How to Choose a 'Small Battery'? Camel Battery Leads the New Trend of New Energy Auxiliary Batteries

![]() 12/04 2024

12/04 2024

![]() 658

658

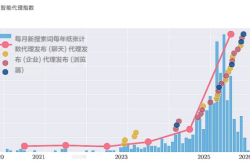

Against the backdrop of the booming new energy vehicle market, Zhao Zhiguo, the spokesperson and chief engineer of the Ministry of Industry and Information Technology, recently revealed that in the past three months, the sales share of new energy passenger vehicles has exceeded 50%, marking a new milestone in the new energy vehicle market. In the first three quarters of this year, the production and sales of new energy vehicles reached 8.316 million and 8.32 million units, respectively, with year-on-year increases of 31.7% and 32.5%, demonstrating the strong momentum of the new energy vehicle industry.

As an important component of new energy vehicles, batteries play a crucial role. New energy vehicles are not only equipped with high-voltage power batteries for driving motors but also require a 12V low-voltage auxiliary battery to start the high-voltage controller and provide power for electrical equipment such as lights, instruments, control systems, and car audio. Furthermore, in emergency situations, when the power battery fails, the auxiliary battery can provide power to the vehicle's safety system, helping the vehicle activate hazard lights, pull over, and ensure the safety of occupants.

Faced with a plethora of battery brands on the market, how should car owners make a wise choice? Camel Battery, with its unique technological advantages, has tailor-made the iEV series of new energy low-voltage auxiliary batteries for new energy vehicles, leading the new trend of new energy auxiliary batteries.

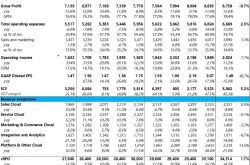

Camel's iEV series of new energy low-voltage auxiliary batteries have achieved significant breakthroughs in five areas: positive lead paste formulation, negative electrode formulation, ultra-low-resistance separator, grid, and electrolyte. Among them, the high-performance positive lead paste formulation and curing process are highlights of the Camel iEV series. They can significantly enhance the molecular chain connections between positive active materials, improve the active material and grid corrosion layer, reduce the internal resistance at the interface, and thus improve the rechargeability after overdischarge and cycle life of the battery.

Furthermore, the Camel iEV series has optimized the addition ratio of negative surface active agents, effectively improving the battery's charging acceptance performance. To address the challenges of long charging times and low charging efficiency in low-temperature environments, Camel Battery has independently developed high-conductivity collector grid technology and high-activity composite electrolyte additives. The application of these two technologies not only enhances the binding force of the lead paste, mitigates the softening rate of deeply discharged positive active materials but also significantly improves the battery's cycle life and charging recovery ability in low-temperature environments.

Currently, Camel's iEV new energy low-voltage auxiliary batteries encompass two major categories, EFB+ and AGM, with over ten different models to meet the personalized needs of different new energy vehicles. Meanwhile, Camel Battery has established over 110,000 service terminals nationwide, covering major provinces and cities in China, providing convenient and efficient services for new energy vehicle owners.

With the continuous development of the new energy vehicle market, Camel Battery will continue to deepen its involvement in the field of new energy auxiliary batteries, providing more intelligent and scenario-based application examples for new energy vehicle owners, contributing to a brighter future for the new energy vehicle industry.