Is AITO R7 the most powerful EREV in the Huawei ecosystem?

![]() 11/13 2024

11/13 2024

![]() 646

646

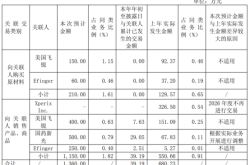

If there are no unexpected developments, HarmonyOS Auto will release its second mid-to-large-sized EREV SUV, the AITO R7 EREV, before March next year, following the AITO M7. The new vehicle has already completed its application with the Ministry of Industry and Information Technology and will likely make its debut at the Guangzhou Auto Show on November 15. Currently, there is limited information available about the AITO R7 EREV, but with Chery providing its internal combustion engine technology, the self-developed range extender is undoubtedly the main attraction. After all, Huawei's EREV technology has already gained market recognition with the AITO series. Will the AITO R7 EREV bring something different? Additionally, XPeng has confirmed its EREV route, while Changan's Kunlun 1.5T and Li Auto's Xincheng Power have their respective technical advantages. Now, with Chery's technical support, is Huawei still the most powerful EREV player?

Generating electricity with higher thermal efficiency, will the AITO R7 have 2 liters less fuel consumption than the Li Auto L7 in low battery mode?

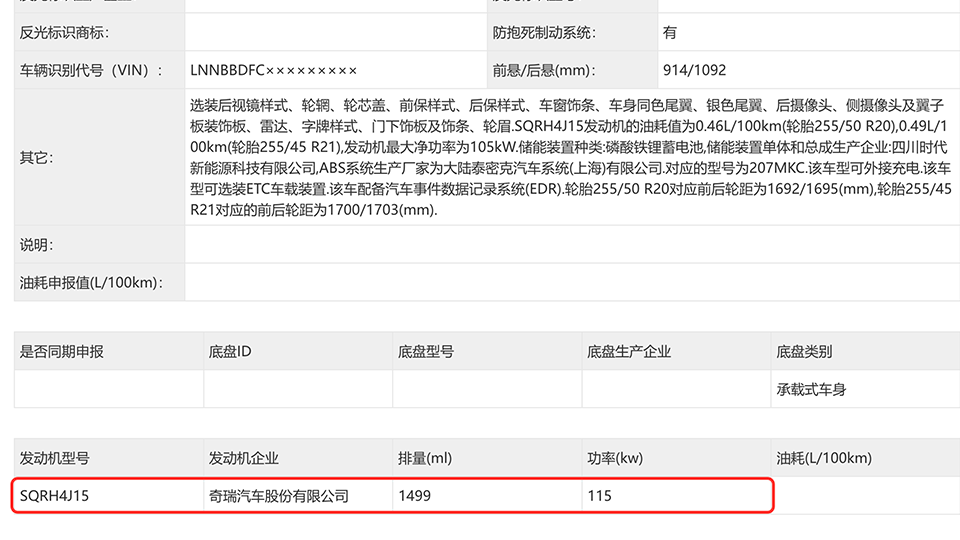

The SQRH4J15 engine will be familiar to drivers who have seen this code, as it is Chery's fifth-generation internal combustion engine and the same range extender model used in the Star Era ET. Let's start with a question: Can the AITO R7 rely on this range extender to surpass Huawei's technology by a wide margin? It's important to note that in more complex driving conditions involving different driving scenarios, internal combustion engines cannot always operate within their most efficient range, making an objective comparison challenging. However, as a range extender used solely for power generation, comparisons become much clearer by focusing on generation efficiency. In other words, under the same fuel consumption, the more thorough the combustion, the higher the fuel-to-electricity conversion rate, which ultimately tests thermal efficiency.

So, how can thermal efficiency be improved? Since EREV technology does not require direct drive from the internal combustion engine, the design can fully adopt a narrow and long cylinder block, completely eliminating any low-torque operating range. This design allows the piston to travel further due to inertia, essentially continuously attempting to make the expansion ratio effectively greater than the compression ratio. Continuing with this approach, since the combustion chamber needs to perform work for a longer duration, the intake valve can be closed earlier (deep Miller cycle). While elongating the cylinder block, expanding the combustion chamber volume undoubtedly facilitates more complete combustion, which is achieved by enlarging the cylinder block. Therefore, the mainstream range extenders on the market currently feature narrow and long cylinder blocks, with the ratio of stroke to bore becoming increasingly larger. Huawei's H15RT and Changan's JL469ZQ1 follow the same logic. Chery has set the bore of this range extender to 72mm and the stroke to 92mm, resulting in a bore-to-stroke ratio exceeding 1.27, which is more extreme than the 1.2 ratio of the AITO M7 and the 1.16 ratio of the Li Auto L7. Since everyone is now making narrow and long cylinder blocks, what other technologies has Chery incorporated into its fifth-generation engine?

The answer still lies in improving thermal efficiency. Technologies such as integrated exhaust manifolds in the cylinder head, variable geometry turbochargers, 350Bar high-pressure direct injection, and water-cooled intercoolers have been fully validated in the fourth-generation models. The new model achieves a compression ratio of 16. The mechanically driven variable oil pump pushes the slider to change the oil pump displacement in advance to meet the oil demand of the combustion chamber under different operating conditions, which is an indispensable technology for fully lubricating long-stroke cylinder blocks. How can the issues of high fuel consumption and knocking, which often occur in such cylinder blocks, be resolved? Injecting high-octane gasoline is the simplest and most direct solution to inhibit premature combustion of the fuel-air mixture. However, Chery, which still insists on high-pressure direct injection, proposes optimizing the intake port design and fuel-air mixture tumble in the combustion chamber. By designing a secondary combustion chamber next to the main combustion chamber, a small amount of the prematurely ignited fuel-air mixture is pushed into the main combustion chamber, where it ignites a larger amount of lean fuel-air mixture. Even without higher direct injection pressure, uniform ignition can be achieved more smoothly, resulting in energy savings. This solution not only resolves the tumble pressure in the main combustion chamber, reducing the risk of carbon deposition, but also suppresses knocking, eliminating the dependence on high-octane gasoline and saving vehicle operating costs to a certain extent. When these technologies are combined, the thermal efficiency reaches an impressive 44.5%, merely 0.11% higher than Changan's Kunlun EREV 1.5T, which was released in the second half of this year. However, Chery's technology debuted 15 months earlier.

Considering this range extender as a whole, the effect is already very evident: the combustion chamber achieves maximum combustion, so fuel consumption in low battery mode will not be too high. As seen in the Star Era ET, even with a curb weight of 2.1 tons, fuel consumption is only around 5.2 liters per 100 kilometers in low battery mode. For the AITO R7 EREV, which weighs 2.298 tons, at least 200kg heavier than the AITO M7 and Li Auto L7, it is highly likely to use CATL's 39kWh Xiaoyao battery. Considering the charging and discharging performance of this battery, it is believed that the new vehicle's fuel consumption in low battery mode will also be around 5 liters.

Does Chery currently perform better when burning 1 liter of fuel to generate electricity?

To some extent, fuel consumption is an important indicator of engine technology advancement. This is one of the reasons why traditional automotive giants like Audi, Toyota, Nissan, and Ford, who dominated the fuel era, have consistently tried to achieve higher thermal efficiency in internal combustion engines. The same logic applies to current EREV technology.

The growing popularity of EREV technology is largely attributed to its ability to easily achieve driving ranges exceeding 1,000 kilometers. Before the rise of electric vehicle battery, motor, and controller technology, the combination of a large range extender and a small battery was generally sufficient. However, range extenders were often not specifically tuned, similar to how race cars require specially strengthened and forged crankshafts. After re-examining several inherent issues with range extenders, narrow and long cylinder blocks can be made smaller in both displacement and volume. Even without a large battery, driving range can still exceed 1,000 kilometers. Regarding the different technologies used by automakers to improve engine thermal efficiency, where does the SQRH4J15 in the AITO R7 EREV stand in the market? It is certain that this technology is at least one generation ahead of the Dongan powertrain used in the XPeng G9 EREV. The Dongan 1.5T range extender chosen by XPeng uses dual injection, similar to traditional internal combustion engines. While the AITO H15RT, which employs manifold injection technology, requires high-octane gasoline to resolve knocking, it at least allows the fuel-air mixture to mix in advance through the manifold, eliminating the need for complex tumble mixing guidance within the narrow combustion chamber. Moreover, with a bore of 73.5mm and a stroke of 88.32mm, along with technologies such as low-pressure EGR, intake VVT, electronic water pumps, and multi-point fuel injection, the Dongan powertrain is at least one generation ahead of XPeng's EREV.

As mentioned earlier, narrow and long cylinder blocks are currently the mainstream design for range extenders in the market. The remaining differences lie in the combustion technologies and driving experience. Li Auto's Xincheng Power employs technologies such as VVT, ETC, dual balance shafts, and roller rocker arms to maintain high efficiency and stability across different operating conditions. Additionally, components like plastic intake manifolds, clamshell exhaust manifolds, and plastic cylinder head covers reduce weight while improving cooling efficiency. Coupled with technologies like tightly coupled three-way catalytic converters, roller rocker arms, and hydraulic tappets, long lifespan and low emissions are significant advantages of this technology. However, it also requires high-octane gasoline to resolve knocking issues. Changan's Kunlun EREV, released in the second half of this year, follows a similar design philosophy but offers an even more extreme stroke-to-bore ratio and an additional electronic oil pump technology, similar in principle to the variable oil pump technology in the AITO R7 EREV. Essentially, it is still directly connected to the engine crankshaft but cleverly builds pressure in the entire oil system in advance. For example, when the door is opened, the electric motor starts to establish lubrication for the range extender, reducing wear on the narrow and long cylinder block. Besides this technology, Changan has also introduced active stop-start piston control technology, which actively intervenes in the start-stop process of the range extender, positioning the piston at the point of minimum cylinder pressure and resistance during startup. However, this is not a new technology; Mazda has been using the i-STOP automatic start-stop system for years.

From a technical perspective, we can roughly determine the position and level of the AITO R7, backed by Chery technology, in the overall EREV market. Higher thermal efficiency means more complete combustion with the same amount of fuel, generating more electricity. Let's do a quick calculation. Without considering energy loss, the AITO M7 has a fuel tank capacity of 56 liters and a 40kWh battery pack, translating to approximately 3.13kWh of electricity generated per liter of fuel, resulting in nearly 175kWh of battery pack capacity when full. The Li Auto L7 has a 65-liter fuel tank and a 42.8kWh battery pack, generating approximately 3.3kWh of electricity per liter of fuel, equating to about 214kWh of battery pack capacity when full. The AITO R7 generates around 3.65kWh per liter. Considering that the new vehicle may use CATL's 39kWh Xiaoyao battery and is designed for a maximum pure electric range of 400 kilometers, it will undoubtedly have an advantage. Therefore, even without relying on a large 50kWh battery like XPeng's EREV, the AITO R7 can fully utilize the advantages of its range extender to achieve greater electricity consumption than large battery packs, resulting in a longer combined driving range and lower fuel consumption in low battery mode.

However, in the concept of EREV + small battery, we need to be concerned about the higher frequency of charge-discharge cycles for small batteries compared to large battery packs. Battery durability and degradation rate are issues that warrant attention in the future. According to a recent report by the China Automotive Technology and Research Center, comparing the Tesla Model 3 and Li Auto ONE, both with over 100,000 kilometers on the odometer, the latter's battery degraded by nearly 25%, 15% more than the former. Therefore, the center reached an awkward conclusion: among pure electric, plug-in hybrid, and extended-range power systems, extended-range batteries show the most obvious degradation. This is because, from a driving logic perspective, extended-range batteries undergo more charge-discharge cycles than pure electric and plug-in hybrid batteries. Currently, there are roughly two solutions to this issue. One is to fully utilize the high thermal efficiency of the range extender to increase the mandatory battery-preserving SOC threshold, thereby extending the battery's healthy lifespan by maximizing the range extender's power generation efficiency. The other solution involves innovative battery technology, which primarily tests the technical proficiency of future battery manufacturers.