Humanoid Robot Ignites Interest in "PEEK Material"! Concept Stock Overview (List)

![]() 12/11 2024

12/11 2024

![]() 453

453

Recently, PEEK (Polyetheretherketone) material concept stocks have become the new darlings of the market, with stocks such as Zhongyan Shares, Xinhan New Materials, and Huitong Shares hitting the daily limit or experiencing significant gains. So what exactly is PEEK material? And what are its applications?

01. What is PEEK?

Polyetheretherketone (PEEK), a special type of high-performance polymer material.

PEEK possesses excellent comprehensive properties such as heat resistance, wear resistance, fatigue resistance, radiation resistance, peel resistance, creep resistance, flexibility, dimensional stability, impact resistance, chemical resistance, non-toxicity, and flame retardancy. Its performance is significantly superior to other engineering plastics or metal materials.

Compared to engineering plastics, PEEK materials offer both rigidity and toughness. Compared to metal materials, PEEK materials have higher specific strength while being lighter in weight, making them suitable for fields such as medical, automotive, and robotics that require lightweight materials.

In fact, as early as 1978, the UK's Imperial Chemical Industries (ICI) pioneered PEEK material, which became a strategic commodity for a considerable period afterward, with limited civilian applications. It wasn't until 1993, when ICI's PEEK business was acquired by Victrex and entered into independent operation, that PEEK material entered a stage of rapid development.

In the early stages of engineering plastics, countries like Europe and the United States invested heavily in research and development, resulting in dozens of high-performance polymers. Ultimately, less than 10 products entered large-scale application.

Recently, the PEEK material concept has garnered market attention, primarily driven by the continued surge in the concept of humanoid robots, which has fueled demand expectations for PEEK materials.

With the development of humanoid robots, there are extremely high requirements for lightweight and high-performance materials. The application of PEEK lightweight materials can effectively reduce the weight of robots while ensuring their structural strength and motion performance, making them promising for use in humanoid robot joints, skeletons, and other parts.

For example, it is speculated that Tesla's Optimus-Gen2 humanoid robot uses a significant amount of PEEK material. This potential application has sparked optimistic expectations for the demand for PEEK materials in the market, thereby boosting related concept stocks.

According to research reports by Guojin Securities, the production of 10 million humanoid robots will generate a demand for 35 billion yuan worth of PEEK materials. By 2027, domestic demand for PEEK materials is expected to exceed 16.7 billion yuan.

Everbright Securities believes that compared to general metals, PEEK materials can significantly reduce material weight while meeting the required strength, achieving lightweighting. Specifically, the tensile strength of PEEK materials is three times higher than that of aluminum alloy and twice that of steel. In terms of rigidity, the flexural modulus of elasticity of PEEK materials is four times that of aluminum alloy and 1.5 times that of steel, withstanding temperatures up to 315°C while maintaining high rigidity.

According to Sullivan's forecasts, assuming that the primary end-use products for PEEK materials in China remain unchanged, the demand for PEEK materials in China is expected to increase from 2,334 tons in 2022 to 5,079 tons in 2027, with a compound annual growth rate of approximately 16.8%. The market size is projected to grow from 1.496 billion yuan to 28.38 billion yuan, with a compound annual growth rate of about 13.7%.

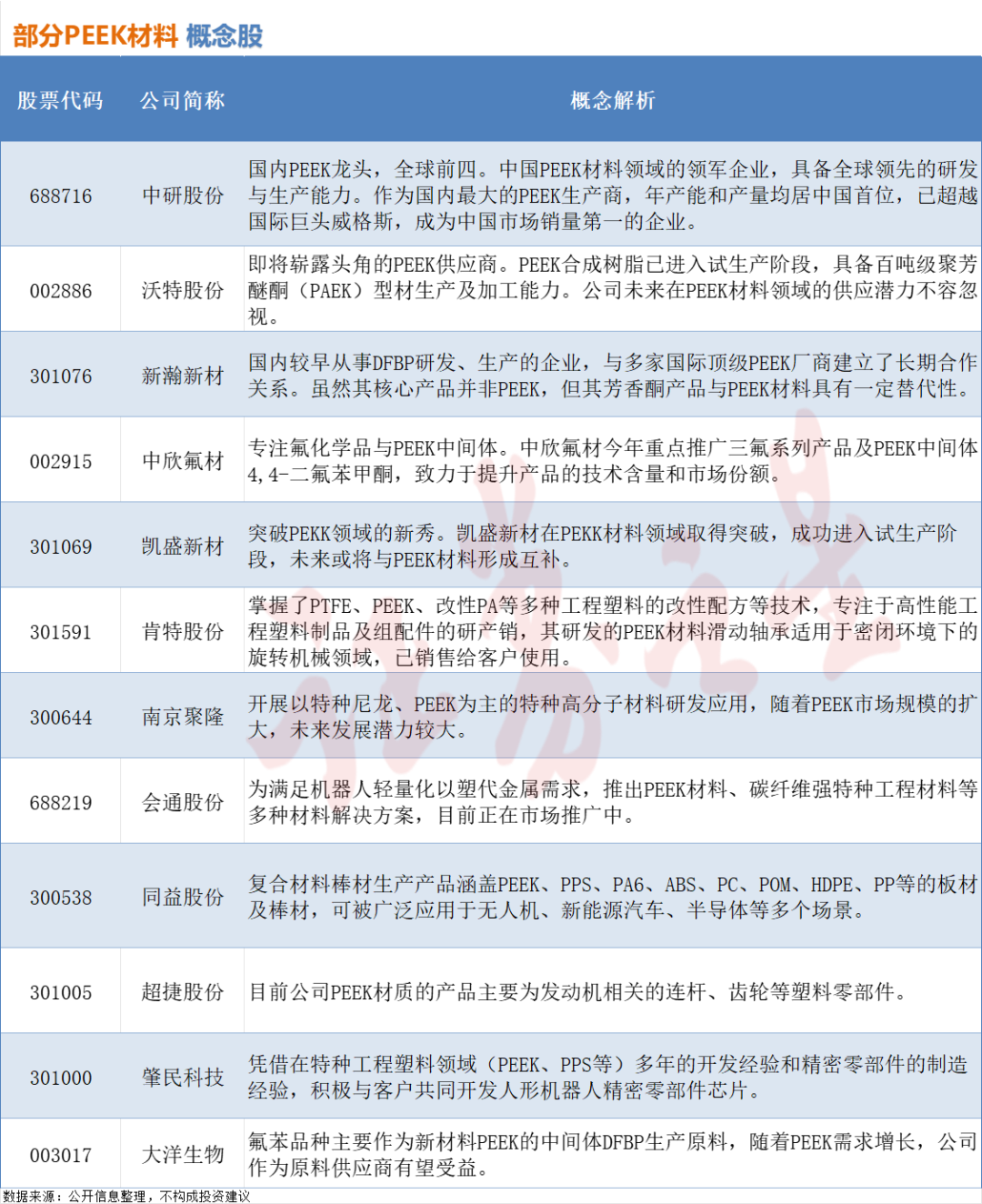

02. Overview of PEEK Concept Stocks:

The upstream raw materials for the PEEK industry primarily include Segmented fields such as difluorobenzophenone (DFBP), hydroquinone, diphenyl sulfone, and sodium phosphate, with DFBP being the most critical raw material for synthesizing PEEK. The midstream covers the intelligent manufacturing of PEEK products. As the application of PEEK materials in downstream end-use equipment is further confirmed, many A-share listed companies have also disclosed their business layouts in the PEEK material sector.

Zhongyan Shares is a leading domestic producer of PEEK materials, with a strong scale advantage in the PEEK sector. In 2021, it ranked fourth globally in PEEK sales and first in domestic market share, taking the lead in replacing international PEEK leaders like Victrex. Meanwhile, Zhongyan Shares has collaborated with multiple domestic new energy vehicle companies to jointly develop 800V motor enameled wires for new energy vehicles and continues to conduct material testing with cable manufacturers.

Fuheng New Materials revealed in its previously disclosed investor relations activity records that the company has conducted technical research on PEEK materials for some time, accumulating considerable technical achievements in this field. However, the company's current sales of PEEK products are limited, mainly concentrated in valves, piping, and other areas. The company is closely watching the popular field of humanoid robots and has focused on targeted research and development and business expansion in this area.

Watertech is one of the few domestic enterprises with independent R&D and production capabilities for PEEK materials. The company's controlled subsidiary, Zhejiang Kesai, has the capacity to produce and process hundreds of tons of polyaryletherketone (PAEK) profiles, supplying customers in precision electronics, electronic information, industrial machinery, and other fields. With the development of downstream industries such as new energy vehicles, low-altitude economy, semiconductors, AI computing power, and robotics, the company is gradually entering a period of capacity release.

Kent Shares revealed that the company has technical reserves related to carbon fiber-reinforced polyetheretherketone (CF/PEEK). Material modification refers to adding reinforcing or functional materials such as glass fiber, carbon fiber, and nanoparticles to engineering plastic raw materials to obtain high-performance, high-strength, lightweight, and highly reliable composite engineering plastics.

Guangqi Technology has technical reserves and product application capabilities for electromagnetic shielding materials and PEEK materials.