collaboration and injected stronger momentum into China's manufacturing sector's high-quality development.

Looking ahead, GEONT East Intelligence will continue to leverage Wuhan as its innovation hub, industrial AI as its technological engine, and semiconductor smart manufacturing as its strategic high ground, collaborating with Hubei's manufacturing sector to advance industrial digitalization and intelligence.