The Ultimate Guide: Unveiling the Four Key Trends in Optical Waveguide Development for 2026-2027

![]() 02/04 2026

02/04 2026

![]() 521

521

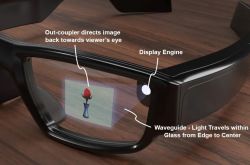

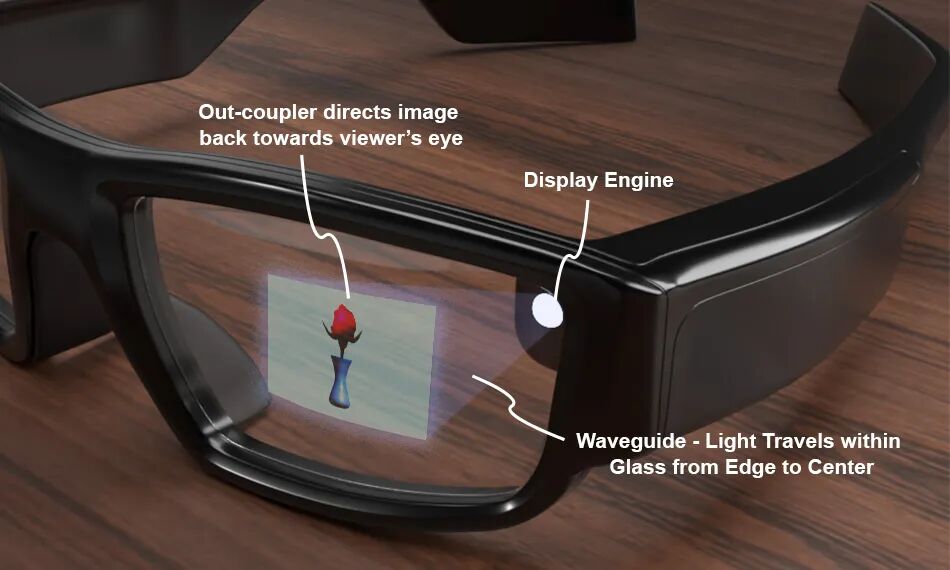

When delving into the realm of AR glasses, it's essential to acknowledge the pivotal role of optical waveguides. These components act as the 'periscope' and 'portal' within AR lenses, meticulously transferring images from a side-mounted micro-projector to your field of view through diffraction or reflection. This process not only expands the tiny images from the optical engine but also ensures a clear view of the real world. Presently, the parameters and performance of optical waveguides are the direct determinants of the AR glasses experience.

However, a topic of fervent discussion recently is: Will 2026 mark the dawn of silicon carbide optical waveguides? Which optical waveguide solution will emerge as the mainstream in 2026-2027? What novel technologies in optical waveguides will shape the future of the AR glasses industry? Today, let's delve deeper into these questions.

Not long ago, SPIE Photonics West, the premier annual event for photonics, lasers, and biomedical optics, took place in the United States. At SPIE and its dedicated XR section, SPIE AR | VR | MR, numerous global XR optical companies showcased their cutting-edge expertise.

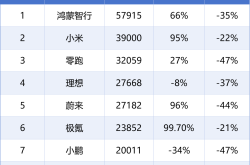

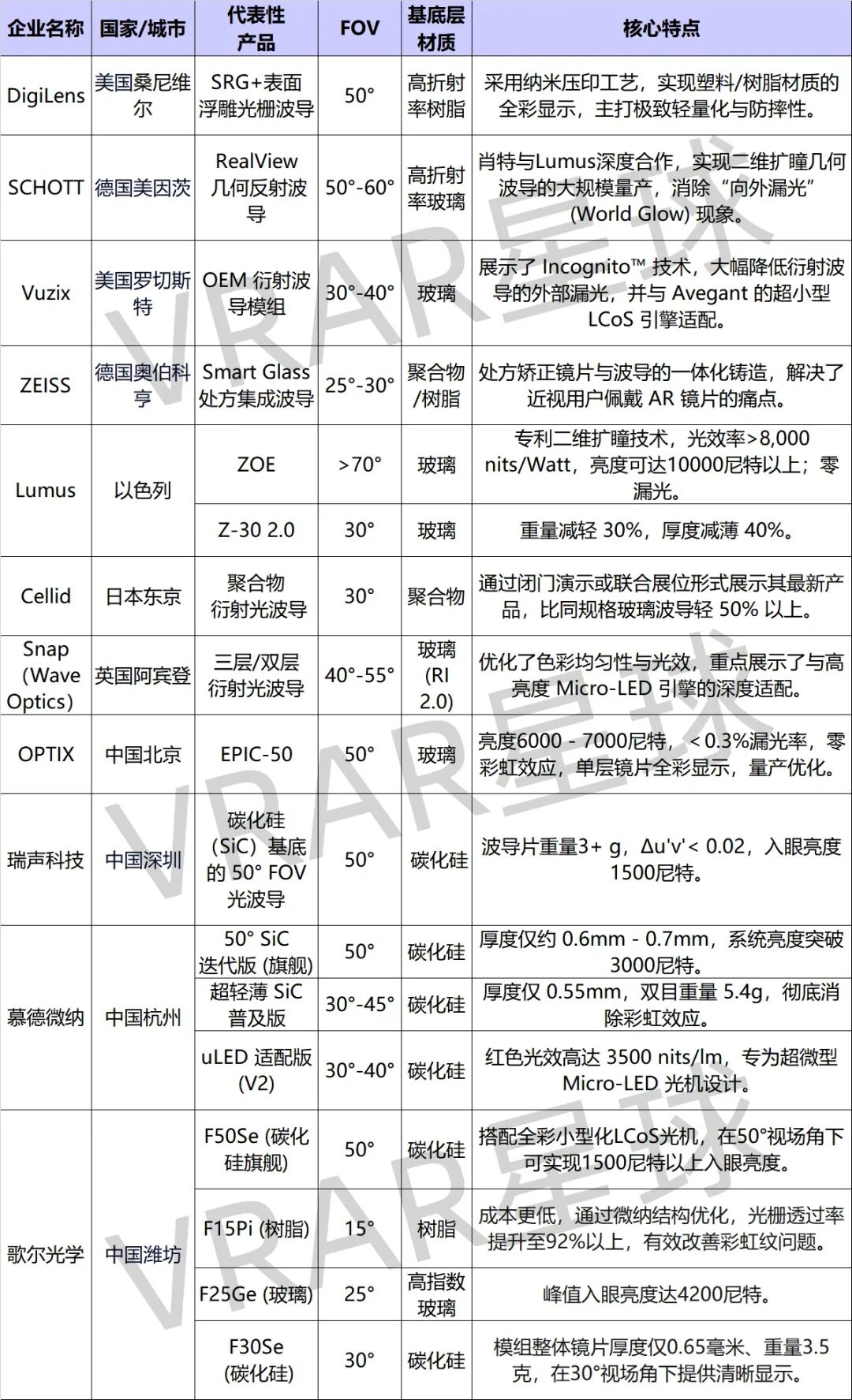

So, what technological trends in optical waveguide development can we discern at this premier international optics event, SPIE? Let's first take stock of the vendors who participated this year, the technologies they brought, and the highlights they presented. Refer to the table below (the most comprehensive online, a must-have for enthusiasts):

*Click on the image to enlarge for detailed information. Source: VRAR Planet

Although the exhibition has concluded, a review of this year's SPIE Photonics West and SPIE AR | VR | MR reveals several significant trends in optical waveguide technology:

Firstly, optical waveguides utilizing various substrate materials are pushing the boundaries of physical limitations. For instance, Goertek and Mude Micro-Nano's silicon carbide optical waveguides significantly reduce the weight and thickness of AR glasses, while Lumus expands the FOV (Field of View) of geometric waveguides on glass substrates to unprecedented levels. DigiLens' SRG+ process, an enhanced version based on its holographic polymer material, focuses on merging the high efficiency of holography with the scalability of diffraction for mass production.

The emphasis on 'eliminating rainbow patterns' or 'minimizing light leakage' indicates that diffractive waveguides are approaching the visual purity of geometric reflection solutions. This suggests that the AR glasses experience in 2026-2027 will soon reach new heights.

Secondly, while silicon carbide is a rising trend, it won't dominate the market. The 2026 SPIE event highlighted impressive strides by Chinese companies like Goertek and Mude Micro-Nano in silicon carbide solutions. They've reduced the thickness of optical waveguides to 0.55mm-0.65mm, with a single-eye weight as low as around 3g. In terms of thinness and lightness, the silicon carbide solution undoubtedly leads. This will inevitably drive AR glasses towards the form factor of ordinary glasses.

However, the processing technology for silicon carbide optical waveguides is still immature, with limitations in dispersion control. In contrast, resin and glass substrate materials also offer distinct advantages. For 'all-weather wear' and 'low-cost mass production' scenarios, the extreme lightness and low cost of resin materials ensure they won't be replaced by silicon carbide anytime soon. Glass materials, on the other hand, can achieve higher performance and a wider FOV, suitable for 'mobile cinemas' and 'immersive gaming' scenarios. Therefore, it's anticipated that the optical waveguide market in 2026-2027 will bifurcate into two major streams: ultra-lightweight and high-performance wide-angle types.

Thirdly, the potential audience for AR glasses may expand to the general population. Previously, nearsighted users wearing AR glasses had to install an additional frame inside, fit it with optical lenses, and then attach prescription lenses to the AR glasses. This resulted in uncontrollable weight and a poor experience with double lenses, limiting the audience to mainly non-nearsighted individuals.

At this exhibition, Zeiss introduced an integrated casting technology for prescription corrective lenses and waveguides, where the same lens serves dual purposes as an optical waveguide lens and a prescription corrective lens. This addresses the pain point for nearsighted users wearing AR glasses, indicating that Zeiss has taken the lead in unlocking the mass market. Given the large number of nearsighted individuals among young people in China, domestic lens companies should pay close attention and actively respond to this change.

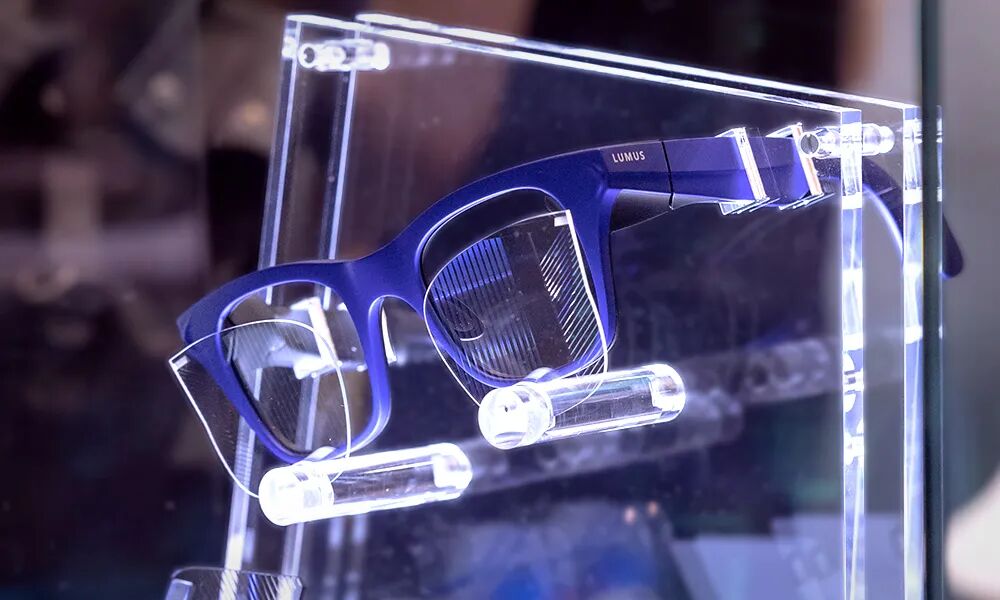

Fourthly, collaborative mass production processes will become a competitive edge. Examples include the deep cooperation between Germany's SCHOTT and Israel's Lumus, the optical engine adaptation between US-based Vuzix and Avegant, and China's AAC Technologies and its acquired Finnish company Dispelix's end-to-end mass production model. All these scenarios reflect a global shift among optical waveguide companies from single-point technology R&D to collaborative mass production processes.

Some new technologies not only simplify mass production but also spark competition in this area. For instance, while nanoimprint technology is currently widely used for processing optical waveguides in China, the emergence of DTL technology (Displacement Talbot Lithography) at this SPIE event may prove more suitable for mass production of AR glasses than nanoimprint. The evolution of mass production tools for AR glasses will directly impact product costs and prices. Therefore, the future competition lies not only in designing superior products but also in mass-producing them with high precision and low cost.

In conclusion, three factors will constrain the development of AR glasses products in 2026-2027: on one hand, the rapidly evolving technology of optical waveguides, determining whether display effects can be enhanced and weights reduced; on the other hand, factors invisible to C-end users, such as the yield, cost, shipment volume, and shipment cycle of mass production processes; and finally, the influence of media promotion on public perception.