Who Claims It's Low on Tech? Extended-Range Vehicles Can Be Impressive Too!

![]() 01/30 2026

01/30 2026

![]() 419

419

Among the plethora of new energy vehicles available, extended-range electric vehicles (EREVs) have often found themselves at the lower end of the technological respect scale, primarily due to their straightforward series system. Yet, for leading new automotive forces that prioritize intelligence, extended-range technology emerges as the most efficient solution to meet immediate demands. Furthermore, with the continuous integration of cutting-edge technologies, numerous EREVs are significantly boosting their economic efficiency and dynamic performance through innovative applications.

●800V High-Voltage Extended-Range Platform

▲Technical Highlights: IM LS9, Hyper HL, XPENG G7

Over the past two years, major automakers have begun incorporating 800V high-voltage electrical systems into their new energy vehicles. Presently, most high-end electric vehicles have adopted this system, which offers superior efficiency and is gradually gaining popularity among EREVs and plug-in hybrid vehicles.

Take SAIC IM's 'Stellar' super extended-range system as an illustration. This system utilizes a full-domain 800V high-voltage electrical setup, featuring a maximum capacity of 66kWh XiaoYao MAX battery pack, front and rear permanent magnet synchronous motors with a combined power output of 390kW, and an SiC silicon carbide electronic control unit. Despite weighing nearly 2.7 tons, it can achieve over 400km of pure electric range and a combined range of 1500km.

From a user's perspective, EREVs equipped with an 800V platform not only double their pure electric range, typically exceeding 300km—sufficient for daily commuting needs—but also support 3C or higher-level fast charging with large-capacity lithium batteries. The peak power can surpass 200kW, offering nearly full-scenario pure electric coverage in both urban and highway driving, except for long-distance self-driving trips to remote areas like 'Qinghai-Tibet-Xinjiang'.

●Active Noise Control for Range Extenders

▲Representative Models: SERES M7, Hyper A800, Avatr 06

Traditional EREVs often experience a notable increase in noise and vibration when the engine kicks in for power generation, significantly detracting from the user's travel experience. Especially for high-end vehicles costing tens of thousands of dollars, effectively isolating and reducing noise from the range extender is a crucial aspect to consider.

In addition to passive isolation solutions like sound insulation cotton and hydraulic bushings, many automakers have started optimizing the engine's starting noise itself. Take Avatr 06 as an example; its 1.5T range extender employs an electronic oil pump, ensuring maximum lubrication of various components even during the starting phase, thereby reducing high-frequency noise during the warm-up phase.

Moreover, numerous automakers' range extenders have adopted engine positioning cylinder deactivation systems. These systems halt the four pistons at the optimal phase each time the engine shuts down, maximizing the optimization of the entire machine's vibration during the next ignition start, thus achieving a truly imperceptible start.

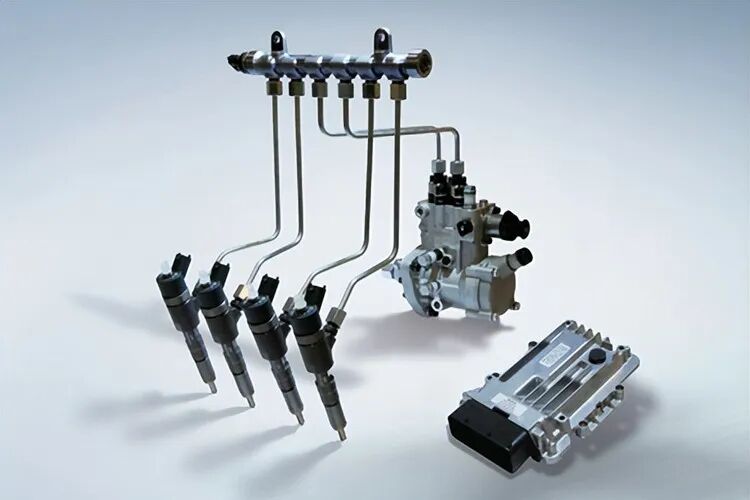

●500Bar Direct Injection Range Extender

▲Representative Models: Shenlan S09, Avatr 06

At the engine fuel supply level, most gasoline or plug-in hybrid vehicles currently utilize direct injection systems with injection pressures ranging from 200-350Bar. However, Changan Automobile has begun to popularize 500Bar in-cylinder direct injection systems across its entire range of 1.5T engines, including those used in Qiyuan, Shenlan, and Avatr EREVs.

Take the 1.5T range extender used in Shenlan S09 as an example. This engine features a long-stroke design of 1.45:1 and incorporates a 500Bar common rail direct injection system. The fuel injection particle size is refined to 6.3 microns, enabling more thorough fuel atomization. This not only results in more complete combustion and an overall fuel-to-electricity conversion efficiency of 3.7kWh/L but also effectively reduces harmful emissions of nitrogen oxides.

●Direct-Drive Range Extender

▲Representative Model: Leapmotor D19

The conventional extended-range system treats the engine located at the front axle as a gasoline engine without a dedicated power transmission path to the vehicle. This can be seen as the most fundamental difference between EREVs and plug-in hybrid vehicles.

Interestingly, Leapmotor has implemented a dual-energy motor four-wheel-drive extended-range system in its first full-size SUV, the D19. The primary driving force for the vehicle still originates from the permanent magnet synchronous motor located at the rear axle. However, the engine and motor combination at the front axle can not only generate electricity but also, under specific conditions, decouple the engine from the front axle motor, allowing the motor to directly drive the front wheels through a reducer.

Unlike plug-in hybrid vehicles with direct engine drive, this extended-range solution also assigns the motor the dual tasks of driving and generating electricity. Nevertheless, its engine still solely generates electricity and cannot directly drive the wheels. Moreover, since there is only one motor at the front wheels, this means that four-wheel drive is not feasible in extended-range mode (when the motor needs to generate electricity). Perhaps considering this limitation, the vehicle directly utilizes a lithium battery pack with a capacity of up to 80.3kWh, achieving a pure electric range of up to 500km, which is even more impressive than many pure electric vehicles, truly treating the extended-range mode as an emergency backup.

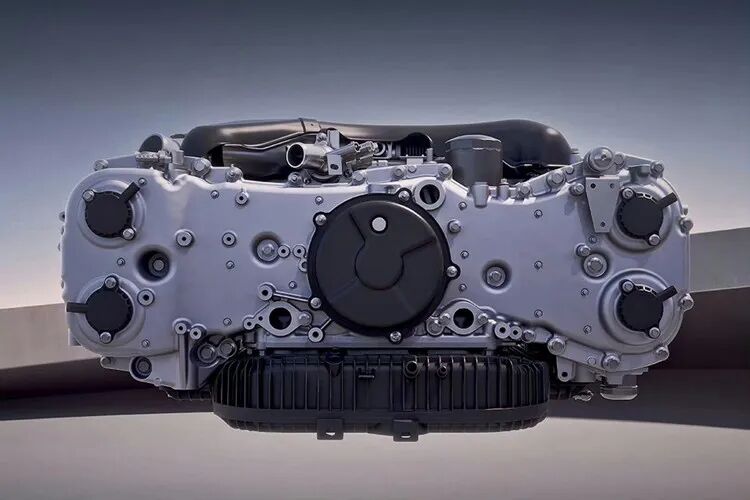

●Horizontally Opposed Range Extender

▲Representative Model: Yangwang U7

Currently, most EREVs utilize 1.5-2.0L inline four-cylinder engines as range extenders, which are essentially modifications of gasoline engines with electrification enhancements. For instance, crankshaft belt pulley systems have been largely phased out, and there are no flywheel/clutch components, emphasizing simplicity.

Even a luxury SUV like the Yangwang U8 follows a similar setup. However, for a low-slung coupe like the Yangwang U7, which needs to accommodate vector dual motors, an engine, a generator, and a complex Yunyan-Z damping system within a narrow engine compartment, it presents quite a challenge. Therefore, BYD Automobile has specially developed a horizontally opposed four-cylinder engine for use as a range extender.

Similar to a longitudinal V-type engine, the combustion chambers of this range extender are divided into two groups on the left and right, but with a 180° included angle. Additionally, the crankshaft configuration is optimized to allow the pistons to operate 'horizontally' and drive the rear generator for power generation. Combined with a dry oil sump, this design maximizes the compression of the engine height, thus freeing up sufficient space for the two vector motors below.

In addition to saving vertical space, this horizontally opposed range extender can also cancel out lateral vibrations through the counter-motion of corresponding pistons, resulting in superior normal NVH (Noise, Vibration, and Harshness) performance, an advantage not possessed by traditional inline four-cylinder engines.