Tesla's Third-Generation Dexterous Hand: Evolution and Core Supply Chain Analysis

![]() 09/03 2025

09/03 2025

![]() 800

800

In the commercialization journey of humanoid robots, the focus of technological advancements is subtly shifting. Initially, emphasis was placed on lower limb mobility, jumping, and other motor skills, which are gradually being refined. However, the once underappreciated upper limb dexterity has now transitioned from a mere "supporting actor" to a pivotal factor determining the robot's core value, serving as the hardware cornerstone of its operational prowess.

If large models endow robots with the capacity to "think," then dexterous hands act as the "bridge" translating these thoughts into tangible actions. Without precise fingertip control capable of delicately gripping eggs and tightly screwing bolts, no matter how sophisticated the algorithm, it remains confined to the virtual realm. Furthermore, without structural robustness and sensing accuracy suited to extreme operating conditions, no matter how powerful the AI, it cannot execute practical tasks in industrial assembly or household settings.

The performance boundaries of dexterous hands directly delineate the functional upper limit of robots in the physical world. From force control precision to degree of freedom design, and from material durability to multimodal perception integration, every detailed breakthrough expands the dimensions of humanoid robots' interactions with the world.

By meticulously tracing the evolution of Tesla's three-generation dexterous hands, this article aims to provide industry practitioners with valuable insights to predict the future trajectory of dexterous hand development and formulate technology research and development, as well as commercialization strategies.

I. Tesla's First-Generation Dexterous Hand

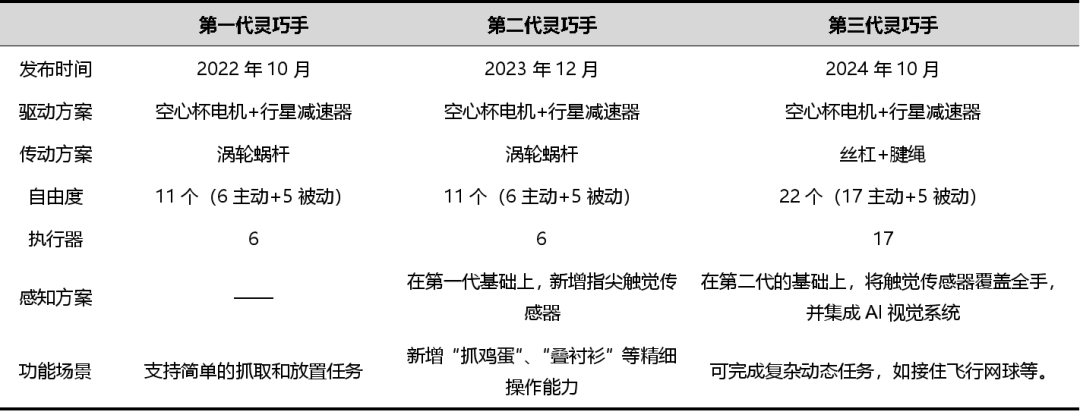

On October 1, 2022 (Beijing time), during Tesla's AI Day, Tesla unveiled the Optimus prototype humanoid robot, showcasing its first-generation dexterous hand.

Tesla Unveils Optimus Prototype

This dexterous hand adopts a biomimetic five-finger structure, featuring 11 degrees of freedom per hand. Among these, there are 6 active degrees of freedom (6 hollow cup motors integrated into the fingers, with 2 allocated to the thumb and 1 each for the other fingers). Each hand can support a maximum load of 9 kilograms, enabling simple grasping and placing tasks. Additionally, it employs a reverse self-locking design, allowing the fingers to maintain a grip even when power is off, thereby enhancing the practicality and reliability of the dexterous hand.

Parameters and Performance of the First-Generation Dexterous Hand

In terms of transmission design, this dexterous hand utilizes a worm gear transmission mechanism, which offers several advantages: it possesses self-locking capability, maintaining the grasping state when power is off; it boasts a high transmission ratio, providing a large output torque and strong grasping force; it is particularly suited for scenarios with limited space, intersecting axes, and a high reduction ratio requirement.

However, this transmission method also has its drawbacks: on one hand, the self-locking feature restricts lateral swing freedom, impacting the ability to perform high-precision grasping operations; on the other hand, the primary friction between the worm and worm gear tooth surfaces is sliding friction, resulting in relatively low transmission efficiency, easy wear, and a shorter lifespan.

II. Tesla's Second-Generation Dexterous Hand

On December 13, 2023, Tesla CEO Elon Musk first unveiled the second-generation Optimus (Optimus Gen2) online via the social media platform X (formerly Twitter).

Concurrently, Tesla's dexterous hand also underwent an upgrade, introducing the second-generation product. While maintaining the same degrees of freedom as before, this dexterous hand underwent targeted optimizations in its overall design. Critically, tactile sensors were added, equipping each finger's fingertip with tactile perception sensors.

With these enhancements, the second-generation dexterous hand can perform high-precision tasks such as pinching eggs and grasping small objects, further expanding the robot's application scenarios.

Second-Generation Dexterous Hand with New Tactile Sensors

III. Tesla's Third-Generation Dexterous Hand

On October 11, 2024, Tesla publicly unveiled the third-generation dexterous hand model for the first time at the "We, Robot" conference. It is understood that, compared to the previous two generations, this dexterous hand underwent significant upgrades, with the motors relocated to the arm, increasing the overall degrees of freedom to 22, and adopting a combined transmission scheme of lead screws and tendon ropes.

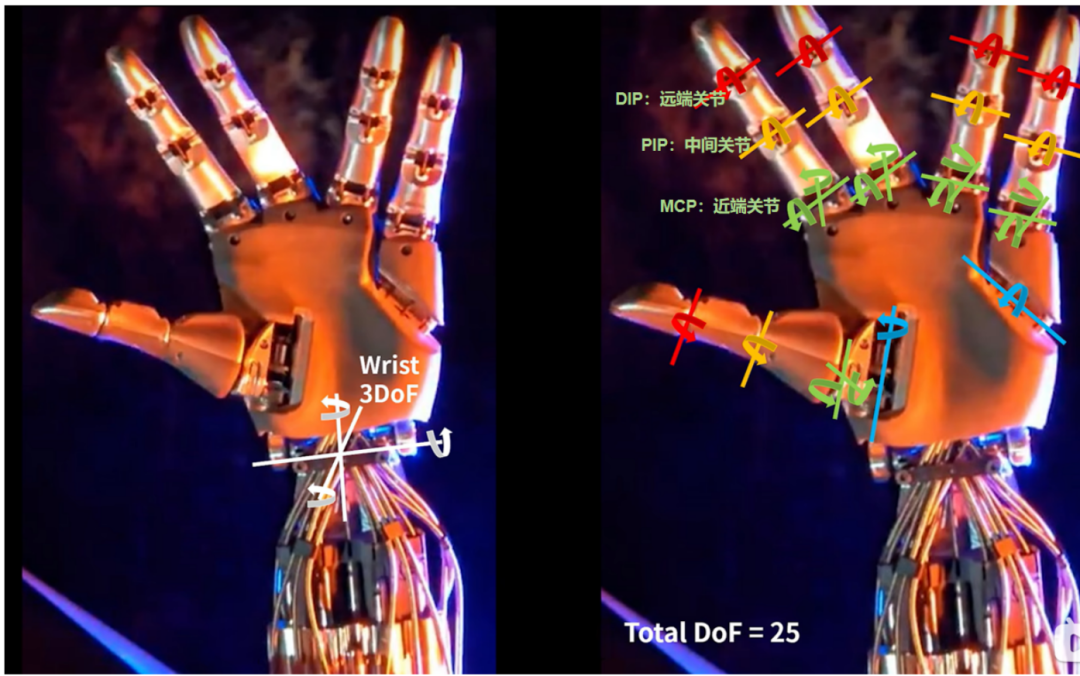

Distribution Diagram of Degrees of Freedom in the Third-Generation Dexterous Hand

Regarding the specific allocation of the 22 degrees of freedom in the dexterous hand, Tesla has yet to make an official disclosure, leading to significant disagreements and a lack of unified conclusions among industry insiders and online interpretations.

Among various theories, the author believes a relatively plausible one is: the thumb and little finger each have 5 degrees of freedom, while the other three fingers each have 4 degrees of freedom, totaling 22 degrees of freedom. Among these, there are 17 active degrees of freedom, meaning 17 motors are integrated into the forearm to control finger movement – the thumb and little finger are driven by 4 motors each, and the other 3 fingers are driven by 3 motors each. The distal interphalangeal (DIP) and proximal interphalangeal (PIP) joints of each finger are coupled and controlled by a tendon rope, representing passive degrees of freedom.

Furthermore, the wrist of this dexterous hand also has 3 degrees of freedom, or in other words, there are 3 motors controlling the wrist also integrated into the forearm.

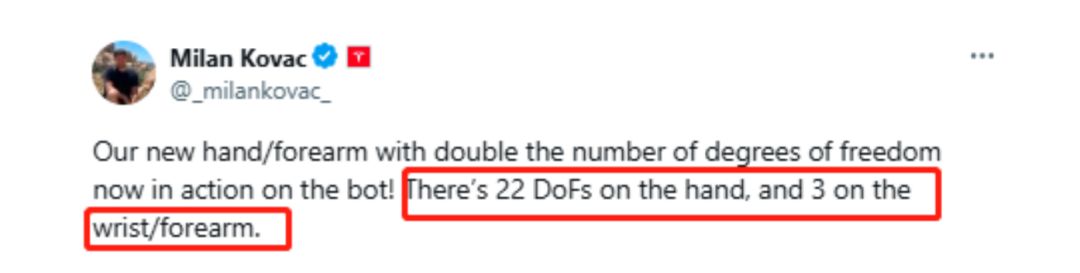

Milan Kovac, Tesla's former Vice President of the Optimus project, revealed information about the degrees of freedom of the third-generation dexterous hand on his social media account: 22 hand degrees of freedom + 3 wrist degrees of freedom.

Overall, compared to the second-generation dexterous hand, the third-generation dexterous hand exhibits the following main changes:

(1) Degrees of Freedom: The dexterous hand's degrees of freedom have increased from 11 to 22 per hand, and the active degrees of freedom have risen from 6 to 17.

(2) Drive System: The motors within the palm have been moved to the forearm, transitioning from an internal to an external configuration. The hand space is no longer constrained by motors, which not only facilitates the achievement of a high degree of freedom design but also aids in reducing maintenance and repair costs.

Moreover, by relocating the motor drive unit to the forearm and freeing up the palm's volume limit, Tesla has reportedly replaced some hollow cup motors with lower-cost brushless slotted motors, according to industry insiders.

(3) Transmission System: A hybrid transmission scheme combining planetary gearboxes, lead screws, and tendon ropes is employed.

Lead screws replace worm gears: Both convert rotational motion into linear motion, but lead screws excel in precision, load capacity, and transmission efficiency.

Tendon ropes replace torsion springs: Compared to the second-generation dexterous hand, which relied on torsion spring recovery for finger extension, the third-generation dexterous hand utilizes tendon ropes to drive finger extension, further enhancing finger flexibility.

(4) Sensor System: The tactile sensor coverage has been expanded, and a broader range of sensors has been integrated. It is reported that the tactile sensors of the third-generation dexterous hand achieve full coverage of fingers and palms, enabling more comprehensive external environment perception. Tactile perception may be upgraded to a visuo-tactile perception solution. Additionally, other multimodal perceptions such as six-axis force sensors and temperature sensors are incorporated, enabling more precise perception of object surface textures, shapes, and forces, thereby facilitating delicate dynamic grasping and complex operational tasks.

IV. Tesla's Core Supply Chain for Dexterous Hands (Domestic)

1. Drive Module

1) Motion Control

Founded in 1994 and headquartered in Shanghai, Motion Control specializes in the research and production of control motors and drive systems. It is a globally leading provider of motion control solutions. Its control motors encompass various types such as stepper motors, servo motors, DC brushless motors, and hollow cup motors, which are widely utilized in industrial automation, robotics, medical equipment, and other fields.

It is reported that since 2023, Motion Control's hollow cup motors have been continuously sampled by Tesla, and its core product, the 10mm brushless hollow cup motor (e.g., ECH10032 series), has successfully passed multiple rounds of testing for Tesla's Optimus dexterous hand.

In 2024, Motion Control completed the B-round test (3000-hour reliability verification). As of now, Motion Control has passed Tesla's C-round certification and emerged as a prospective supplier of Tesla's hollow cup motors, pending official confirmation from both parties. It is anticipated that large-scale supply will commence in Q1 2026, coinciding with the mass production of Optimus.

2) Micro-Mo

Founded in 2001 and headquartered in Shenzhen, Micro-Mo is a provider of solutions for micro-transmission and micro-drive systems, integrating design, research and development, and manufacturing. Its products are primarily used in automobiles, intelligent robots, industrial equipment, smart homes, 3C electronics, and numerous other fields. Its offerings in the robotics domain include dexterous hand components and motor drive modules.

In March 2024, Tesla's engineering team's final stop on its audit tour of Chinese factories was Micro-Mo, focusing on its precision manufacturing capabilities for micro-transmission systems. In April of the same year, Micro-Mo sampled an integrated transmission module comprising a hollow cup motor + gearbox to Tesla's North American R&D center.

By the end of May 2025, Micro-Mo had completed the development and sampling of its third-generation technical solution (brushless slotted motor + micro lead screw). This solution achieves cogging torque self-locking through stator splicing technology, and the module volume is optimized compared to the previous generation, catering to the miniaturization needs of Tesla Optimus Gen3 finger joints. Currently, this solution has entered the Tesla supply chain audit phase.

It is understood that Micro-Mo has been listed as a core supplier of Tesla's dexterous hand drive modules, alongside manufacturers such as Tuopu and Sanhua, and is also in contact with enterprises like Figure AI (supplying Figure AI with dexterous hand motor modules).

3) Dingzhi Technology

Founded in 2008 and headquartered in Changzhou, Jiangsu, Dingzhi Technology positions itself as a provider of customized precision motion control solutions. The company's main products include linear actuators, hollow cup motors, ball screws, planetary roller screws, harmonic reducers, and other key products, which are widely used in high-end fields such as medical diagnostic equipment, semiconductor manufacturing, laboratory automation, and humanoid robots.

It is reported that Dingzhi Technology's 8mm brushed hollow cup motor and 10mm brushless hollow cup motor have been sampled for Tesla's Optimus project, with products suitable for the precise drive requirements of dexterous hand joints.

However, this collaboration is indirect, facilitated through Tesla's Tier 1 supplier, Tuopu Group. Dingzhi Technology and Tuopu Group jointly develop harmonic reducers and hollow cup motor modules. The latter, as the exclusive supplier of Tesla's rotating joint assembly, integrates Dingzhi Technology's motors into the actuator assembly before supplying to Tesla.

In terms of mass production support capabilities, Dingzhi Technology has established fully automatic winding equipment for hollow cup motors, achieving self-research of core processes. The Changzhou base's annual production line of 500,000 actuators commenced operations in 2025, and the Thai factory has a planned annual production capacity of 1 million units, expected to commence production in Q3 2025.

Currently, its hollow cup motors have completed the B-round test through the Tuopu Group channel and entered Tesla's supply chain certification process. It is anticipated that small-batch verification will commence in Q4 2025. If progress remains smooth, it can support mass production and matching with Optimus Gen3 in 2026.

2. Transmission Module

1) Xinjian Transmission

Founded in 1999 and headquartered in Hangzhou, Zhejiang Province, with a research and development center in Shanghai and overseas production bases and sales networks, Xinjian Transmission has established a global operation pattern covering core markets.

Positioning itself as a "provider of intelligent transmission solutions," the company focuses on providing core transmission technology support for high-end equipment fields. Its main products encompass two systems: precision transmission components and intelligent drive modules. Core products include planetary roller screws, rotary electric drive joints, small-modulus worm gears, precision shafts, and intelligent flexible modular joints.

According to current public information, Hangzhou Xinjian Transmission is one of the key suppliers of micro lead screws for Tesla's humanoid robot dexterous hands. Its products excel in load capacity and lifespan. Currently, Xinjian Transmission is progressing through the Tesla supply chain certification process, and it is expected to form large-scale production capacity by the end of 2025.

2) Sanhua Intelligent Controls

Established in 1984 and headquartered in Shaoxing, Zhejiang Province, Sanhua Intelligent Controls boasts R&D and production facilities spanning North America, Europe, Southeast Asia, and beyond, fostering a global operational network that encompasses key markets.

Sanhua Intelligent Controls' dual-core business encompasses "refrigeration and air-conditioning electrical components" alongside "automotive components," while the company also proactively ventures into strategic emerging areas such as robotics and energy storage.

In the realm of robotics, it is noteworthy that in October 2024, Sanhua Intelligent Controls revealed during investor relations activities that its Mexican plant intends to manufacture 500,000 actuators annually, with mass production slated for the third quarter of 2025. Each actuator assembly carries a value of 5,000-8,000 yuan, aligning with the mass production demands of Tesla's Optimus Gen3.

As a Tier 1 supplier for Tesla's Optimus actuator assembly, Sanhua Intelligent Controls is tasked with the holistic design and integrated development of the rotating joint module. Meanwhile, as a Tier 2 supplier, Green Harmonic furnishes micro harmonic reducers (such as the model LHD-8002H) to Sanhua Intelligent Controls, which subsequently integrates them into the actuator assembly before delivery to Tesla. In 2023, the two entities established a joint venture factory in Mexico (controlled by Green Harmonic), planning an annual production capacity of 500,000 harmonic reducers to guarantee a steady supply to Tesla's North American facility.

3) Zhejiang Rongtai

Founded in 1998 and officially completing its shareholding system reform in 2003, Zhejiang Rongtai is headquartered in Jiaxing, Zhejiang Province. The company's primary products encompass two major segments: high-temperature-resistant insulating mica materials and precision transmission components. Its mica rigid materials, flexible materials, thermal management safety components, and other offerings provide essential insulation solutions for renowned automakers including Tesla, Volkswagen, and Volvo.

In the strategic emerging sector, Zhejiang Rongtai acquired a 51% stake in Shanghai Dizi Precision in 2025, swiftly entering the realm of precision transmission for robots, with a focus on core products such as micro ball screws and planetary roller screws.

Shanghai Dizi Precision has been deeply entrenched in the field of precision transmission for 17 years, boasting precision machining capabilities for micro ball screws of 3mm and smaller. Starting from the fourth quarter of 2024, its micro ball screws (diameter 3-5mm) were dispatched in batches for sampling to Tesla's Optimus dexterous hand, undergoing tests that encompassed extreme operating conditions like load cycles (100,000 times) and temperature shock (-40°C to 125°C).

Q1 2025 test data revealed that screw wear was contained within 0.0015mm, with a dynamic response time of less than 3ms, and the performance indicators met Tesla's technical specifications. In March 2025, Zhejiang Rongtai indirectly inked a small-batch supply agreement with Tesla through Shanghai Dizi Precision (ASP market estimates at approximately USD 300 per unit).

In terms of production capacity, Dizi Precision's Changzhou base has established a fully automated production line for micro screws, achieving a weekly capacity of approximately 3,000 units in Q2 2025, resulting in a cumulative delivery of roughly 10,000 units in the second quarter. The Thai base commenced equipment installation in Q3 2025, with plans to initiate production in Q1 2026. The initial weekly capacity target is set at 15,000 units, with a long-term objective of 30,000 to 40,000 units, to ensure localized supply to Tesla's North American factories.

Note: The content of this article is based on the collation and integration of publicly available information and is intended solely for research and exchange purposes. It does not constitute any form of investment advice. Please refrain from using it as the basis for investment decisions. Should there be any omissions, deviations, or details requiring supplementation, readers are encouraged to offer improvement suggestions and corrections.