Humanoid Robots Are Racing Towards Mass Delivery in Diverse Fields

![]() 09/03 2025

09/03 2025

![]() 679

679

Author | Mao Xinru

During this year's Double Seventh Festival, an unusual "wedding witness" made an appearance at the Marriage Registration Office in Nanshan District, Shenzhen.

It not only stamped wedding certificates for new couples, presented roses, but also participated in the theme event and took group photos as mementos. This "wedding witness" was Xingchen Intelligence's Astribot S1 humanoid robot.

It's undeniable that from elderly care and commercial services to now large-scale industrial applications, humanoid robots are accelerating their integration into all facets of our lives along the fast track of "multi-scenario implementation".

And Astribot S1, having just successfully completed its "wedding witness" mission, is about to switch roles and devote itself to the more challenging frontline of industrial production.

Today, Xingchen Intelligence announced a strategic cooperation with Xianwork Intelligence for the order of thousands of humanoid robots, aiming to promote the large-scale and phased deployment of thousands of AI robots in industrial, manufacturing, warehousing, logistics, and other scenarios within the next two years.

This cooperation is not only one of the earliest commercial collaborations involving thousands of humanoid robots in the industrial field in China this year but also provides a new practical case for the deep integration of "robot+" and intelligent manufacturing.

Xingchen Intelligence: Aiming to be the "Super Assistant" of Embodied Intelligence

In the fiercely competitive field of humanoid robots, Xingchen Intelligence has carved out a differentiated development path.

It made a "non-consensus" choice in its technical route, adopting rope-driven transmission technology as the core solution for the robot body. Currently, Xingchen Intelligence is also the first company in the industry to achieve mass production of rope-driven AI robots.

Lai Jie, the founder of Xingchen Intelligence, believes that the first principle of robot interaction with the physical world is the perception and control of "force" rather than visual positioning. This concept directly contributed to its choice of rope-driven technology.

Xingchen Intelligence's AI robot Astribot S1 uses rope-driven transmission technology to simulate the force application of human tendons, making the robot's behavior and movements closer to humans. It has inherent operational advantages such as high dynamic response, high dexterity, and high interaction safety.

Traditional motor drives often face issues such as large size, high rigidity, and insufficient safety, while rope-driven technology achieves a better balance between force control accuracy and safety through a transmission method similar to human muscles and tendons.

In industrial environments, this characteristic means that the robot can grasp fragile materials more gently, complete assembly tasks more accurately, and collaborate more safely with humans. Especially in logistics scenarios, Astribot S1 can handle turnover boxes of various shapes and weights, adapt to shelves and conveyor lines of different heights, and its flexibility is significantly better than traditional industrial robots.

At the software and intelligence level, Xingchen Intelligence has constructed a full-body VLA model architecture and adopted the "fast and slow brain" concept in model design, deeply integrating perception, language understanding, and motion control.

"Slow brain" is a composite system integrating the VLA large model with real-world data and the physical world model, operating at a frequency of 20Hz, responsible for task planning, physical reasoning, and cross-scenario meta-skill transfer;

"Fast brain" is based on rope-driven transmission and double closed-loop control technology, converting slow brain instructions into millimeter-level continuous actions at a frequency of 250Hz, achieving real-time dynamic correction through force feedback.

This architecture effectively resolves the contradiction between general semantic understanding and real-time precise control: the slow brain processes high-level goals and "thinks slowly", while the fast brain is responsible for "quick decision-making" and immediate execution and adjustment of actions.

In industrial scenarios, this mechanism allows the robot to not only understand high-level instructions such as "transport materials to production line 3" but also adjust its arm posture in real-time to adapt to minor changes in material positions and make instinctive avoidance reactions when encountering obstacles.

Additionally, the training data for its VLA model is primarily based on real robot interaction data, supplemented by simulation data and internet data. This data strategy improves the model's adaptability in real-world scenarios and reduces the Sim2Real Gap problem caused by pure simulation training.

Xingchen Intelligence's product matrix currently revolves around Astribot S1, priced at approximately 500,000 yuan, including a data collection remote operation platform, SDK development kit, etc. The product has been deployed in multiple scenarios and has gained customers including JD.com, CCTV, Shenzhen Elderly Care Homes, and Shenzhen Institute of Artificial Intelligence and Robotics.

These cross-scenario application experiences have accumulated rich data for Astribot S1, enabling it to have stronger generalization capabilities when entering industrial scenarios.

This cooperation with Xianwork Intelligence will bring a large amount of real industrial scenario data to Xingchen Intelligence, further enhancing the adaptability of the VLA model in manufacturing and logistics scenarios, forming a positive cycle of "more data → better model → better experience → more data".

Industrial Scenarios: The Optimal Solution for Commercialization at Present

As humanoid robots move from the laboratory to commercialization, industrial scenarios have almost become the common choice of all leading enterprises. This is the result of the combined effects of technological maturity, scenario adaptability, and commercial sustainability.

From Unitree Robotics, Xingdongjiayuan, Xingchen Intelligence, Kepler, to Tesla, Figure AI, Agility, domestic and foreign enterprises have chosen factories as early entry scenarios, accumulating data and refining technology through practical training.

Undoubtedly, industrial scenarios are the best "training ground" and starting point for the commercialization of humanoid robots at this stage.

The primary advantage of industrial scenarios lies in their structured environmental characteristics, which are highly compatible with the current technical capabilities of humanoid robots.

In manufacturing workshops or warehousing areas, the location of workstations, the speed of conveyor belts, the specifications of material boxes, the repeatability of operation processes, and exception handling processes are mostly predictable and standardizable.

Therefore, robots face lower uncertainty during the initial deployment phase, and engineers can debug positioning, force control, and grasping trajectories based on clear parameters, allowing the robots to reach a usable state more quickly.

In contrast, the environments of homes, retail stores, or public spaces are complex and changeable, requiring robots to have extremely high adaptability, robustness, and generalization capabilities. The time and cost required for their training and verification far exceed those of industrial scenarios.

From an economic feasibility perspective, the large-scale application of industrial scenarios provides an ideal path for robot companies to achieve a commercial closed loop.

The manufacturing industry faces multiple challenges such as rising labor costs, shortages of skilled workers, and pressure to improve production efficiency, creating a real market demand for humanoid robots.

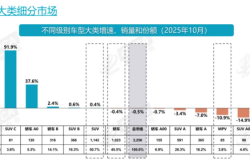

The GGII predicts that by 2030, global sales of humanoid robots will reach nearly 340,000 units, with a market size exceeding 64 billion yuan; by 2035, sales will exceed 5 million units, and the market size will exceed 400 billion yuan.

By replacing humans in tasks such as material delivery, turnover box handling, and loading and unloading, enterprises can reduce labor costs, improve production stability, and reduce safety accidents, thereby achieving quantifiable returns on investment in the short term. This commercial closed loop is difficult to achieve in consumer scenarios in the short term.

From the perspective of technological evolution, industrial scenarios are an inevitable stage for humanoid robots to transition from specialized to general-purpose.

The current humanoid robots are still far from true general intelligence. Through applications in industrial scenarios, robots can first establish technological barriers and user trust in specific fields.

Specifically in terms of application scenarios, the industrial field provides a rich task matrix for humanoid robots.

In workshops of industries such as 3C electronics and automobile manufacturing, robots can handle the transport and assembly of precision components; on new energy battery production lines, robots can perform cell inspection and handling; in logistics and warehousing scenarios, robots can handle cargo sorting, stacking, and transshipment.

In summary, industrial scenarios are considered the first stop for the commercialization of humanoid robots, stemming from the standardization and quantifiability of the scenarios themselves, as well as the practical support of industrial organizations and supply chains.

Ultimately, manufacturers that can successfully transition from industrial scenarios to households and service industries tend to be those that have made substantial progress in hardware engineering, controller coordination, and data closed loops.

The First Year of Mass Production, with Orders Flying In

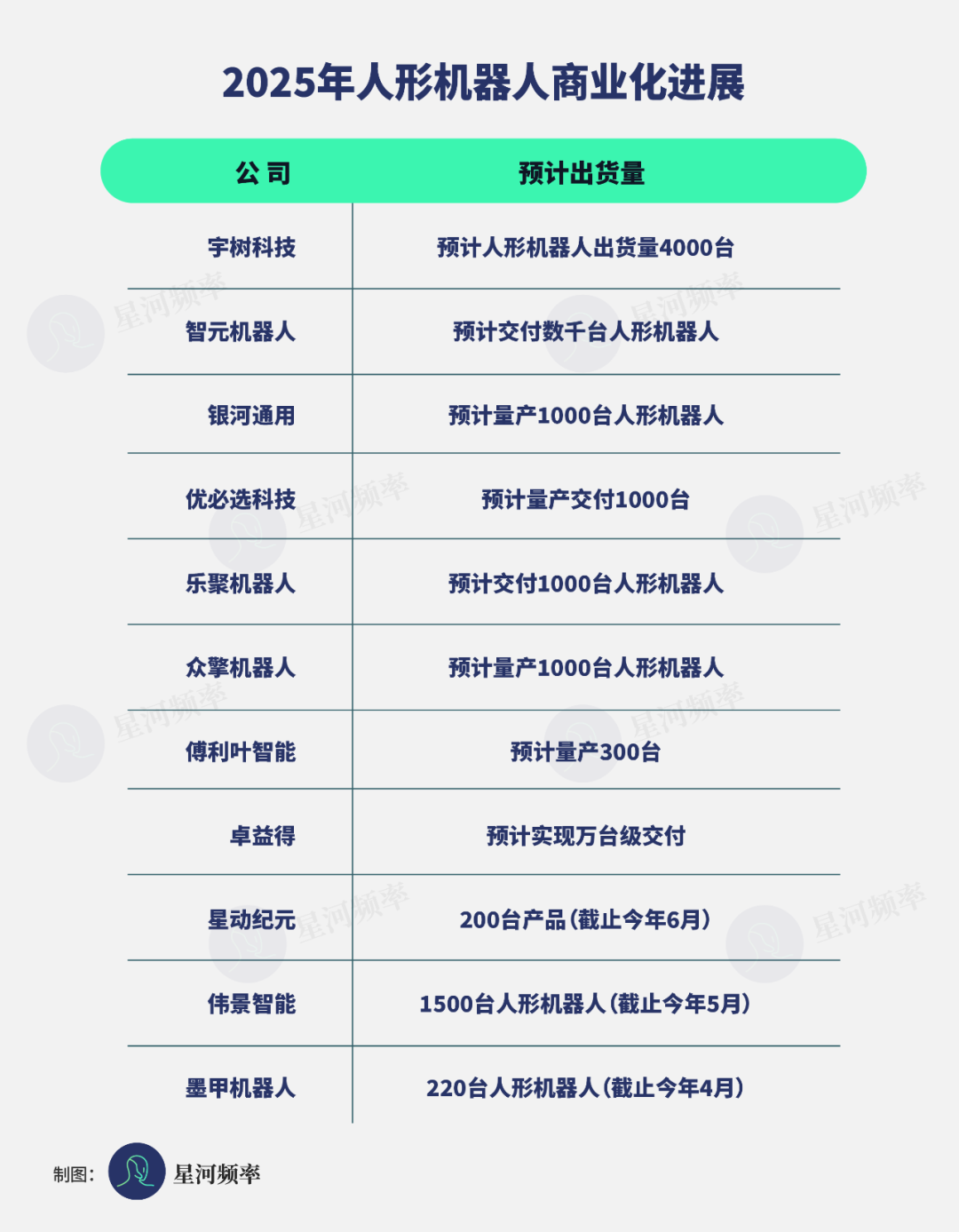

2025 is undoubtedly the first year of mass production for humanoid robots.

Data shows that sales of humanoid robots in China are expected to exceed 10,000 units this year, a year-on-year increase of 125%. At the application level, humanoid robots have been piloted in fields such as industrial manufacturing, retail distribution, and catering services, and the entire industry is entering a stage of large-scale implementation.

The leap in mass production is inseparable from leading enterprises signing large orders, driving the industry towards large-scale applications.

Starting from July this year, large orders have continued uninterrupted. First, Unitree Robotics and Zhiyuan Robotics jointly secured an order worth 124 million yuan from China Mobile, becoming the largest single procurement in the domestic humanoid robot field to date.

Subsequently, after signing a large-scale bipedal humanoid robot procurement contract in April, UBTECH won the bid for a humanoid robot procurement project worth 90.5115 million yuan from Miye Auto in July, securing the largest bid won by a global humanoid robot enterprise.

In August, Zhiyuan and Fulin Precision Industry reached a cooperation worth tens of millions of yuan, with nearly 100 Yuanzheng A2-W robots to be deployed in Fulin Precision Industry's factories, marking the first case of large-scale commercial orders for embodied robots in the domestic industrial field.

Leju Robotics became the first successful bidder for the second phase of the Beijing Humanoid Robot Data Training Center project, with an order value of 82.95 million yuan.

In addition, Tiantai Robotics signed the world's first order agreement for 10,000 embodied intelligent humanoid robots, and Mipro Intelligent also secured a humanoid robot order worth approximately 28.25 million yuan.

The significance of these orders lies not only in their size but also in the signal they collectively send: the willingness to pay and procurement processes of upstream and downstream players in the industrial chain have begun to tilt towards humanoid robots, and the market is transitioning from "demonstration tests" to a new stage of "paying for capabilities".

By dissecting these orders, we can glimpse three layers of value:

The first layer is the controllability of the supply chain and cost curve. Mass delivery requires key components to be supplied on a large scale in terms of price and quality. Without a stable supply of components, the manufacturing and maintenance costs per unit will be locked at a high level, and mass delivery will instead become a burden.

The second layer is the establishment of a commercial closed loop. Industrial customers typically focus on the "input-output ratio". When robots can achieve quantifiable improvements in clear indicators, such as yield improvement or reduction in safety incidents, they will have repurchase value, and the project may evolve into continuous procurement.

The third layer encompasses operation, maintenance, and service capabilities. Multiple deliveries necessitate a synchronized system of spare parts, an on-site engineering team, a remote diagnostic platform, and rapid iteration capabilities. Delivery marks merely the initial step, with long-term availability and maintenance cost control serving as pivotal factors in determining repurchases and expansions.

Moreover, each delivery presents an opportunity for data collection. Robots systematically gather on-site demonstrations, failure cases, and parameter tuning records, transforming them into structured samples conducive to training.

By viewing delivery as a "data-driven production process," the success of individual deliveries can be transformed into cumulative model improvements, facilitating faster adaptation in subsequent deliveries.

Conversely, if delivery remains an isolated project devoid of a data closed loop, regardless of the number of deliveries, long-term commercial value will remain fragile.

Despite the rapid surge in orders this year, the industrialization of humanoid robots continues to face challenges. Leng Xiaokun, the founder of Leju Robotics, asserts that considering only the cerebellum and body, 2025 may indeed mark the inaugural year of mass production for humanoid robots, as these robots can move, walk, and wave. However, the genuine industrialization of humanoid robots necessitates the integration of the brain, cerebellum, and body.

Leng Xiaokun's assessment underscores the underlying truth behind the current industry boom: the preliminary achievement of mass production merely addresses the "from 0 to 1" availability issue, whereas true industrial success hinges on the sustainability and versatility of "from 1 to N".

The current influx of orders signifies merely the starting gun of a prolonged marathon.

Those who will ultimately navigate cycles and progress toward a universal future are the long-term players who view each delivery as an upgrade of system capabilities and successfully convert data into genuine intelligence.