ZEISS Software | Efficient Deformation Analysis to Meet Multi-Industry Needs

![]() 12/25 2024

12/25 2024

![]() 468

468

ZEISS CORRELATE stands as a formidable 3D motion and deformation analysis software, tailored to meet the rigorous demands of dynamic measurement and analysis across industries such as machinery, automotive, and aerospace. It adeptly captures object motion trajectories, analyzes deformations, and delivers precise measurement results. The software seamlessly integrates with Zeiss hardware devices (like ARAMIS, Argus, etc.) and non-Zeiss third-party devices, facilitating rapid data import and processing. With an intuitive, user-friendly interface and robust features, ZEISS CORRELATE offers users an efficient, accurate, and reliable solution.

Key Features

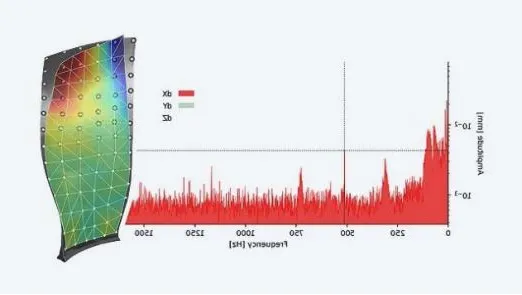

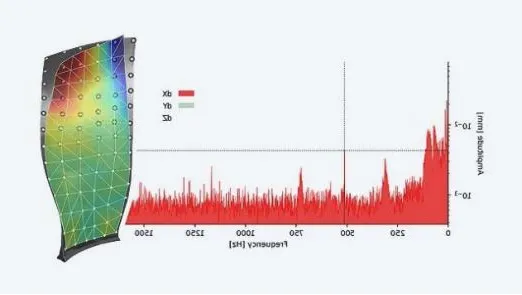

1. Dynamic Analysis

- Captures object motion trajectories and analyzes deformations in real-time.

- Supports analysis of various motion modes, including rotation and translation.

- Provides extensive visualization tools to aid intuitive understanding of analysis results.

2. Comprehensive Evaluation Functions

- Includes 6DoF analysis, trajectory analysis, virtual extensometer, and more.

- Combines scan data from motion measurements for 360-degree analysis and evaluation.

- Supports CAD and FEM import and alignment, enabling in-depth comparative analysis.

3. Efficient Report Generation

- Stores all evaluations, result variables, and correlations in the software background for quick report updates.

- Offers project templates to expedite evaluation and automate reporting.

- Supports exporting analysis results as printable documents or fully animated PDFs for easy sharing and presentation.

4. Compatibility with Multiple Data Sources

- Seamlessly interfaces with both Zeiss and non-Zeiss third-party devices.

- Supports import and export of multiple data formats, including STL, G3D, JT Open, etc.

Primary Application Scenarios

1. Aerospace Industry

In the design and manufacturing of aerospace vehicles, dynamic testing and deformation analysis of critical components are essential. ZEISS CORRELATE captures deformations under high-speed motion or extreme environments, providing data to support optimized design and enhanced reliability. By simulating and analyzing vibrations and deformations during flight, the structural safety and stability of aerospace vehicles can be assessed.

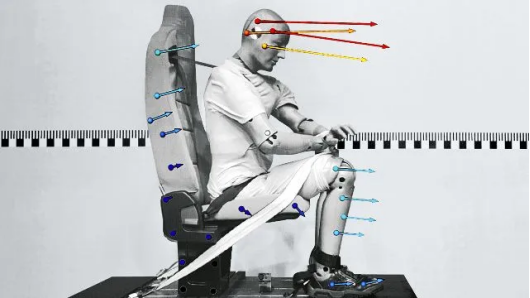

2. Automotive Manufacturing

Automotive components endure various forces during driving, including collision, acceleration, and braking. ZEISS CORRELATE performs dynamic testing and deformation analysis to assess durability and safety. During the design phase, virtual testing and validation can reduce the number and cost of physical tests.

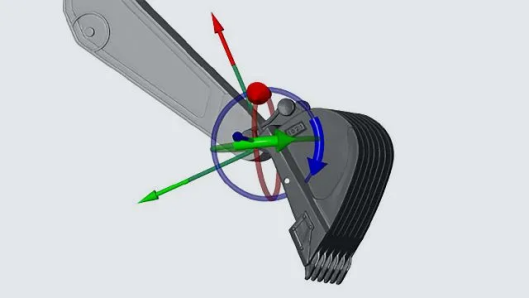

3. Machinery Manufacturing

In machinery manufacturing, the precision and stability of equipment like machine tools and cutting tools are crucial for product quality. ZEISS CORRELATE conducts dynamic performance testing and deformation analysis, helping users optimize machining processes and parameters. By analyzing vibrations and deformations, potential failure points can be identified and repaired, improving equipment reliability and lifespan.

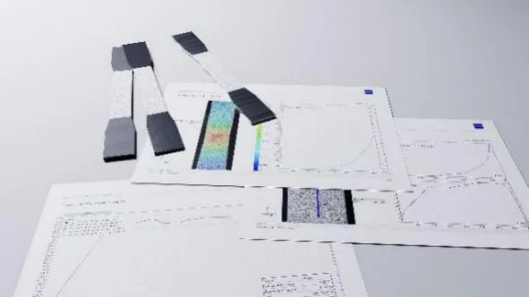

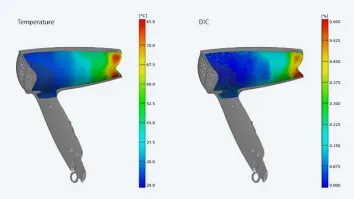

4. Electronics Manufacturing

In electronics manufacturing, precise measurement and analysis of key components like circuit boards and chips are necessary. ZEISS CORRELATE captures deformations during manufacturing to ensure product quality and reliability. By analyzing thermal deformations and mechanical stresses, design and manufacturing processes can be optimized, enhancing product performance and stability.

5. Biomedical Field

In the biomedical field, dynamic testing and deformation analysis of biological tissues and organs are vital. ZEISS CORRELATE captures deformations under physiological or pathological conditions, providing data for medical research. By analyzing deformations, the health status and disease progression can be assessed, guiding diagnosis and treatment.

6. Other Industrial Applications

In infrastructure sectors like shipping, railways, and bridges, ZEISS CORRELATE analyzes structural stability and safety. In sports equipment manufacturing, it aids in analyzing deformations and performance. In the energy sector, it helps analyze deformations and performance stability of equipment like wind turbines and solar panels.