Revolutionizing Electric Drive Efficiency and Cost: The Vaionic iPSM with Ironless Stator

![]() 01/19 2026

01/19 2026

![]() 594

594

In the fiercely competitive landscape of the new energy vehicle (NEV) industry, the electric drive system stands as the pivotal "heart," directly influencing a vehicle's range, performance, and market competitiveness through its efficiency, weight, and cost. While traditional Permanent Magnet Synchronous Motors (PSMs) are prevalent, their inherent drawbacks—such as excessive stator iron losses, high material consumption, and elevated costs—have consistently impeded industry progress. Enter Vaionic, a Berlin-based innovator, offering a groundbreaking solution with its innovative Ironless Permanent Magnet Synchronous Motor (iPSM).

Today, we delve into the core logic of this "ironless stator" electric drive system—how it transcends traditional limitations through structural innovation, achieves holistic optimization in efficiency, weight, and cost, and leverages its robust capabilities validated by Tier 1 suppliers.

I. Vaionic: German Innovation in Electric Drive Technology

Headquartered in Berlin's WISTA Science and Technology Park, Vaionic is a pioneering enterprise dedicated to the research, development, prototyping, and testing of electric drive systems. With a team of approximately 35 full-time employees, 85% of whom are engineers, the core team brings years of deep expertise in the electric drive sector. Leveraging profound insights into industry pain points, they developed the revolutionary iPSM.

As a technology-driven startup, Vaionic prioritizes not only product innovation but also engineering implementation. Its technology has undergone rigorous validation by Tier 1 suppliers, with multiple designs protected by patents (3 granted patents, several others pending), steadily transitioning from the laboratory to real-world applications.

II. Industry Landscape: Challenges of Traditional PSMs in Efficiency and Cost

To appreciate the innovative value of the iPSM, one must first understand the current state and bottlenecks of traditional Permanent Magnet Synchronous Motors (PSMs) in the automotive sector.

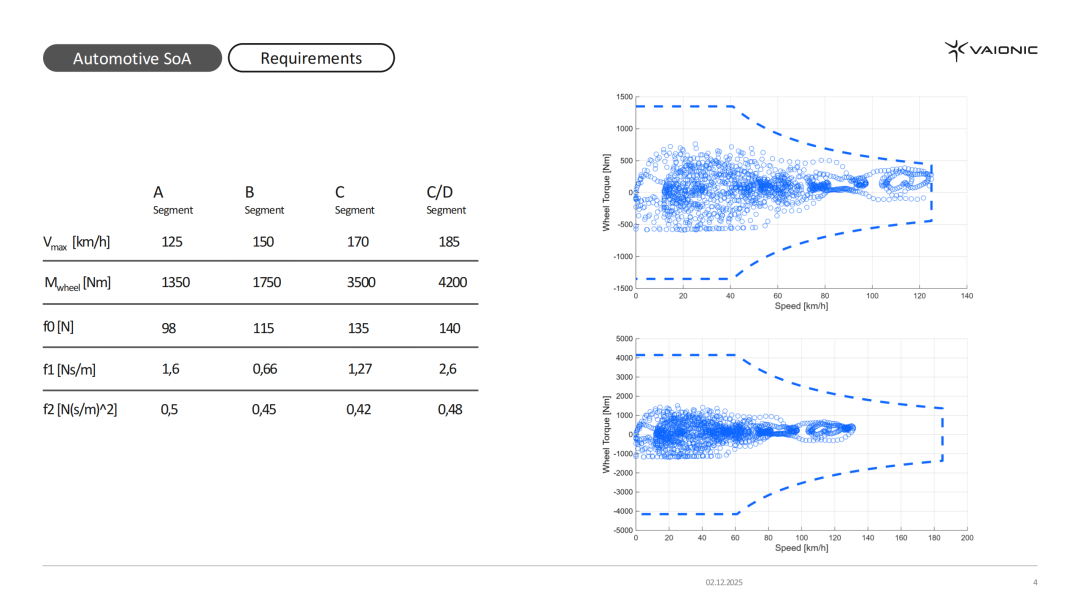

1. Performance Demands Across Vehicle Segments

Automotive requirements for electric drives vary by vehicle class, with core metrics like top speed and wheel torque progressively increasing from A-segment to C/D-segment cars:

- A-segment: Top speed 125 km/h, wheel torque 1,350 Nm

- B-segment: Top speed 150 km/h, wheel torque 1,750 Nm

- C-segment: Top speed 170 km/h, wheel torque 3,500 Nm

- C/D-segment: Top speed 185 km/h, wheel torque 4,200 Nm

These demands necessitate continuous breakthroughs in efficiency and power density for electric drive systems, yet traditional PSMs struggle to balance all metrics.

2. Efficiency Bottlenecks: Stator Iron Loss as a Major Energy Drain

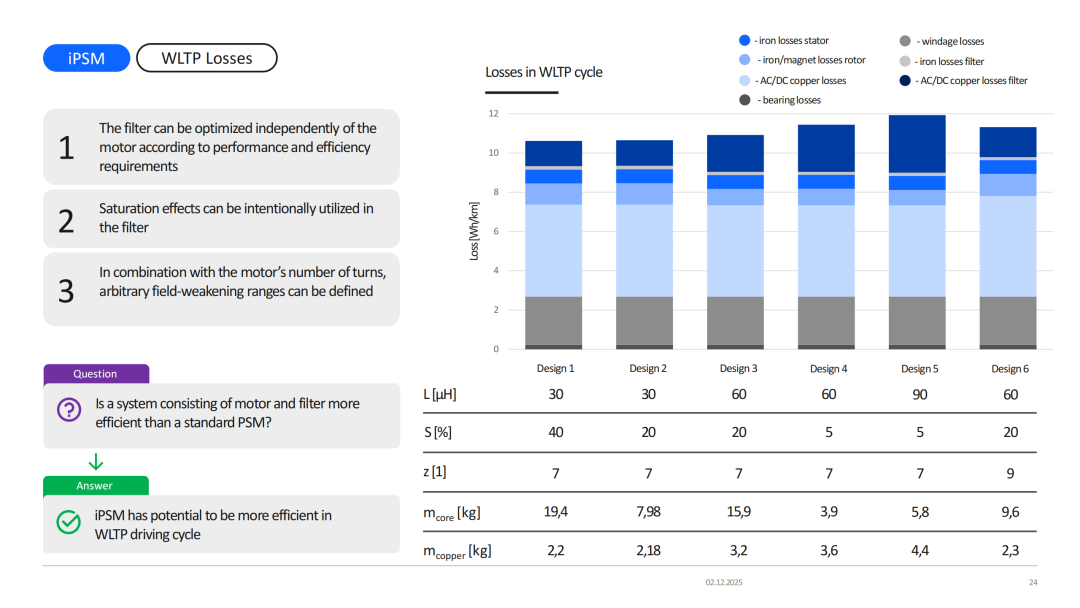

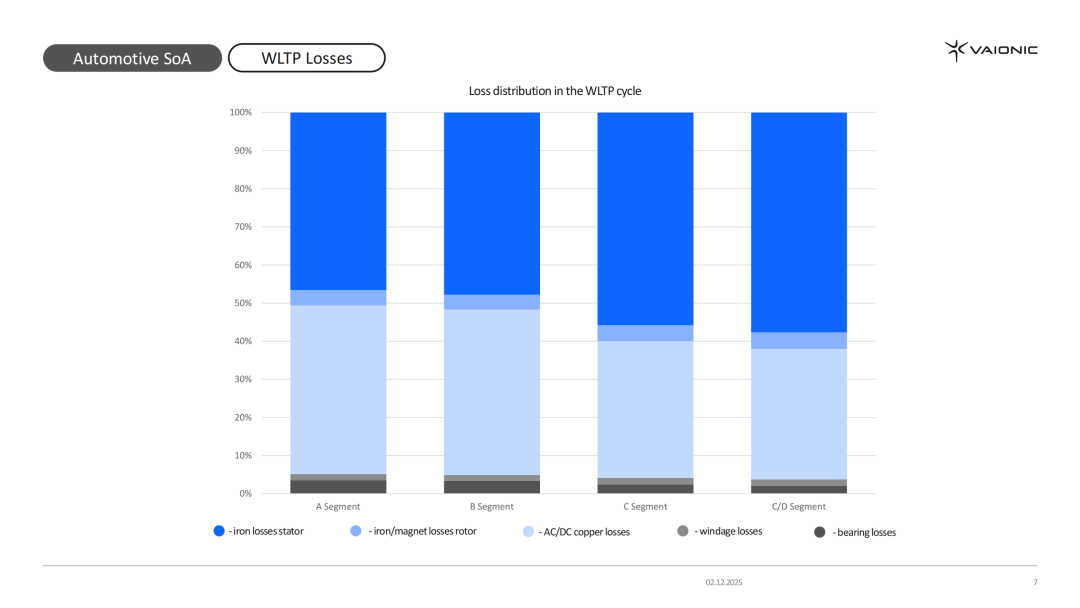

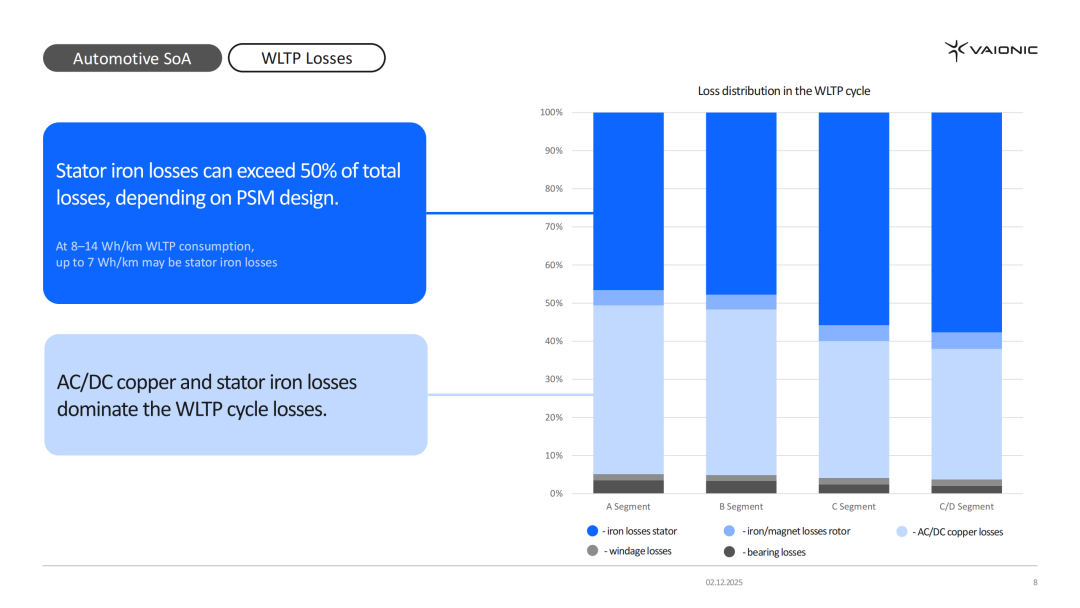

Energy losses in motor operation primarily include stator copper loss, stator iron loss, rotor iron/magnet loss, windage loss, and bearing loss. During the WLTP (Worldwide Harmonized Light Vehicles Test Procedure, simulating real-world driving conditions), traditional PSMs exhibit distinct pain points in loss distribution:

- Dominant stator iron loss: Depending on PSM design, stator iron loss can exceed 50% of total losses.

- Severe energy waste: In WLTP cycles, traditional PSMs consume 8–14 Wh/km, with stator iron loss accounting for up to 7 Wh/km.

- Core losses dominate: Stator iron loss and AC/DC copper loss together constitute the majority of WLTP cycle losses, constraining efficiency gains.

The essence of stator iron loss lies in eddy current and hysteresis losses generated in the iron core under alternating magnetic fields—an inherent flaw of traditional iron-core stator structures. As long as the stator contains an iron core, frequency-dependent losses from magnetic field variations are unavoidable.

3. Design Limitations: High Material Consumption and Costs

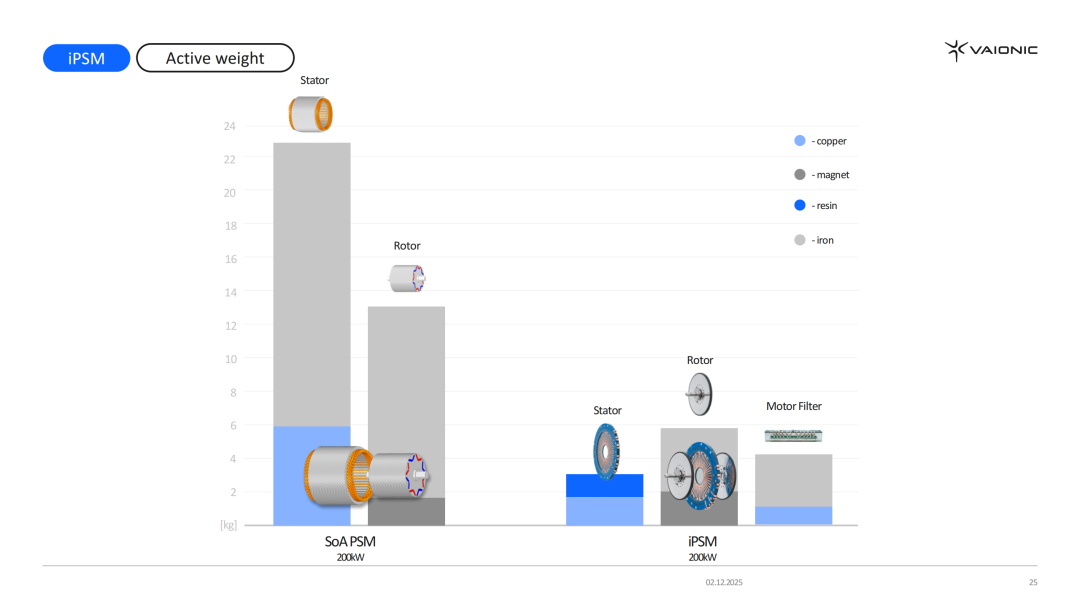

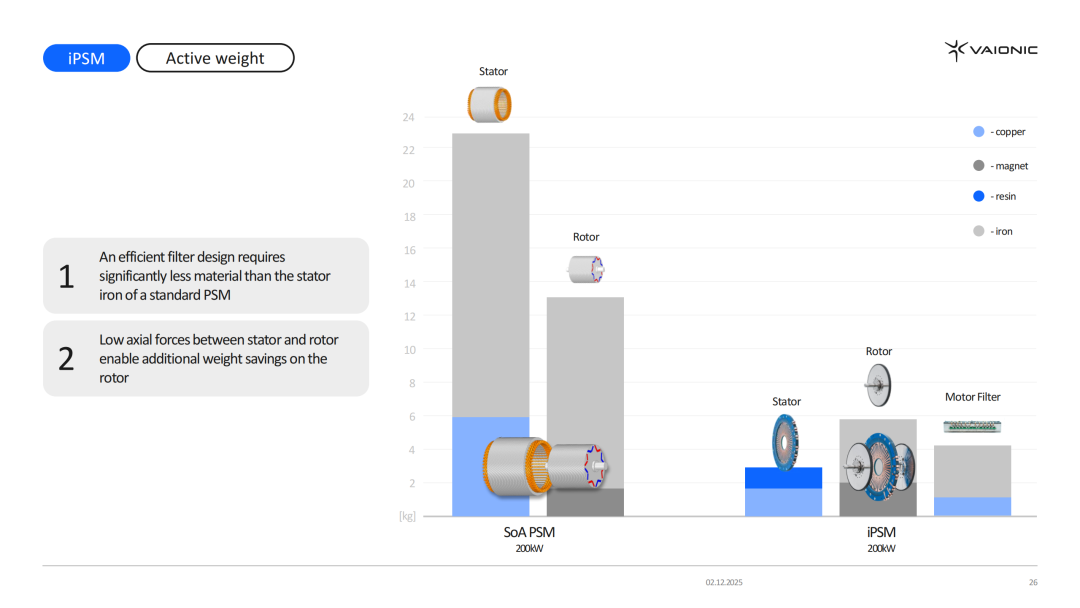

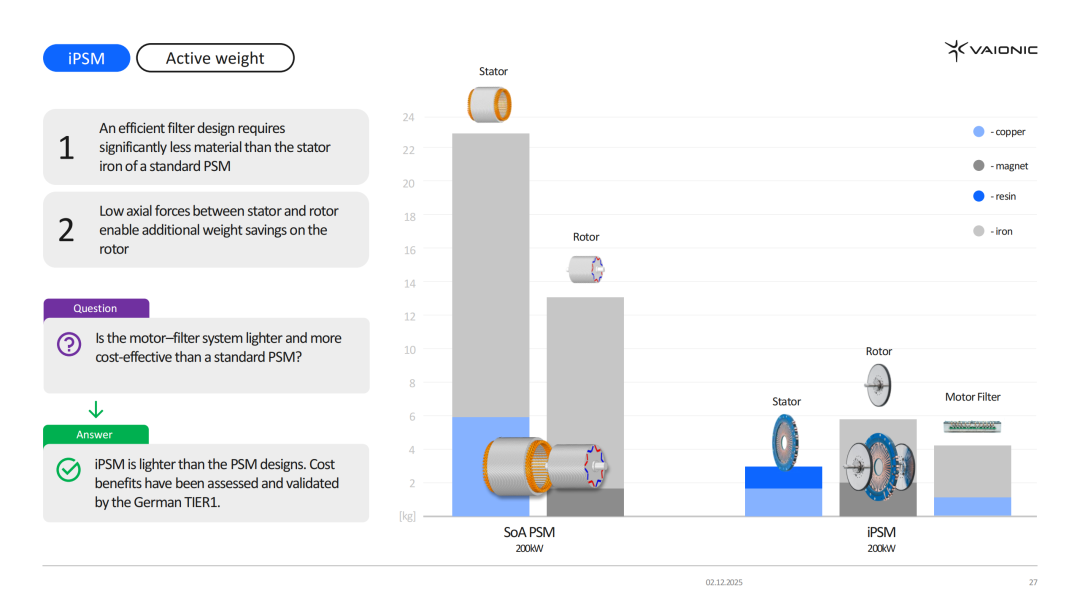

Traditional PSMs require substantial high-quality silicon steel sheets for stator cores, while rotor structures demand thicker materials due to axial forces, leading to:

- Excessive active material weight: Optimizing copper, iron, and magnet usage is challenging.

- Prohibitive manufacturing costs: Complex processes like core lamination and winding insertion drive up material and processing expenses.

- Assembly and recycling difficulties: Multiple components and intricate structures increase maintenance and recycling costs.

These pain points render traditional PSMs increasingly inadequate in meeting the NEV industry's core demands for "cost reduction and efficiency enhancement."

III. iPSM Core Innovation: A Bold Breakthrough with Ironless Stators

Addressing traditional PSM limitations, Vaionic proposes a disruptive concept: removing iron and copper from the motor stator and integrating them as external components (e.g., filters) to achieve superior balance in weight, cost, and efficiency. This concept materializes as the iPSM (Ironless PSM, Ironless Permanent Magnet Synchronous Motor).

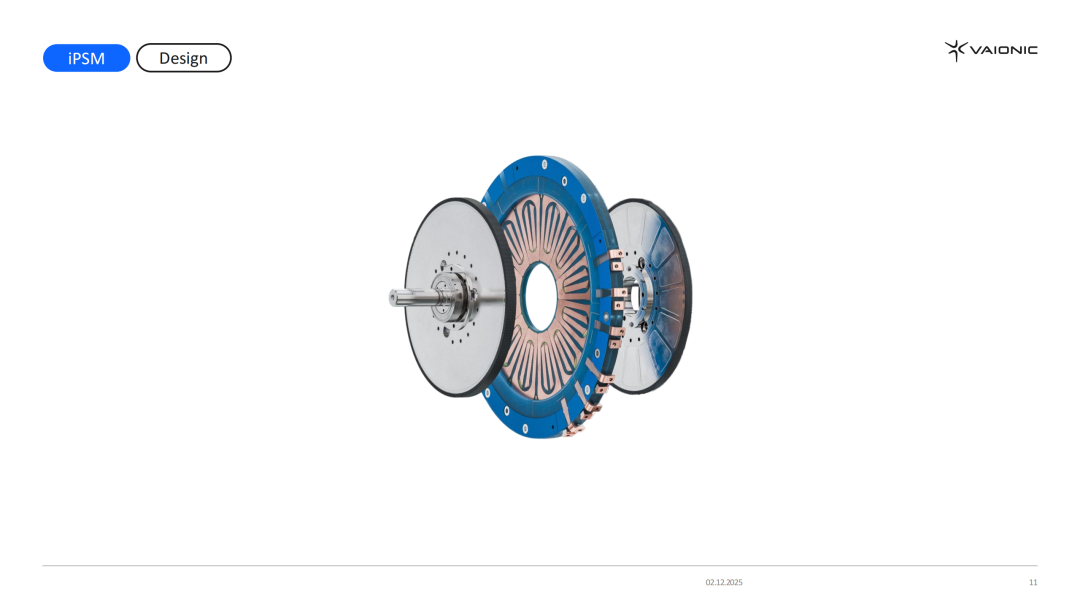

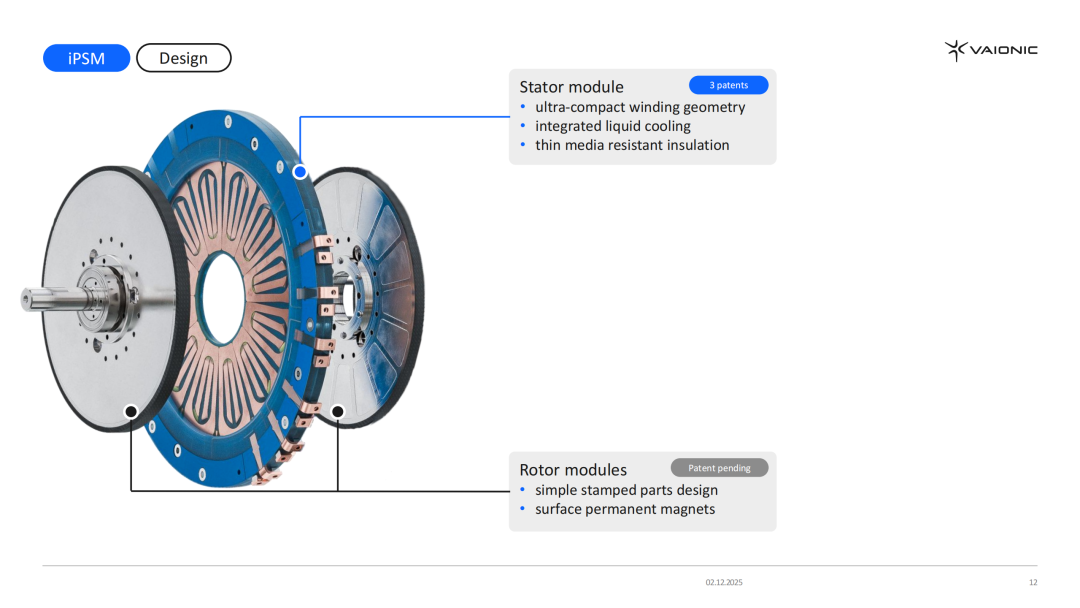

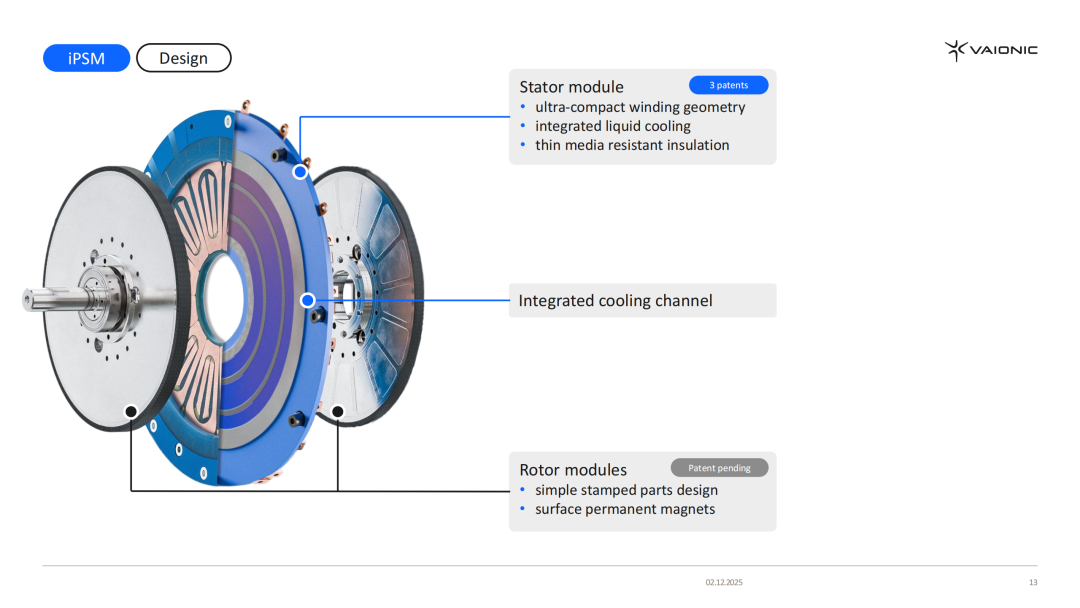

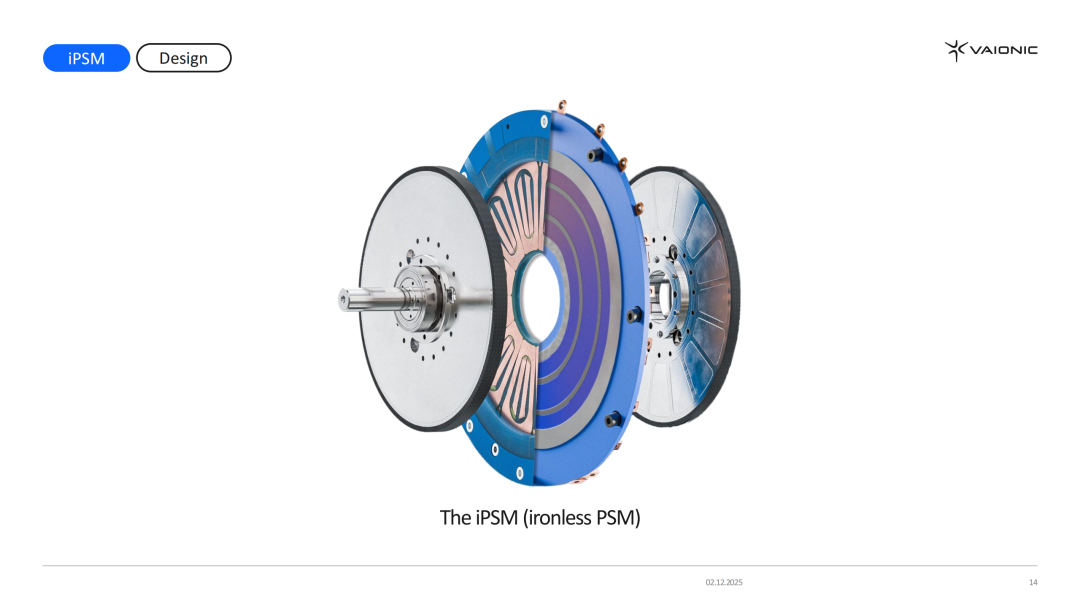

1. iPSM Core Design: Minimalist yet Highly Efficient

The innovation hub of the iPSM lies in its "ironless stator," featuring a highly optimized structural design:

- Stator Module: Utilizes ultra-compact winding geometry with integrated liquid cooling and dielectric-resistant thin insulation. Without an iron core, stator manufacturing is drastically simplified—a design validated by Tier 1 suppliers for scalable production.

- Rotor Module: Adopts simple stamped parts paired with surface-mounted permanent magnets, ensuring structural simplicity and reliability. Meanwhile, the ironless design eliminates magnetic resistance between stator and rotor, enabling smoother rotor operation.

- Patent Protection: The entire design is secured by 3 granted patents, with several others pending, forming a complete technological barrier.

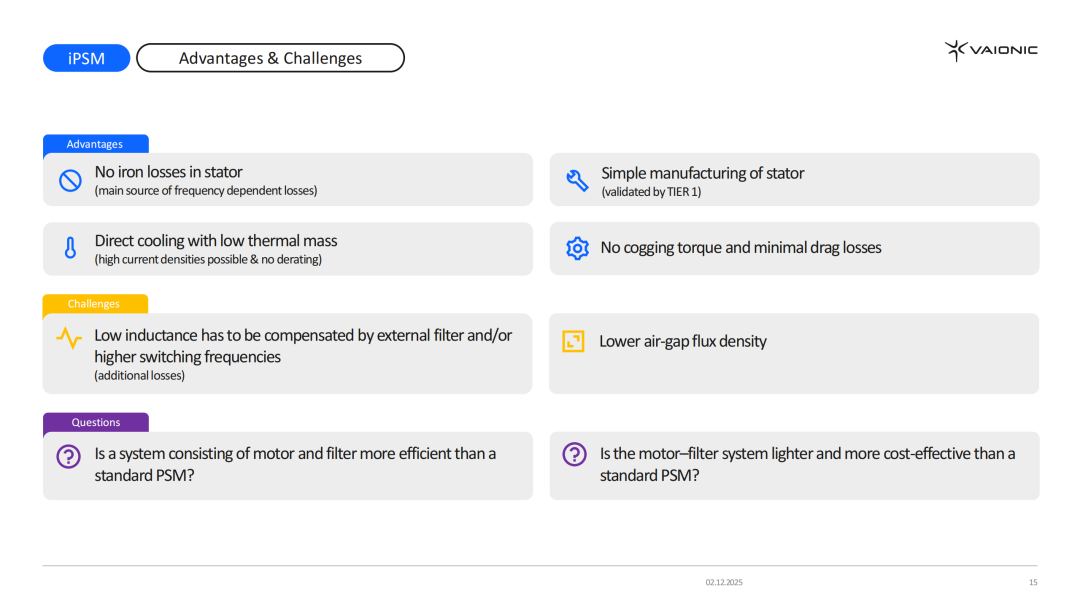

2. Direct Advantages of the Ironless Design

Compared to traditional PSMs, the iPSM's ironless stator directly resolves multiple core pain points:

- Zero stator iron loss: The most critical advantage—without an iron core, eddy current and hysteresis losses are eliminated, eradicating the largest energy loss source in traditional PSMs.

- No cogging torque + minimal drag loss: Cogging torque, a periodic resistance caused by interactions between stator slots and rotor magnets in traditional iron-core motors, is entirely avoided in the iPSM's ironless structure, ensuring smoother operation and significantly reduced drag loss.

- Direct cooling + no derating: Stator windings directly connect to the cooling system, boasting extremely low thermal mass and high heat dissipation efficiency. This allows the motor to handle higher current densities without "derating" (inability to maintain rated power output due to winding overheating).

- Simplified manufacturing: Eliminating iron core processing simplifies winding techniques, reduces assembly steps, and drastically lowers error tolerance costs in production.

3. Unavoidable Challenge: Compensation for Low Inductance

The ironless design introduces a technical challenge: extremely low stator inductance. Low inductance increases current ripple during motor operation, necessitating external filter compensation or higher switching frequencies—both of which introduce additional losses.

This raises two critical questions: Is the iPSM system (motor + filter) more efficient than traditional PSMs? Does it offer lighter weight and greater cost advantages?

Through extensive simulations and real-world testing, Vaionic provides affirmative answers—with the core breakthrough lying in "filter design freedom."

IV. Filter Design Freedom: The Hidden Advantage of iPSM

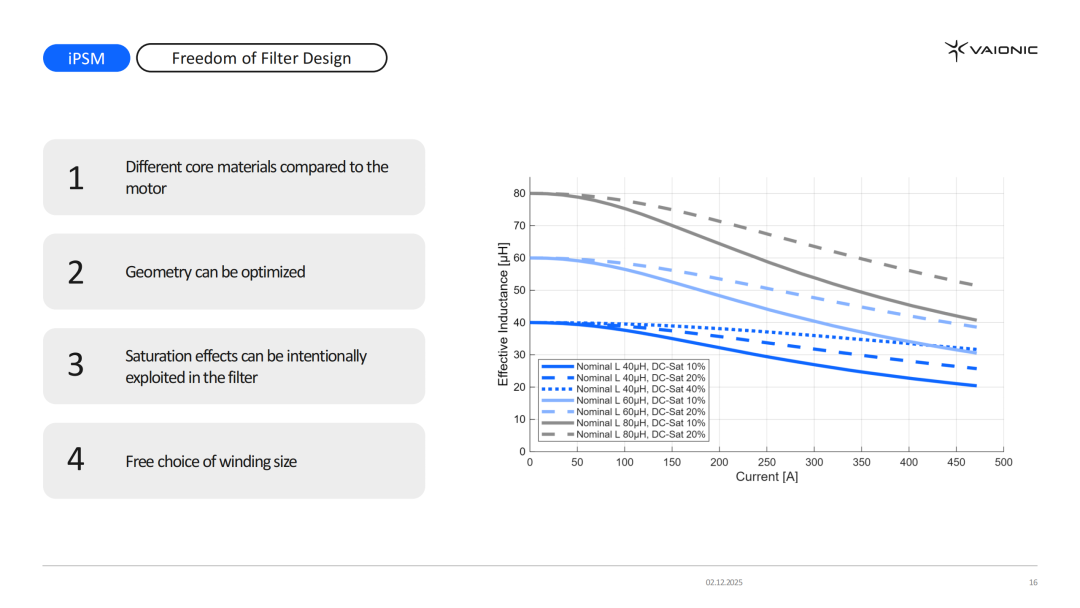

Traditional PSM filters are constrained by internal motor space, material selection, and structural limitations, offering minimal optimization potential. In contrast, the iPSM's filter operates as a fully independent external component, granting unparalleled design flexibility—a key factor enabling the iPSM system to surpass traditional PSMs.

1. Four Dimensions of Filter Design Freedom

The iPSM's filter escapes motor confinement, enabling all-around optimization:

- Material Freedom: Allows selection of iron core materials entirely distinct from the motor, enabling flexible trade-offs between losses and costs.

- Geometric Optimization Freedom: Filter structure geometry can be independently designed without adapting to motor internal space, maximizing filtering efficiency.

- Saturation Effect Utilization Freedom: Intentionally leverages filter core saturation effects to optimize performance under specific operating conditions (whereas saturation is typically a negative factor to avoid in traditional PSMs).

- Winding Dimension Freedom: Parameters like winding turns and wire diameters can be freely selected without stator structural constraints.

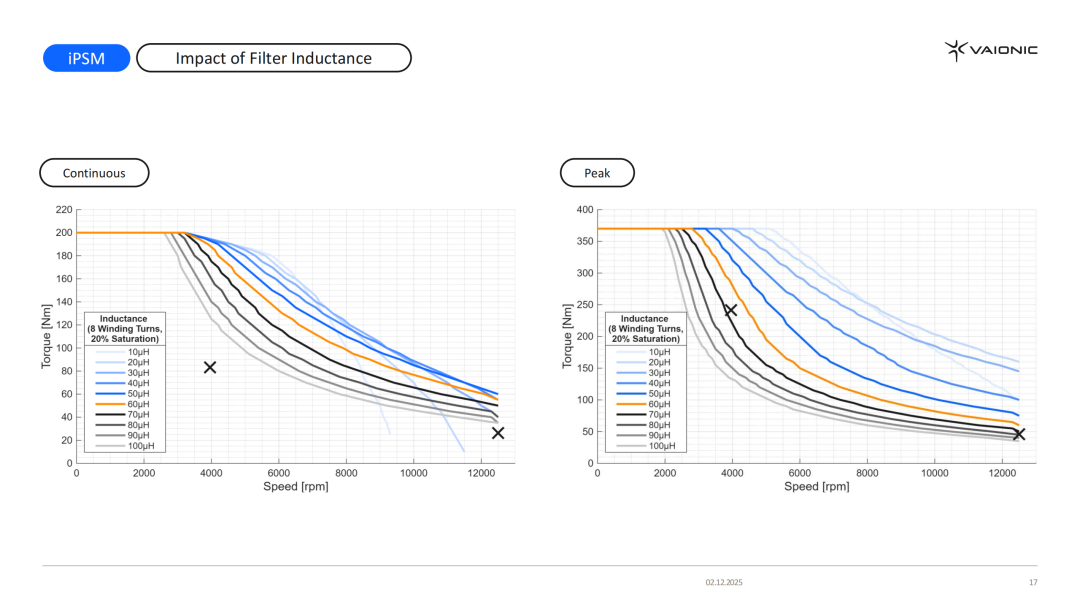

2. Impact of Design Parameters on Performance

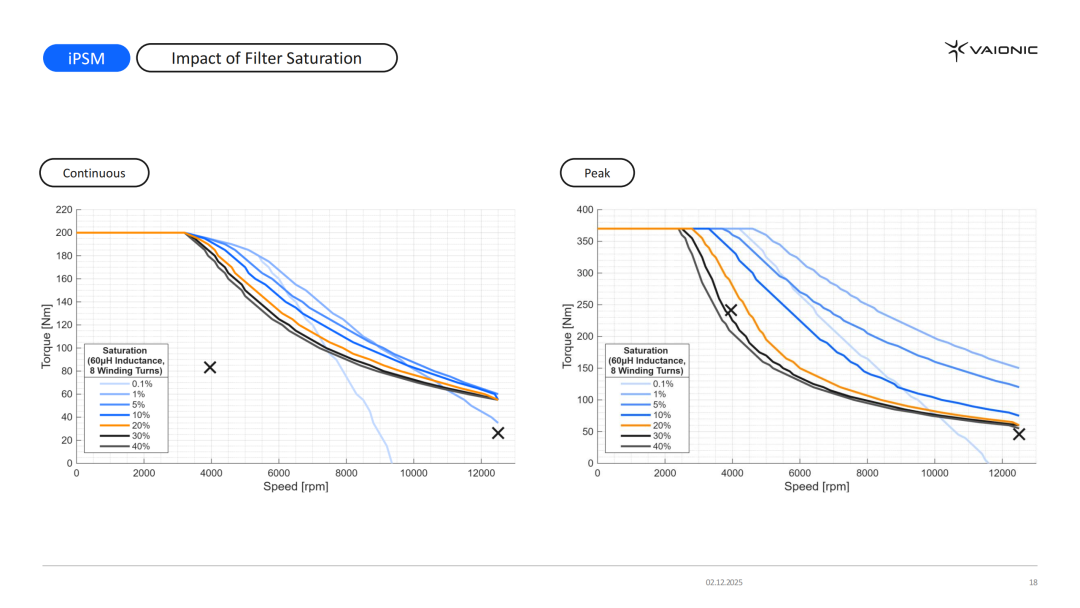

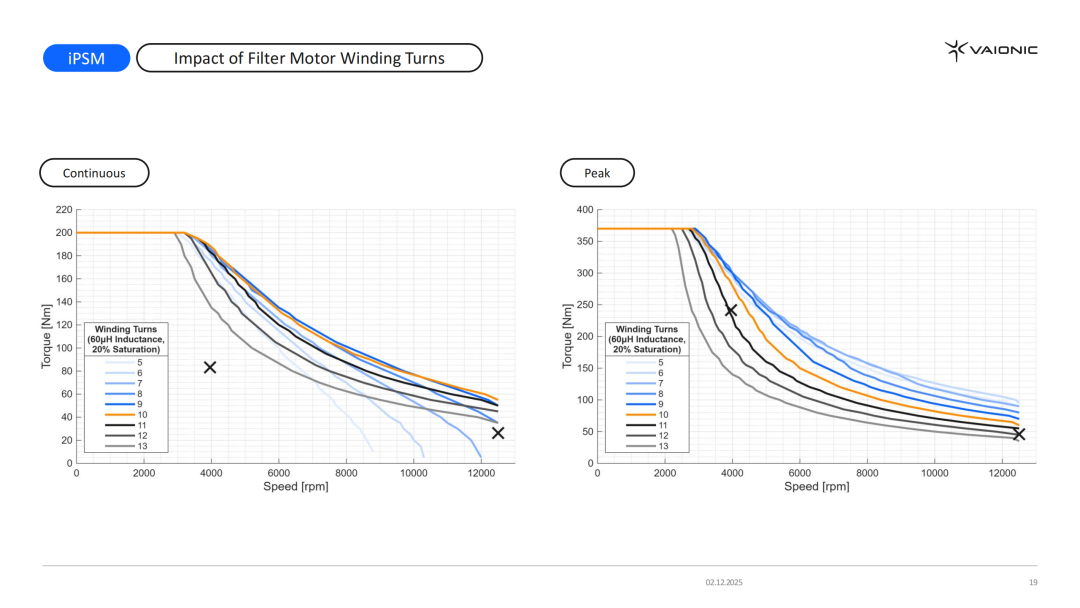

Vaionic's extensive testing validates how key filter parameters influence iPSM system performance:

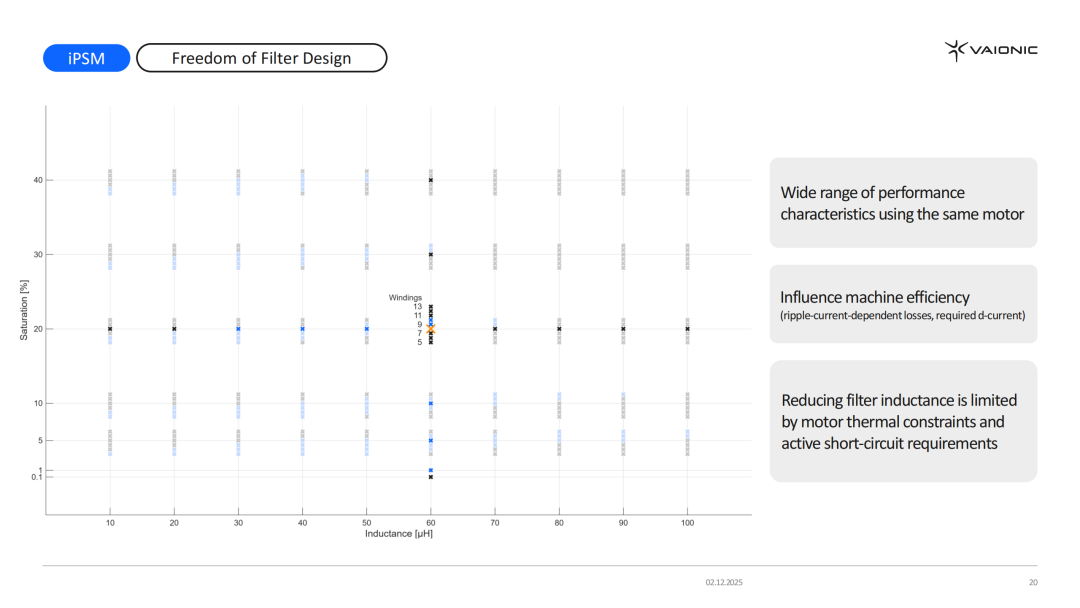

- Inductance (L): Different inductance values directly affect continuous and peak torque. Tests show that under 8 winding turns and 20% saturation, increasing inductance from 10 μH to 100 μH maintains peak torque around 350 Nm and continuous torque near 180 Nm, ensuring stable performance.

- Saturation Rate (S): When saturation rises from 0.1% to 50%, continuous and peak torque exhibit no significant decay, proving that intentional saturation utilization is feasible without compromising performance.

- Winding Turns (z): With 60 μH inductance and 20% saturation, increasing winding turns from 6 to 13 stabilizes continuous torque between 120–180 Nm and peak torque at 300–350 Nm, meeting performance demands across vehicle segments.

3. Core Value of Design Freedom

Filter design freedom grants the iPSM system exceptional adaptability:

- Single Motor for Multiple Performance Tiers: By adjusting filter inductance, saturation, and winding turns, one iPSM motor can meet performance requirements across A/B/C/C/D segments, eliminating the need for separate motor development per vehicle model and drastically reducing R&D costs.

- Controllable Losses: Filter losses can be minimized through material and geometric optimization, and the filter avoids frequency-dependent losses caused by rotor magnetic fields (the primary source of traditional PSM stator iron loss), resulting in lower overall system losses than traditional PSMs.

- Balancing Thermal Management and Safety: While reducing filter inductance is constrained by motor thermal limits and active short-circuit requirements, design freedom allows engineers to strike an optimal balance between "loss, performance, and safety."

V. Efficiency Measurement: Impressive Performance in WLTP Cycle

To verify the efficiency of the iPSM system, Vaionic designed six filter schemes with different parameters (core parameters are listed in the table below) and conducted loss tests in the WLTP cycle.

| Design Scheme | Inductance L (μH) | Saturation Rate S (%) | Number of Winding Turns z (turns) | Core Weight mcore (kg) | Copper Weight mcopper (kg) |

|---|---|---|---|---|---|

| Design 1 | 30 | 40 | 7 | 19.4 | 2.2 |

| Design 2 | 30 | 1. Weight Advantage: Substantial Reductions in Active Material Usage Vaionic carried out a weight comparison between a 200kW-class iPSM system and traditional PSM, yielding the following results: Stator Material Savings: The iPSM stator eliminates the need for an iron core. Additionally, optimized windings lead to reduced copper consumption, resulting in a significant decrease in the overall stator weight. Rotor Weight Optimization: The coreless design substantially reduces the axial force between the stator and rotor. This, in turn, removes the necessity for heavy structural support in the rotor and further cuts down on the material usage for magnets and stampings. Controllable Filter Weight: Although an external filter is incorporated, the iron core and copper requirements of this filter are considerably lower than those of the stator iron core in traditional PSM. Overall, the total weight of active materials (stator + rotor + filter) in the iPSM system is notably less than that in traditional PSM. 2. Cost Advantage: Credibility Backed by Tier 1 Suppliers The reduction in weight directly translates to a decrease in material costs. Meanwhile, the streamlined manufacturing process further brings down production and assembly expenses. More significantly, Vaionic's iPSM design has undergone cost evaluations and received verifications from German Tier 1 suppliers. This professional supplier endorsement confirms that the cost advantage of iPSM is feasible in large-scale production, rather than being merely a theoretical value in the laboratory phase. In a nutshell, the iPSM system not only outperforms traditional PSM in terms of weight but also offers comprehensive benefits in material costs, manufacturing costs, and assembly costs.

VII. Conclusion: Why iPSM Represents the Future of Electric Drives Vaionic's iPSM, through its core innovation of a 'coreless stator,' not only tackles the efficiency challenges of traditional PSM but also achieves breakthroughs in weight and cost. Its core value can be distilled into three key points: 1. Efficiency Revolution: From 'Reducing Losses' to 'Eliminating Losses' Traditional PSM efficiency optimizations mainly focus on 'reducing losses' (such as minimizing copper losses and optimizing core materials). In contrast, iPSM directly 'eliminates' the largest proportion of stator iron losses, fundamentally enhancing efficiency. At the same time, the flexible design of the filter allows for controllable system losses, and the measured performance in the WLTP cycle attests to its superiority. 2. Design Freedom: From 'Model Adaptation' to 'One Motor, Multiple Capabilities' The separate design of the iPSM motor body and filter enables one motor to be adapted to all vehicle models from A to C/D classes by adjusting filter parameters. This significantly cuts down on the R&D costs and supply chain complexity for automakers while simplifying production and assembly processes. 3. Cost and Weight: From 'Trade-offs' to 'Comprehensive Optimization' In traditional electric drive systems, efficiency, weight, and cost often involve 'trade-offs' (for example, enhancing efficiency may lead to increased material costs). However, iPSM achieves 'comprehensive optimization' of all three through structural innovation—higher efficiency, lighter weight, and lower costs. Moreover, this advantage has been validated by Tier 1 suppliers, laying the groundwork for large-scale implementation. For the new energy vehicle industry, the emergence of iPSM is not merely a technological innovation but also a reconfiguration of electric drive system design concepts. When 'coreless' becomes feasible, the boundaries of efficiency and cost are redefined. With further technological advancement and large-scale application, iPSM is poised to become the mainstream direction for future electric drive systems, bringing longer range, lower costs, and enhanced driving experiences to new energy vehicles.

Solemnly declare: the copyright of this article belongs to the original author. The reprinted article is only for the purpose of spreading more information. If the author's information is marked incorrectly, please contact us immediately to modify or delete it. Thank you.

|