When Robots Cease to Be Rare, System Integrators Start Competing for Listings

![]() 01/26 2026

01/26 2026

![]() 461

461

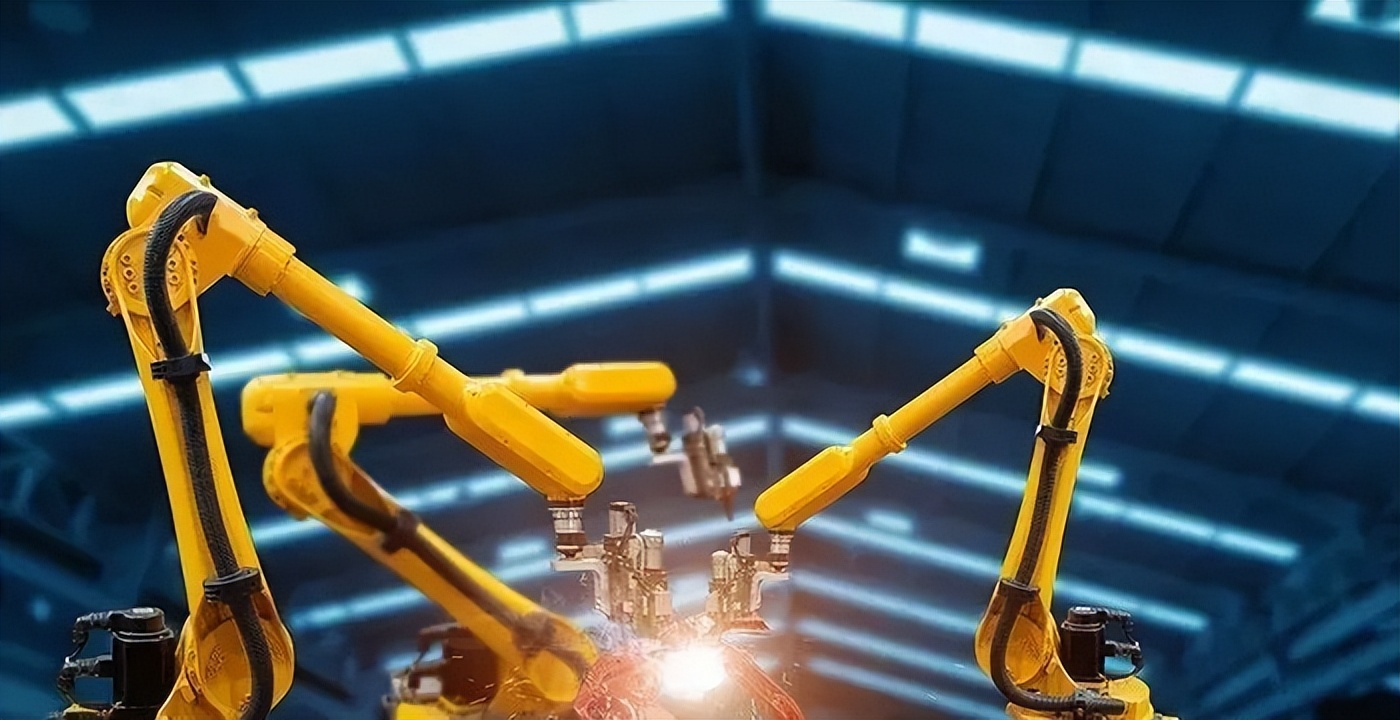

Over the past few years, industrial robots have nearly transformed into a 'panacea' for manufacturing upgrades. From Industry 4.0 to smart manufacturing, and from automotive factories to new energy production lines, almost all discussions centered on efficiency and cost reduction ultimately hinge on the phrase: 'robot penetration rate.'

However, the winds of change are subtly blowing in the capital markets.

While the technological approaches of complete machine manufacturers are frequently debated and their valuation models are constantly adjusted, another type of participant, long positioned in the middle of the industrial chain with relatively limited influence, is beginning to step into the spotlight—robot automation system integrators. Shanghai Junyi's recent submission of a listing application to the Hong Kong Stock Exchange serves as the latest indicator of this shift.

This is not merely a straightforward IPO narrative. Notably, following the high level of automation in new energy and automotive manufacturing, robot bodies are gradually being 'demystified,' and the true determinants of production stability, rhythm, and yield lie in system-level integration capabilities.

Yet, is this layer of capability a scarce asset or an overvalued engineering experience? As system integrators start to be valued by capital, the industry's contradictions and limitations are simultaneously laid bare.

From 'Robot Dividends' to 'System Anxiety': Manufacturing Redefines Its Core Value

Analyzing the progress of manufacturing automation over the past decade, a clear shift becomes apparent: the issue is no longer about possessing robots but about how to effectively utilize them.

The global market for robot automation system integration expanded from approximately 120.7 billion yuan in 2019 to 223.9 billion yuan in 2024, with a compound annual growth rate exceeding 13%. This growth is not solely driven by new factories but more by the modification, upgrading, and reconfiguration of existing production lines.

The underlying rationale is straightforward. As manufacturing processes become more extended and product iteration speeds up, efficiency gains from individual devices can no longer be linearly translated into overall line capacity.

In automotive and new energy factories, the initial areas to undergo automation were single-station, highly standardized processes. However, as automation progresses to mid- and late-stage processes, particularly those involving parallel multi-station operations and highly interconnected processes, complexity rises exponentially.

At this juncture, robot bodies cease to be the primary variable; the real challenges shift to rhythm matching, data coordination, exception handling, and future scalability. This is precisely where the value of system integrators begins to shine.

From the customer's standpoint, this shift is particularly noticeable. The objective of introducing automation in manufacturing has evolved from the initial 'labor replacement and cost reduction' to 'controlling uncertainty.'

Questions such as whether production rhythms are stable, whether yields are predictable, and whether future expansions are replicable cannot be fully addressed by single-device manufacturers. These must be tackled at the overall architectural level by system integrators.

Shanghai Junyi operates precisely in this 're-priced' intermediate zone. It does not manufacture robots but must comprehend the limitations of different brands of robots, sensors, and control systems in real-world processes. It does not directly engage with end consumers but is deeply embedded in its clients' production logic. In a sense, system integrators undertake the 'organizational work' of manufacturing systems rather than merely delivering engineering solutions.

However, this is precisely where the controversy arises.

From the traditional capital market perspective, system integration has long been perceived as 'non-standard engineering,' heavily reliant on project experience and human organization, with inherently limited scalability and profit margins. Even with revenue growth, valuations often remain constrained within the service enterprise range.

This is why, when system integrators began filing for listings en masse, the market's initial reaction was not optimism but caution: Is this value discovery or a collective attempt to cash out at the end of a cycle?

The 'Engineering Trap' of New Energy Battery PACKs Reshapes Integrators' Growth and Risks

If the system integration industry's past growth was primarily driven by mature scenarios like automotive welding, then the real catalyst propelling the industry curve upward in recent years has been the automation production lines for new energy battery modules and PACKs.

The global market for new energy battery module and PACK automation solutions surged from approximately 7.1 billion yuan in 2019 to 23.29 billion yuan in 2024, with a compound annual growth rate nearing 27%, significantly outpacing the overall automation industry. This surge is attributed to the rapid rise in NEV sales and the continuous divergence of battery technology routes.

In the module and PACK stages, process complexity far surpasses that of front-end cell manufacturing. Design trends toward higher energy density and integration have increased assembly precision, safety redundancies, and inspection requirements. The emergence of new technology routes like solid-state batteries and large cylindrical cells has necessitated frequent modifications or even complete overhauls of existing production lines.

This has generated a flood of new orders for system integrators, temporarily enhancing their revenue structures and profitability.

Shanghai Junyi's concurrent revenue and profit growth in recent years reflect this cycle. Its new energy battery module and PACK business have become a major revenue source, while niche scenarios like battery tray welding contribute new increments within its automotive business.

However, this growth model inherently carries instability.

On one hand, PACK production lines are highly customized, with lengthy project cycles and complex delivery requirements, placing extreme demands on manpower and management. On the other hand, downstream clients' capital expenditures exhibit clear cyclicality; once the industry enters an adjustment phase, order fluctuations rapidly transmit to integrators.

More importantly, as China emerges as the global hub for power battery manufacturing and process iteration, system integrators are accelerating their 'global expansion.' While this seemingly opens up larger market spaces, it introduces new variables: significant differences in safety regulations, certification systems, and delivery standards across regions make project risks substantially higher than in the domestic market.

In other words, the new energy PACK boom brings not a one-way dividend but a comprehensive test of system integration capabilities, organizational strength, and risk control.

This is the most easily overlooked aspect of system integrators' listing narratives.

Capital markets tend to focus on revenue growth curves while underestimating the structural pressures engineering firms face during expansion. As project scales enlarge, geographic reach extends, and technology routes diversify, whether past experience- and labor-efficiency-dependent models can maintain profit margins and delivery stability remains unproven.

From this perspective, Shanghai Junyi's IPO resembles an early stress test.

It represents the rising status of system integrators in the industrial chain but also exposes the inherent contradictions of this model in scalability, standardization, and cyclical resistance.

When robots are no longer scarce, what manufacturing truly competes for is not just automation levels but who can stabilize systems in complex, uncertain industrial realities.

Whether capital markets are willing to pay a long-term premium for this capability remains an open question.