When Will Power Batteries Transition from Liquid to Solid State?

![]() 11/19 2025

11/19 2025

![]() 477

477

Introduction | Overview

Since 2025, solid-state batteries have become a focal point in both the automotive industry and capital markets. Domestic battery and vehicle manufacturers are actively developing roadmaps for the commercial mass production of solid-state batteries. However, as of now, it remains uncertain whether solid-state batteries will entirely replace traditional liquid batteries. For the foreseeable future, companies will need to explore multiple technology routes simultaneously.

This article is produced by | Heyan Yueche Studio

Written by | Zhang Chi

Edited by | He Zi

Full text: 2,859 characters

Reading time: 4 minutes

When Will Solid-State Batteries Be Ready for Mass Production in Vehicles?

Many domestic and foreign automakers, as well as power battery companies, are striving towards the mass production of solid-state batteries. On November 12, the 2025 World Power Battery Conference opened in Yibin City, Sichuan Province. At the conference, Wan Gang, President of the China Association for Science and Technology, stated that in the first three quarters of this year, China's power battery sales reached 786 GWh, with exports exceeding 129 GWh, marking year-on-year increases of 48.9% and 32.7%, respectively. As one of the most important future directions for power batteries, solid-state batteries have naturally become a focal point at the conference.

△The 2025 World Power Battery Conference recently opened in Yibin City, Sichuan Province.

Has There Been Substantial Progress in the Commercial Mass Production of Solid-State Batteries?

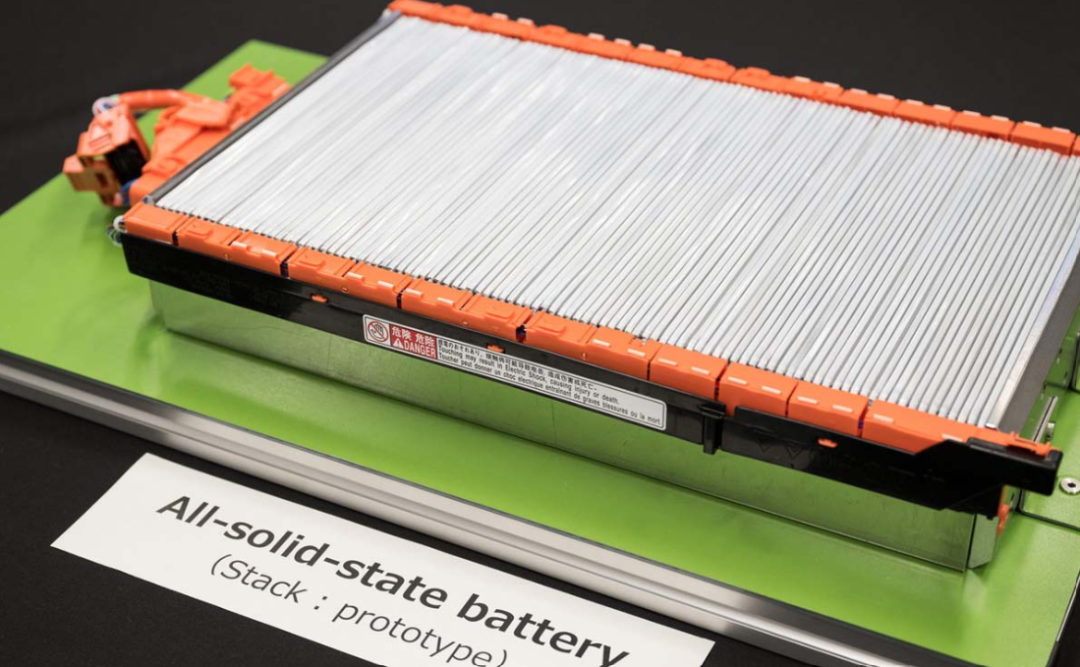

Solid-state batteries, as the name suggests, are a new type of battery technology that utilizes solid electrolytes instead of traditional liquid electrolytes. They are widely regarded as the 'ultimate solution' for power batteries. The use of solid electrolytes can significantly enhance battery energy density, alleviate user range anxiety, and address issues of short circuits and fires in power batteries.

△All-solid-state batteries offer advantages in energy density and safety over traditional liquid batteries.

Zhang Jinhua, Executive Member of the China Association for Science and Technology and President of the Society of Automotive Engineers of China, mentioned at the World Power Battery Conference that by around 2030, all-solid-state batteries are expected to complete pilot validation and small-batch vehicle installations. Vehicles equipped with all-solid-state batteries will also feature real-time battery diagnostics, safety warnings, and lifespan prediction functions. Similarly, Galaxy Securities estimates that by 2030, the global and Chinese markets for all-solid-state battery equipment could reach RMB 32.059 billion and RMB 25.136 billion, respectively.

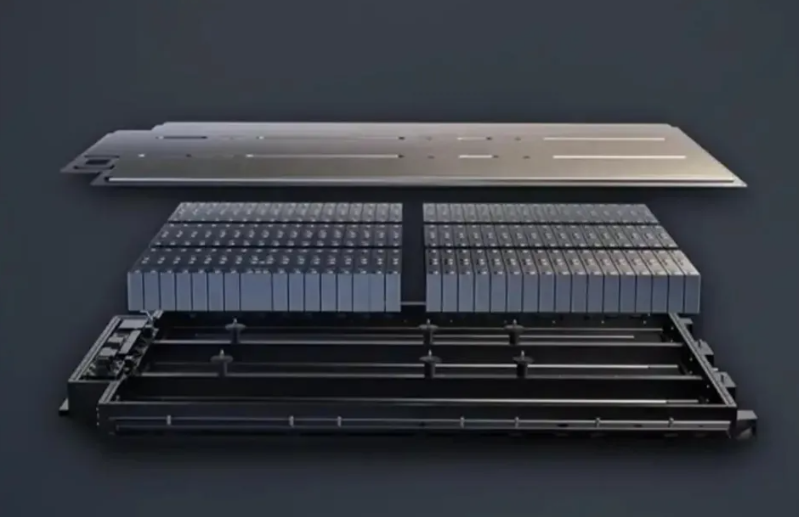

However, due to technological, cost, and commercialization constraints, solid-state batteries have been slow to achieve mass production. Specifically, in addition to technological challenges, all-solid-state batteries face persistent issues in manufacturing processes and process consistency that have not been adequately resolved. Moreover, extremely high manufacturing and material costs, along with low compatibility with traditional lithium battery production lines, pose significant obstacles to the commercial mass production of solid-state batteries. Based on currently available information, most companies' all-solid-state battery products are still in the laboratory stage, with the most advanced only reaching small-scale prototype vehicle validation. There is still a long road ahead before large-scale mass production can be achieved.

△Solid-state batteries have not yet overcome the bottlenecks for commercial mass production.

Who Is Leading the Race in Solid-State Battery Technology?

CATL is advancing its sulfide solid-state battery technology. Currently, it has completed trial production of 20Ah samples. According to the company's plan, CATL aims to achieve small-scale mass production by 2027. However, CATL has repeatedly emphasized that the true large-scale commercial mass production of its solid-state batteries is expected only after 2030.

BYD's roadmap for the mass production of solid-state batteries is also very clear: it has completed trial production of 20Ah and 60Ah all-solid-state batteries in 2024, with a battery energy density reaching 400Wh/kg. From 2025 to 2026, prototype vehicles equipped with solid-state batteries will complete vehicle durability testing and validate 5C fast charging. In 2027, BYD will initiate small-scale demonstration production, applying it to its high-end sports car models, with an initial estimated production volume of 1,000 vehicles. Between 2028 and 2030, the number of vehicle models equipped with solid-state batteries is expected to exceed 40,000, and BYD aims to achieve cost parity between solid-state and liquid batteries.

△BYD has formulated a very clear roadmap for the commercial mass production of solid-state batteries.

According to information released by GAC, its solid-state batteries have achieved an energy density of 350-400Wh/kg and a cycle life exceeding 4,000 cycles. As planned, vehicles equipped with these batteries will be launched under the Hyper (Aion) brand in 2026, making GAC one of the first automakers globally to mass-produce all-solid-state batteries.

SAIC Motor's mass production plan for solid-state batteries is undoubtedly the most aggressive. The MG4, equipped with semi-solid-state batteries, has already been launched. In 2026, solid-state batteries based on polymer-inorganic composite electrolyte technology will achieve mass production in SAIC Motor's vehicle models, with an individual mass energy density (specific energy) >400Wh/kg, a volume energy density (volumetric energy density) >820Wh/L, and a capacity exceeding 75Ah. By 2027, SAIC Motor's first all-solid-state battery, the 'Guangqi Battery,' will officially enter mass production in vehicles.

△SAIC Motor has launched the new MG4 equipped with semi-solid-state batteries.

As for Chery, it showcased the Rhino S all-solid-state battery module developed in collaboration with Guoxuan High-Tech on October 18. This battery boasts an energy density as high as 600Wh/kg, approaching the theoretical limit of lithium batteries, and can extend the driving range of electric vehicles to 1,200-1,300 kilometers. However, mass production of this battery is still some time away, with Chery planning to complete vehicle installation validation only by 2027.

XPENG Motors differs from other automakers in its approach. It plans to begin deploying solid-state batteries in 2026, not in its pure electric vehicles, but in its IRON humanoid robots.

△XPENG will be the first to deploy solid-state batteries in its IRON humanoid robots.

In addition to domestic automakers, multinational automakers are also accelerating their research and development in the field of solid-state batteries. Toyota Motor Corporation, the global automaker with the most patents for solid-state batteries, expects to launch its first mass-produced vehicle model equipped with solid-state batteries in 2027 or 2028. Nissan plans to achieve the integration of all-solid-state batteries in its next-generation pure electric vehicle models by 2028 and has already doubled the driving range. BMW, a German luxury brand, has begun testing sulfide all-solid-state batteries developed in collaboration with Solid Power on its i7 test vehicles and has initiated road tests in Munich. Mercedes-Benz, in collaboration with Factorial, has achieved a battery energy density breakthrough of over 450Wh/kg and a single-charge driving range exceeding 1,000 kilometers with its Solstice battery. For global multinational automakers, the situation where Chinese and Korean battery suppliers hold a firm grip on liquid batteries must not be repeated with solid-state batteries.

△Multinational automakers are not taking any chances with solid-state batteries.

Don't Put All Your Eggs in One Basket

At this power battery conference, in addition to the topic of solid-state batteries, several other topics were frequently mentioned.

Zeng Yuqun, Chairman of Contemporary Amperex Technology Co., Limited (CATL), shared in his report titled 'Accelerating the New Energy Industry Towards a Full-Scale Incremental Era' that CATL has already deployed a diverse range of cutting-edge battery technologies: its fifth-generation lithium iron phosphate battery products have begun mass production, surpassing mainstream industry products in both energy density and cycle life. Its ternary batteries, represented by the Qilin and Xiaoyao series, have also started large-scale applications. Sodium-ion batteries, which do not require lithium ore and offer significant cost advantages, are expected to gain popularity in new energy vehicles in high-latitude regions due to their superior low-temperature performance and more stable chemical properties.

△CATL has already deployed a diverse range of cutting-edge battery technologies.

Deng Chenghao, Head of Shenlan Auto, publicly called on the industry to pay more attention to next-generation batteries rather than solely focusing on all-solid-state batteries. He emphasized that next-generation batteries must meet three core objectives: 'safety without hidden risks, performance without shortcomings, and cost without pressure.' He also pointed out that current liquid batteries still have room for optimization and that the ultimate status of all-solid-state batteries remains to be verified. Taking Chang'an Automobile as an example, he stated that Chang'an will begin demonstration operations of all-solid-state batteries in 2027, but true mass production will only occur after 2030. In the meantime, Chang'an is also advancing the exploration of liquid battery improvements and multiple technology routes, including all-solid-state batteries, sulfides, and polyoxymethylene composites. For any automaker, the severe consequences of a failed all-solid-state battery technology route cannot be ignored.

Zeng Yuqun also mentioned in his report that in addition to new energy passenger vehicles, CATL is expanding into more usage scenarios to create a full-scale incremental market. New energy commercial vehicles, electric ships, and even electric aircraft have become CATL's 'new battlefields.' In the commercial vehicle sector, the penetration rate of new energy heavy trucks in China has reached a historic high, and CATL's Tianxing Battery has become the preferred choice for pure electric heavy trucks. In the electric ship sector, nearly 900 various pure electric ships are equipped with CATL batteries. More surprisingly, CATL is also promoting the country's first cargo ship battery swap project. In the low-altitude travel sector, a two-ton eVTOL equipped with CATL batteries has completed multiple flight validations in complex environments and is steadily progressing towards final mass production as planned.

△CATL is expanding into multiple usage scenarios for power batteries.

Commentary

For new energy vehicles, solid-state batteries are a key product that can reshape the industry landscape. Therefore, no automaker can afford to ignore this technology route. However, the difficulty of commercial mass production of solid-state batteries remains extremely high. Consequently, in the absence of sufficient evidence proving that solid-state batteries can achieve cost parity with traditional liquid batteries, automakers and mainstream battery companies will inevitably choose to pursue multiple technology routes simultaneously. Nevertheless, whoever takes a crucial step forward in the commercialization of solid-state batteries may seize the initiative in the next generation of new energy vehicles. It is expected that in another two to three years, the landscape of solid-state batteries will become clearer.

(This article is an original work by Heyan Yueche and may not be reproduced without authorization.)

Geely May Revitalize SAIC-GM Beisheng Plant to Expand Production and Regain Leadership in the Domestic Auto Market