2024 World AI Conference | Gechuang Dongzhi: Strengthening AI + Industrial Core Technology, Creating New Quality Productivity

![]() 07/05 2024

07/05 2024

![]() 617

617

On July 4th, the 2024 World AI Conference and the High-Level Conference on Global AI Governance opened in Shanghai. Nearly a hundred domestic and foreign academicians, top scholars, and thousands of global leaders in technology and industry gathered together to promote international exchanges and cooperation in the field of AI, focusing on key topics such as AI ethics governance, large models, data, computing power, and new industrialization. During the conference, the High-Level Conference on Global AI Governance was also held, attended by Premier Li Qiang of the State Council, important leaders of various governments, and representatives from industry, academia, and research, creating a high-level "deliberative chamber" for AI global governance.

Gechuang Dongzhi has always had sufficient technical reserves in areas such as large models, vision, and machine learning, and is an excellent representative enterprise of Chinese industrial AI. Yang Li, the Marketing Director of Gechuang Dongzhi, was invited to attend the conference and delivered a keynote speech, sharing hot topics such as industrial AI and new quality productivity, and discussing and exchanging ideas with well-known enterprises on AI demand and development.

As a strategic technology leading a new round of technological revolution and industrial transformation, AI plays an important role in promoting the digital and intelligent transformation of the manufacturing industry. Yang Li said that AI is increasingly being applied in multiple stages of manufacturing, including research, production, supply, sales, and service, especially in the production and manufacturing process, where there are already very mature applications. For example, by applying machine learning and deep learning to analyze and utilize data collected from distributed nodes, it realizes quality management, process optimization, intelligent equipment diagnosis, and more.

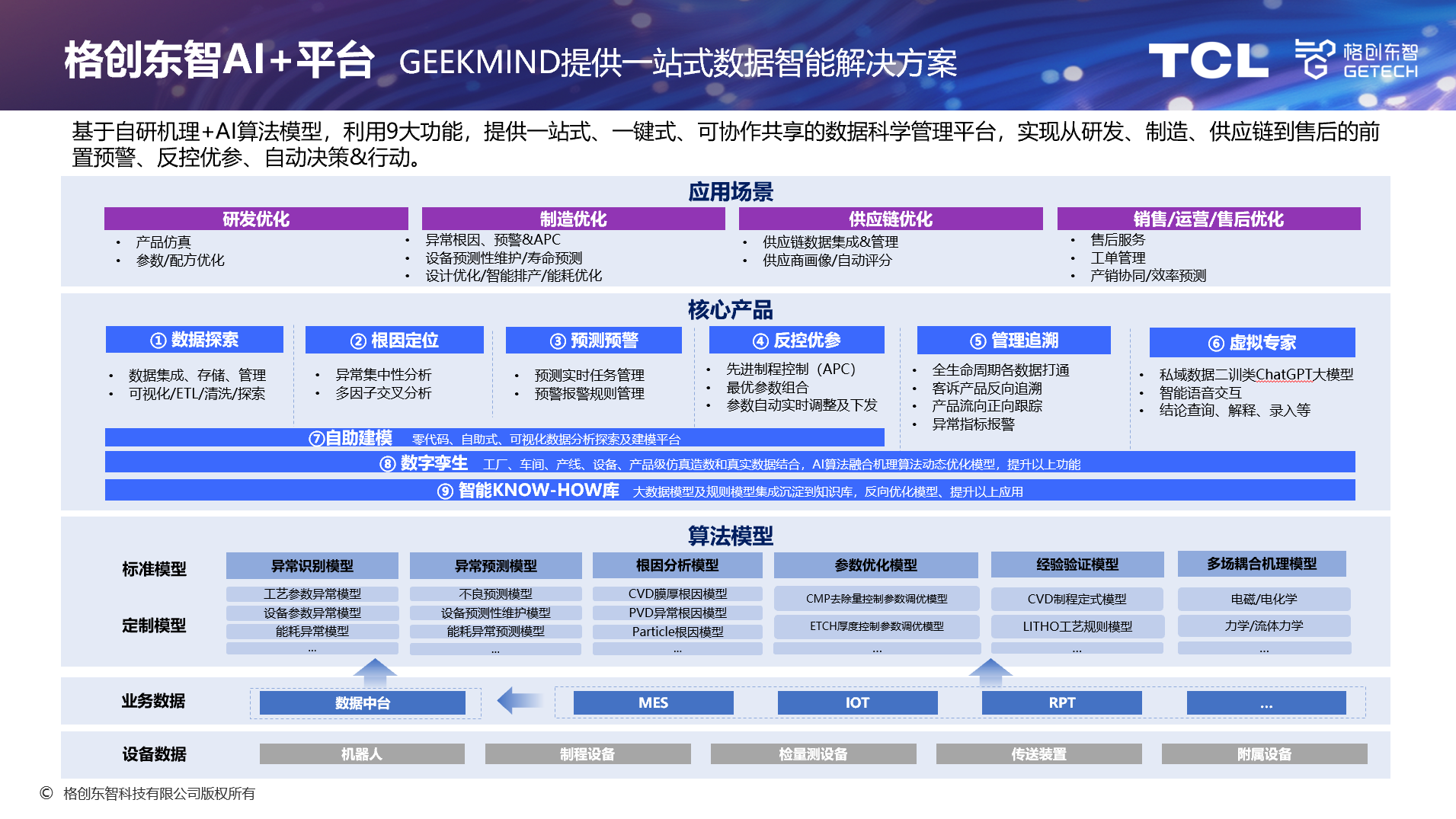

As an AI-driven industrial intelligence solution provider, Gechuang Dongzhi uses AI to reconstruct industrial operating systems. Based on core platforms such as AI, big data, and the Internet of Things, it connects to industrial sites from the bottom up and develops industrial AI applications from the top down. Through "AI in Manufacturing," it accelerates the construction of new quality productivity and provides the manufacturing industry with overall industrial intelligence solutions including planning and consulting services, solution formulation, implementation delivery, and post-maintenance operations, helping to create world-class super factories.

Yang Li pointed out that in advanced manufacturing industries such as semiconductors and new energy, more and more companies are using data intelligence technology to conduct data analysis throughout the entire production chain. By analyzing models, they can find decision-making and improvement conditions, solve inherent problems in areas such as production efficiency, stability, and yield, and continue to seek better solutions under higher quality requirements to maintain market competitiveness.

Gechuang Dongzhi's one-stop data intelligence solution is based on the AI algorithm engine platform and the large model inference engine platform, building nine major AI intelligent application functions such as yield monitoring, anomaly location, root cause analysis, predictive alerts, and reverse control optimization. It digs deeply into the data layer, providing a one-stop, one-click, collaborative, and shared data science management platform that covers all stages and scenarios of R&D, manufacturing, and after-sales. Through large data models, it achieves a high degree of intelligent production, achieving the goals of extreme cost and extreme yield.

Currently, Gechuang Dongzhi's "AI+" has achieved significant results in various industry applications. For example, at TCL Huaxing, Gechuang Dongzhi established a unified industrial intelligence platform, deeply utilizing core technologies such as large models, big data, the Internet of Things, data intelligence, and robotics to achieve digital and intelligent upgrades in key business scenarios such as R&D, production, supply chain, products, and sales, helping to create automated, digitalized, and intelligent factories. It has won honors such as being named one of the first batch of "digital leader" enterprises in the country. For example, at a certain semiconductor wafer plant, Gechuang Dongzhi provided AI services such as root cause analysis and virtual measurement for its product quality inspection process, helping customers reduce labor costs by 100,000 to 150,000 yuan per month and reduce loss costs by 12%.

Productivity innovation is the key to industrial upgrading. Gechuang Dongzhi will continue to increase R&D investment, actively promote the application of AI new quality productivity in advanced manufacturing industries such as semiconductors and new energy, promote intelligent transformation in areas such as production, quality, and energy, lead industrial intelligence innovation and upgrading, and inject continuous new momentum into high-quality development.