From "imitation" to "being studied", foreign auto companies deeply reverse engineer China's new energy technologies

![]() 10/31 2024

10/31 2024

![]() 597

597

When Chinese auto companies encountered high tariff barriers in succession in the EU and North America, and after expressing at the Paris Motor Show that they "will not overthrow auto companies that have developed for more than 100 years," overseas media and institutions became more interested in China's new energy vehicles.

China's new energy vehicles have begun to be "studied" by foreign auto companies: In 2021, during a program broadcast on Japanese television, the highly anticipated "national god car" at the time, the Wuling Hongguang MINI EV, was "torn apart" and studied after being disassembled in its entirety, demonstrating the strength of Chinese electric vehicles in cost control.

Last year, Nikkei BP also disassembled a BYD Dolphin for a comprehensive study and compiled it into a book. And recently, according to Nikkei News, the Central Japan Economic and Industrial Bureau held a seminar to share the latest trends in pure electric vehicle technology. About 70 auto parts companies in central Japan visited the electric vehicle disassembly exhibition facilities and studied the body structure and component design features of Chinese-made electric vehicles.

Chinese auto companies once imitated Japanese and European designs during their early development stages, disassembling models and studying technologies to gain competitive advantages in the domestic market. However, in the current new energy sector, Chinese auto companies have become "research objects" and have begun reverse technology exports, leveraging advantages such as industrial chains and rapidly iterating technologies.

▍It's easy to disassemble cars, but difficult to "copy homework"

Several years ago, Japanese auto companies began to realize the importance of the new energy market and deployed relevant strategies. This organizational learning is obviously one of the means for them to further accelerate their transformation. And seeking inspiration from the success of China's new energy vehicles is also compelled by reality.

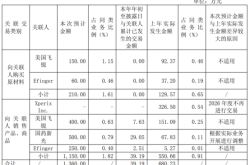

According to Japanese media reports, Sanyo Trading, which hosted this event, purchased 16 models, including BYD ATTO3, NIO's ET5, and ZEEKR 007, and disassembled over 90,000 components. Local seminars on EV technology trends have been held multiple times based on these disassembly results, and so far, more than 450 companies and over 6,000 people have visited to learn.

It is understood that the exhibition content is regularly updated, and plans are underway to add four new models, including Lixiang L9 and Hyundai IONIQ 6, at the end of this month.

Japanese companies that participated in this learning opportunity included well-known automakers and component companies, which sent research teams to gain a deeper understanding of the production lines, research and development processes, and design concepts of China's new energy vehicles. Such steps undoubtedly aim to shorten the gap between their own companies and China's new energy vehicles as quickly as possible by learning the most advanced technologies and concepts.

Participants in the seminar told the media that the standardization and localization of components are the backdrop for Chinese companies to produce low-cost electric vehicles. "Chinese manufacturers attach great importance to low-cost production," and in order to reduce costs, one approach is to promote the integration of components, which not only reduces weight but also costs, while also lowering the failure rate and facilitating later maintenance. Additionally, many of these manufacturers' components come from China's supply chain, with many parts being locally produced, and they share components across multiple models to reduce mold costs.

In addition to on-site studies, Nikkei BP has also conducted "thorough disassemblies" of multiple Chinese new energy vehicles and compiled books for the Japanese auto industry to learn from. Currently, it is known that Japan has conducted numerous disassemblies of Chinese-made new energy vehicles, including models such as the Wuling Hongguang MINI EV, Ora Good Cat, BYD ATTO3, NIO's ET5, and ZEEKR 007, as well as the recently highly anticipated Xiaomi SU7.

In addition to Japanese auto companies, major multinational auto companies are also "disassembling" China's new energy vehicles. It is understood that CaresoftGlobal, an American company specializing in helping auto companies reduce costs, disassembled a BYD Seagull and concluded that "with American manufacturing standards, the same vehicle would cost more than three times as much. BYD's ability to produce such low-cost yet high-quality vehicles is not a miracle but a reflection of efficiency."

Mercedes-Benz Research and Development Center also specially approved funding last year to independently disassemble popular Chinese new energy vehicles. The first model to be disassembled was the ZEEKR 001. Furthermore, Rivian CEO RJ Scaringe, the electric vehicle startup, stated at a recent event that the company purchased and disassembled a Xiaomi SU7, primarily to study how Rivian could imitate and improve its manufacturing costs.

In the European market, Reuters described the opening of the Paris Motor Show as a "critical moment": On the one hand, struggling European auto companies need to prove that they are still competitive; on the other hand, Chinese auto companies hope to gain a foothold in the fiercely competitive market. Meanwhile, the European electric vehicle industry collectively faces a dilemma of weak demand, intensifying competition between Chinese and European auto companies.

▍Route "swinging" becomes the biggest "damping"

A Japanese automotive expert believes that "simple disassembly and research cannot solve the root problem. The key lies in establishing a research and development system and business model that adapts to the new era." This sentiment reflects the real issues facing Japanese auto companies: The long-standing inertia does not create an insurmountable technological gap but rather poses challenges in rapidly switching mindsets and development philosophies.

Japanese auto companies have been somewhat ambivalent about developing electric vehicles, and have even been labeled as resistant. Toyota, Honda, and Nissan essentially represent the route choices of Japanese auto companies.

Taking Toyota as an example, in 2020, Toyota Motor President Akio Toyoda warned, "If the auto industry transitions too hastily to electric vehicles, the current business model of the auto industry will collapse."

In 2022, Akio Toyoda said in an interview, "Most people in the auto industry are the 'silent majority.' They want to know if electric vehicles as a sole option are truly viable, but they dare not voice their doubts loudly because electric vehicles are considered the general trend." This is not just Toyota's view; Honda CEO Takahiro Hachigo has also stated that electric vehicles and autonomous driving will not become mainstream in the short term.

However, in 2021, Toyota still launched a new energy strategy, planning to invest $35 billion by 2030 in developing electric vehicles. It also plans to invest an additional $35 billion in the continuous development of hybrid, plug-in hybrid, and hydrogen fuel cell vehicles.

By the end of 2030, Toyota expects annual sales of pure electric vehicles to reach 3.5 million. To achieve this, Toyota plans to launch 30 pure electric vehicle models by 2030. However, given its hesitation in the transition to electrification and even "swinging technology routes," the effectiveness of this forced transformation remains to be seen.

Faced with the strong rise of China's electric vehicles, it is evident that Japanese auto companies have realized the severity of the issue and have begun to take measures to catch up. However, it is not optimistic whether Japanese auto companies can recapture their former glory and continue to lead the world in the era of electric vehicles.

China's electric vehicle industry has already established a certain first-mover advantage and built high competitive barriers in terms of technology, market, and scale. Japanese auto companies need to overcome internal and external resistance to transform. Internally, they need to break away from the mindset and organizational structure inherited from the traditional fuel vehicle era and reestablish a new mechanism that adapts to the development of electric vehicles. Externally, they need to secure government policy support and consumer recognition. However, without the courage to make drastic changes, it is not easy for an elephant to turn around.

As a Japanese engineer interviewed said, the advantage of China's new energy vehicles is no longer simply cost-effectiveness but rather a complete industrial ecosystem, from independent research and development of core components to a comprehensive supply chain system and cost advantages brought about by large-scale production. These are not technologies that can be easily obtained through simple imitation. If Japanese auto companies continue to "swing" and constantly learn by disassembling cars, they will only become increasingly desperate.

Typesetting by Yang Shuo | Image Sources: Shutterstock, Nikkei BP, Nikkei Asian Review