【CIM Acceleration, AI-Powered Solutions】No.4|IntelliCraft Knowledge Base Agent: The "Dual-Engine" Intelligent Agent for Semiconductor Knowledge Management

![]() 12/02 2025

12/02 2025

![]() 646

646

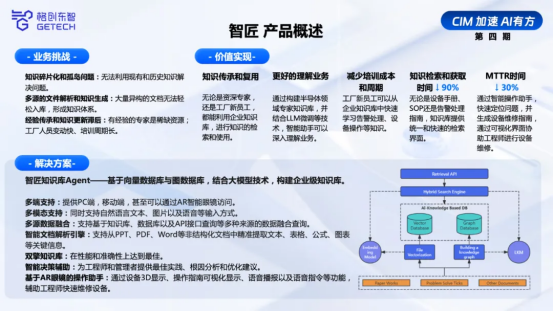

Semiconductor manufacturing, as a knowledge-intensive industry, often faces a daunting challenge: the inheritance of intangible "knowledge." A common phenomenon is that senior engineers retire, taking with them decades of equipment operation experience, while new employees are overwhelmed by stacks of equipment manuals, and solutions to critical failures are scattered across PPT reports in different departments. Knowledge, the most valuable asset for semiconductor companies, fails to fully realize its potential due to fragmentation and isolation. Knowledge silos and experience gaps are quietly affecting factory operational efficiency and innovation capabilities.

The IntelliCraft Knowledge Base Agent launched by GEGUTRON is a profound response to this core pain point. IntelliCraft is an enterprise-level knowledge management hub that integrates a "dual-engine" architecture of knowledge base, intelligent parsing, and multimodal interaction. It is committed to transforming scattered knowledge fragments into a systematic and structured knowledge system through AI technology.

Addressing Three Key Challenges: Fragmentation, Isolation, and Inheritance Difficulties

Knowledge management in semiconductor factories faces three major challenges:

Knowledge Fragmentation: Massive amounts of unstructured documents, such as equipment manuals, SOPs, fault reports, and case summaries, are scattered across departments in various formats, creating information silos.

Difficulty in Experience Inheritance: The tacit knowledge of senior experts is challenging to effectively capture, while high industry talent turnover and lengthy training cycles make "experience gaps" a common occurrence.

Inefficient Knowledge Acquisition: Engineers spend significant time manually searching for information, leading to slow fault response times and affecting continuous and stable production line operations.

"Vector + Graph" Dual-Database Driven, Doubling Accuracy in "Retrieval + Reasoning"

The core breakthrough of IntelliCraft lies in its construction of a knowledge foundation driven by a "Vector Database + Graph Database" dual-engine approach. The vector database, with its powerful semantic understanding capabilities, enables intelligent knowledge retrieval, accurately capturing intent and locating relevant information even with colloquial or incomplete queries. The graph database constructs a relational network among equipment, faults, and process parameters, providing the system with "logical reasoning" capabilities to trace problem origins and recommend associated solutions.

The synergy of the "Vector Database + Graph Database" dual engines preserves semantic-based retrieval capabilities while enhancing knowledge reasoning. When an engineer inquires about "etching chamber pressure fluctuations," the system not only provides parameter adjustment guidelines but also presents historical similar cases, key parameters affecting yield, and even recommends preventive maintenance measures, forming a closed-loop decision-making process.

Multi-Scenario Empowerment, from Equipment Maintenance to New Employee Training

The practical value of IntelliCraft is fully demonstrated across various semiconductor manufacturing scenarios.

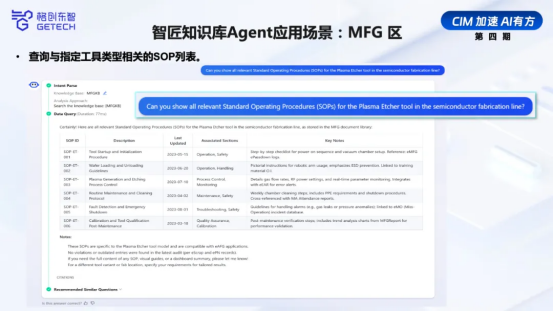

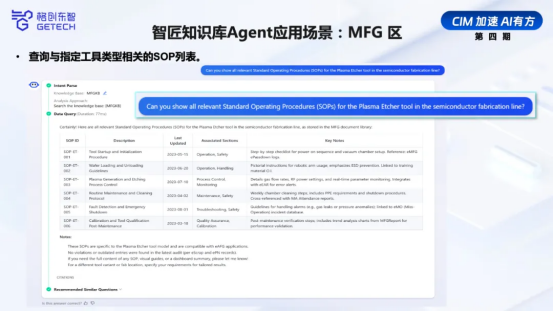

In MFG scenarios, employees can use IntelliCraft to monitor production processes, equipment status, and process parameters in real-time. By integrating multi-source heterogeneous data (e.g., SOPs, reports), it enhances production transparency and decision-making efficiency through structured analysis.

In equipment maintenance scenarios, engineers can use AR glasses to visualize equipment structures, obtain disassembly guidance via voice commands, view 3D models, and reduce mean time to repair by 30%.

In daily operations and training, employees can ask questions in natural language to quickly access SOPs and alarm handling guidelines, improving knowledge retrieval efficiency by 90% and significantly shortening the training period for new employees.

In a practical application with a semiconductor customer, IntelliCraft successfully parsed years of accumulated engineering reports, case summaries, and other documents, constructing a systematic knowledge network covering equipment knowledge, process experience, and fault handling. Engineers can now obtain precise solutions simply by asking questions in natural language, significantly improving problem-solving efficiency and demonstrating its exceptional capability in handling semiconductor expertise.

It is noteworthy that the IntelliCraft Agent does not exist in isolation but is deeply integrated into GEGUTRON's CIM AI Foundation framework. It collaborates with the Octopus AI Agent platform to build specialized agents focused on equipment knowledge management, links with GT Insights to provide process knowledge support for yield analysis, and integrates with AI FDC to offer knowledge-based insights for fault prediction and maintenance. IntelliCraft is not merely a knowledge retrieval tool but has become the "knowledge brain" of the entire intelligent manufacturing system. It proactively pushes knowledge to those who need it at the right time and in the right way, transforming from "people seeking knowledge" to "knowledge seeking people."

The implementation of GEGUTRON's IntelliCraft marks the evolution of semiconductor knowledge management from a passive "document repository" to an active "knowledge empowerment platform." In the semiconductor industry, where knowledge density determines industrial height, IntelliCraft is building a continuously appreciating and inexhaustible treasure trove of knowledge assets for enterprises.