Is AI Car Manufacturing a Pitfall?

![]() 12/02 2025

12/02 2025

![]() 616

616

Introduction

Billions invested, millions recalled. Automation is enticing, but the human element must not be overlooked.

“Discussing artificial intelligence is imperative,” as AI has now become the politically correct approach across various industries, including the automotive sector.

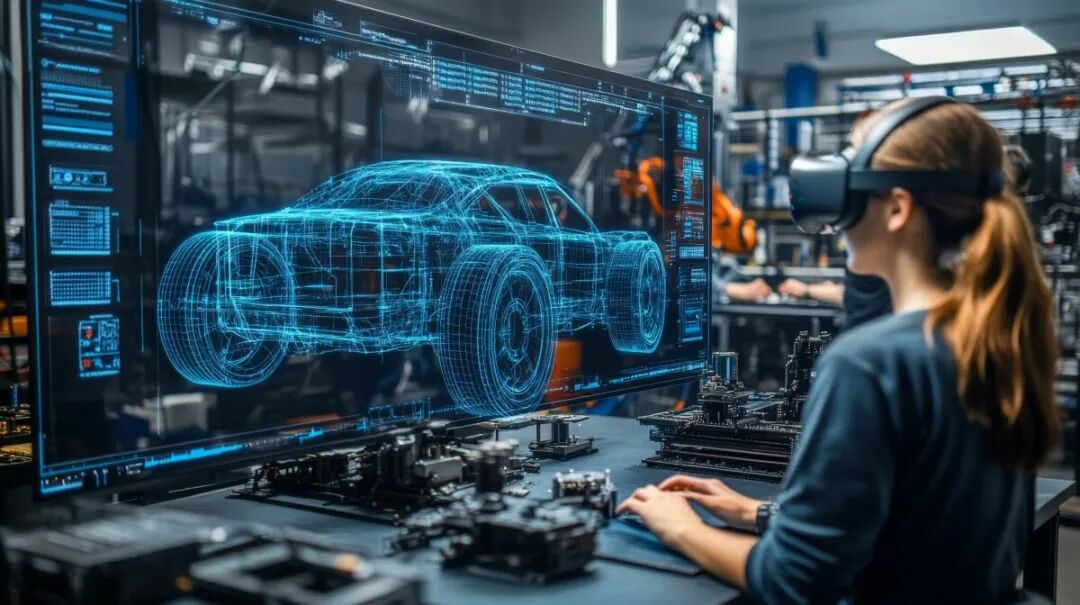

The wave of electrification and intelligence has swept through the automotive industry, driving a fervent pursuit of high automation. Whether it's high automation in the manufacturing process—black-light factories—or high automation in vehicle functions—smart cabins and intelligent driving—both have become focal points in today's industry.

The application of AI in the automotive field can be categorized into consumer-facing and production-oriented aspects. However, on both fronts, AI faces real-world challenges, sparking debates and doubts from all sides, and even harboring potential “pitfalls.”

On the consumer side, the debate over intelligent assisted driving needs no further elaboration. While a large number of tech-savvy pioneer consumers strongly support new technologies, there are still many experienced drivers who claim, “I will never trust machines or hand over the steering wheel.”

On the production side, high-precision processing and inspection involving AI intervention are seen as ways to “enhance automotive product quality and manufacturing speed.” However, based on actual conditions, companies that were early adopters of AI technology in their factories have not seen a reduction in the occurrence of faults or the number of vehicle recalls.

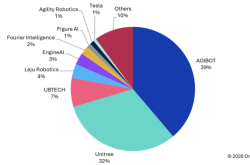

The U.S. market once again leads globally in leveraging data and experience to “blaze a trail,” with Ford and Hyundai becoming the first two automotive companies in the United States to apply AI in automobile manufacturing, each investing billions of dollars in their AI factories. It is even predictable that industry-wide investment related to AI manufacturing may reach the level of hundreds of billions of yuan.

However, the year is not yet over, and Ford has already initiated hundreds of recalls in the United States due to product faults, involving tens of millions of vehicles. Therefore, assessing the true impact of artificial intelligence on the automotive manufacturing industry still requires more time and data accumulation.

01 Billions Invested, Millions Recalled

When automotive companies spend billions of dollars (equivalent to hundreds of billions of yuan) to build AI-driven “smart factories” and promise to improve quality and reduce recalls, the actual effectiveness of this highly anticipated technology remains far from clear.

If the automation of automobile manufacturing in the previous stage was centered around mechanical concepts, then this stage is more integrated with AI concepts, where software plays a larger role.

The race to establish “black-light factories” sees no country able to compare with China. However, beyond robotic arms, “electronic eyes” and “AI brains” remain areas where overseas automotive factories can take the lead.

Ford and Hyundai are seen as the leaders in this round of the AI manufacturing competition in the U.S. automotive industry. They claim that AI systems can accurately detect defects before vehicles are delivered to customers.

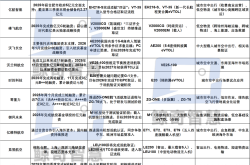

Hyundai's Metaplant factory in Georgia, built with an investment of 7.6 billion dollars, has rolled out its first batch of Ioniq 5 electric vehicles in October 2024. Hyundai has introduced Boston Dynamics robots based on AI, automatic handling vehicles, and digital twin technology here, and has expanded its cooperation with NVIDIA to continue investing in “smart factories.”

Ford's AiTriz visual system, launched in December 2024, has been deployed at 900 stations across 35 U.S. factories.

This system can verify part installation in complex situations where visibility is obstructed, making it more advanced than the initial mobile visual system introduced earlier in the year.

Ford sees AI as one of the key potential solutions to break the deadlock. Jeff Tonabene, the technical manager of Ford's Manufacturing Technology and Development Center, stated bluntly, “Our goal is to design products that cannot be installed incorrectly or pass through the production process incorrectly.”

According to Ford's statement, quality improvements have been observed in areas where the AI visual system has been deployed, and its application is being expanded. However, it is also cautiously pointed out that “not all manufacturing processes are suitable or require AI.”

Meanwhile, Hyundai spokesperson Miles Johnson elaborated on his vision, stating, “AI has enormous potential in improving quality control and early defect detection.”

But a stark reality has emerged: even with the deployment of AI technology in some factories, Ford still initiated 134 recalls in 2025, involving more than 12.17 million vehicles.

For Ford, improving quality and reducing recalls have become urgent. This veteran giant headquartered in Dearborn, Michigan, has not only set a record for recalls in the U.S. market for the entire year but may also top the annual recall list for the fourth time in five years.

02 Defects That AI Cannot Halt

When automotive companies proudly promote “AI helps improve automotive product quality,” industry observers remain cautious. Analysts believe it is still too early to evaluate the returns on these massive investments.

Judging by current performance, the effectiveness of AI intervention in factories is not ideal. The most public quality data—recall announcements—provide mixed signals.

Among vehicles produced after Ford deployed AiTriz, the average scale of recalls involving parts was far lower than the annual average. However, during the same period, Ford still initiated 22 recalls due to manufacturing defects, including issues such as improper bolt torque and poor windshield installation—defects that AI vision and torque monitoring systems are designed to detect.

Ford did not specify whether the recalled vehicles were produced at AI stations. Its spokesperson cleverly compared measuring AI through recall data to “questioning why the front door camera did not detect an intruder at the back door.”

Ultimately, Ford's record-breaking 134 recalls in 2025 affected more than 12.17 million vehicles, with warranty expenses reaching as high as 450 million dollars in the third quarter alone. Of course, Ford provided a very “face-saving” explanation—this reflects an enhanced strategy of “high caution” and “quick discovery and repair of issues.”

In comparison, Hyundai initiated 14 recalls this year, two of which involved Ioniq 5 models produced at the Georgia factory, with issues centered on headlight focus and wiring harness installation.

In principle, neither Ford nor Hyundai has provided specific data directly proving that AI improves vehicle reliability. Both automakers have unanimously positioned AI as a “long-term quality strategy” rather than an immediate solution.

Firstly, there is a “gray area” between the factors influencing AI's application in manufacturing and quality.

“It has broad prospects, but it is definitely not a panacea,” pointed out Robbie DeGraff, an analyst at AutoPacific. He believes that AI tools may help identify issues before large-scale recalls occur, but their analysis and identification capabilities may never be 100% accurate.

By the end of October, the National Highway Traffic Safety Administration recorded 817 recalls, which, although lower than the 963 recalls during the same period last year, still represent a large overall number.

Secondly, AI is still in the early stages of deployment in automotive factories, posing challenges in evaluation and data interpretation.

Measuring the impact of AI on quality has become a complex project requiring precise data and time accumulation. Adam Bernard, a former senior executive at General Motors and an industry analyst, pointed out, “‘Artificial intelligence’ is a broad concept, and the specific application determines what kind of data is needed.”

Even J.D. Power, which releases authoritative quality reports annually, stated that it does not currently track the application of AI in factories.

Therefore, we can conclude that while AI does help improve product quality in certain areas, “relying solely on books is not as good as having no books, and relying entirely on AI to improve quality may actually hinder it.” While AI embodies “advancement,” we must also be wary of avoiding “pitfalls.”

03 Both Cars and Car Manufacturing Depend on People

“Automobile manufacturers must ensure that, beyond AI, they maintain a people-oriented and robust post-production vehicle analysis and supervision system.”

This is the common conclusion reached by experts such as Robbie DeGraff, an analyst at AutoPacific, meaning that whether it is the use of automotive products on the consumer side (such as intelligent assisted driving) or the manufacturing of automobiles on the production side, the “human factor” cannot be ignored.

In the third quarter of this year, the author was invited by Lexus to visit the Lexus Miyata Factory in Miyawaka City, Fukuoka Prefecture, Kyushu, and the Tahara Factory and Test Track in Tahara Town, Wakamatsu District, Aichi Prefecture, Honshu. The content presented did not feature high automation where “humans are completely replaced.” Instead, the collaboration between precision equipment and human labor, as well as the welfare and care of personnel, took center stage.

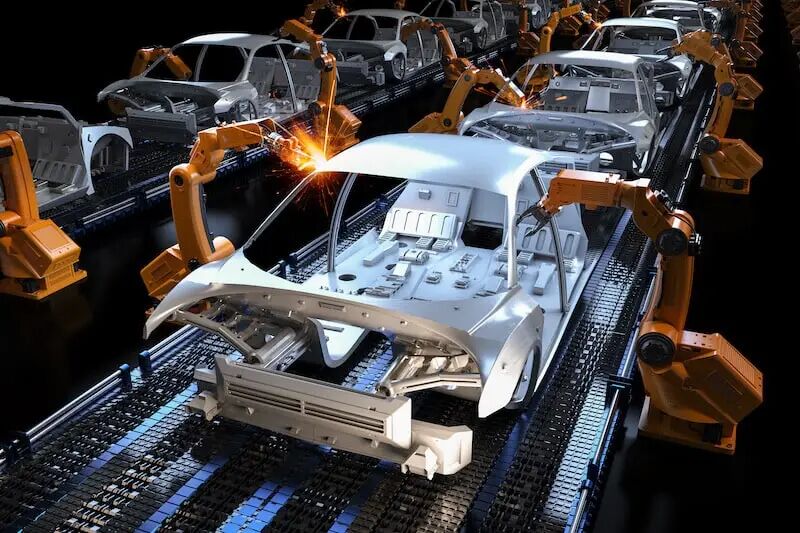

For example, on the second production line of the Miyata Factory, robotic arms are ubiquitous, and AGV trolleys operate efficiently, but workers are still seen working in an orderly manner.

Taking the installation process of the front windshield as an example, workers first clean the areas where adhesive is to be applied. Then, robots apply the “correct amount of adhesive in the correct position,” after which workers, in pairs, install the window glass onto the vehicle.

The highest-level “Takumi” (master craftsman) workers at the Lexus factory explained, “Applying the ‘correct amount of adhesive in the correct position’ is an area where robots excel. However, assembling the window glass onto the vehicle on the production line requires a sense and skill that humans excel at.”

“Even within the same work procedure, humans and machines can highly integrate and complement each other, which is the secret to achieving high quality.”

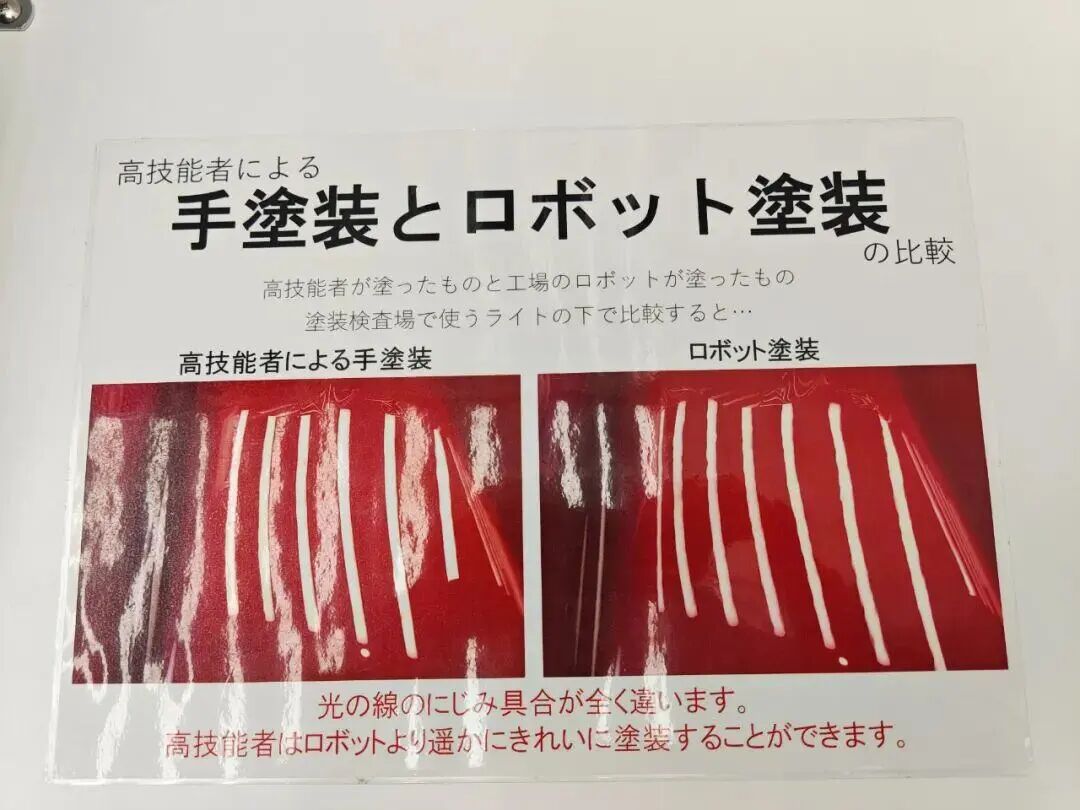

In addition, there are some areas in the painting process with complex shapes and narrow spaces where large robotic arms struggle to achieve the same level of painting as manual labor.

More importantly, the training of machines cannot be separated from manual operation. If a machine makes an operational error, manual correction is also required.

The final inspection process also involves a fusion of manual and mechanical efforts. It is said that there are 1,800 points that need to be confirmed before a vehicle leaves the factory.

Experts from both the East and the West have reached an objective consensus here.

Paul Lavoy, Vice President of Innovation and Applied Technology at the University of New Haven, reminded that while the industry is pursuing technology, it is facing severe talent challenges.

“The pace of advancement in manufacturing expertise may be faster than the speed of employee training,” he said. “This may even undermine the effectiveness of the most advanced AI systems. When implementing AI, the leadership role of humans must never be ignored. We must focus on upgrading employee skills to ensure the adoption of appropriate technologies in the right way.”

Currently, AI's journey in automobile manufacturing has just begun. Hundreds of billions of yuan have been invested, but the waters are still unsettled. Whether the promise of “zero defects” can truly be fulfilled, time and data will be the only litmus tests.

Editor-in-Chief: Shi Jie Editor: He Zengrong

THE END