ARBURG Exhibits at Chinaplas 2025

![]() 04/15 2025

04/15 2025

![]() 492

492

Tailored for Asia: Introducing the Allrounder E Golden Edition Electric Evo Series and Flexlift Robot Arm

●Local Solutions for Local Needs: Arburg presents intriguing technologies tailored to the Asian market at Chinaplas

●Highlights: Automotive, medical industry, and automation solutions

●Turnkey Provider: Arburg offers comprehensive services to customers

From April 15 to 18, 2025, Arburg will showcase captivating technologies tailored to the Asian market at Chinaplas, held in Shenzhen, China. At booth F41 in hall 12, two Allrounder E Golden Edition Electric Evo series will exhibit reliable LSR production and efficient medical product manufacturing. Centered around the Allrounder vertical turntable machine, the turnkey system will fully automate the production of connector components for China's burgeoning automotive sector. The special exhibition area of arburgSOLUTIONworld, encompassing automation, digitization, and service themes, will complete the exhibition presentation.

'Chinaplas serves as the most significant platform in Asia to demonstrate our "Local Solutions for Local Needs" strategy. With the Allrounders Golden Edition Electric Evo series and Flexlift robot arm, we present products specifically designed for Chinese and Asian customers, offering cost-effectiveness and swift delivery times. Moreover, we design and manufacture local automation solutions in Pinghu,' explains Tong Chao, General Manager of Arburg China. 'As a technology and system partner, we provide comprehensive support to customers, ranging from single injection molding machines to turnkey solutions, digitization, and our services.'

Electric Production of LSR Parts and Medical Products

The two Golden Edition Electric Evo series at Chinaplas fully showcase the capabilities of Allrounder electric injection molding machines. Compared to standard hydraulic machines, dry cycle times can be reduced by up to two seconds, and energy requirements can be cut by up to 50%.

The Allrounder 470 E Golden Edition Electric Evo, with a clamping force of 1000 kN, utilizes Fangyi's 160-cavity cold runner mold to produce burr-free sealing elements weighing 0.06 grams each from Wacker's liquid silicone rubber (LSR) with an injection accuracy of 0.01 mm. These LSR injection molded parts protect individual wires in automotive connectors from liquid penetration.

The Allrounder 570 E Golden Edition Electric Evo, featuring a clamping force of 2000 kN, will demonstrate the efficient production of prefilled syringes using COP (cyclic olefin polymer), a glass substitute material. COP is transparent and possesses barrier properties similar to glass but is virtually unbreakable and more cost-effective to produce. The exhibit is equipped with an 8-cavity mold from Younaixin. The Flexlift 10 linear robot arm gently removes the syringes from the mold and places them on a conveyor belt.

Turnkey System for Fully Automated Overmolding of Injection Molded Inserts

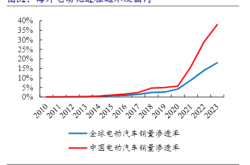

Electric vehicles and the automotive industry as a whole are gaining prominence in China. An advanced turnkey system tailored to this industry will be exhibited at Chinaplas 2025. The Allrounder 1600 T vertical turntable machine, with a clamping force of 2000 kN, sequentially overmolds metal inserts into high-voltage modules for automotive connectors. A small six-axis robot feeds the inserts into the system via a transfer platform and stacks the finished parts. A second large six-axis robot places the metal inserts into the half-mold of the injection mold. After overmolding with glass fiber-reinforced PBT, it transfers the pre-molded part to the rear half of the mold, where the finished part is produced by overmolding again.

Comprehensive Offerings: Automation, Digitization, Service

With decades of expertise in injection molding, automation, and digitization, Arburg offers a broad spectrum of services enabling customers to manufacture products efficiently, swiftly, and to a high standard. The arburgSOLUTIONworld exhibition area brings together consulting expertise on all these topics. Arburg experts will also address individual queries and introduce the Arburg Central Management System ALS, the arburgXworld customer portal, as well as a range of spare parts and calibration services. Flexlift will also be in the spotlight. This modular linear robot arm can be precisely customized to individual requirements, for instance, with application-specific drives, valve blocks, and variable control cabinet positioning.

470E Golden Edition Electric Evo and Flexlift

At Chinaplas 2025, Arburg will exhibit two versatile products, the Golden Edition Electric Evo and Flexlift robot arm, both specifically designed for Chinese and Asian customers.

About Arburg

Founded in 1923, the German family-owned company is a leading global manufacturer of plastic processing machinery. The ARBURG family also includes AMKmotion and ARBURGadditive, encompassing innovatiQ.

The product portfolio comprises injection molding machines, 3D printers for industrial additive manufacturing, robotic systems, and customer- and industry-specific turnkey solutions. It also encompasses digital products and services.

ARBURG is a pioneer in the plastics industry regarding energy and production efficiency, digitization, and sustainability. ARBURG machines are used to manufacture plastic products in sectors such as mobility, packaging, electronics, medical, construction, equipment engineering, and leisure.

The company's headquarters are in Lossburg, Germany. Additionally, ARBURG has its own organizations at 37 locations in 27 countries and is represented in over 100 countries through trading partners. Of the approximately 3700 employees, around 3100 work in Germany, and around 600 are part of the ARBURG global organization.

ARBURG is certified according to ISO 9001 (quality), ISO 14001 (environment), ISO 27001 (information security), ISO 29993 (training), and ISO 50001 (energy).